Preparation method of lead sulfide colloid quantum dots

A technology of colloidal quantum dots and lead sulfide, which is applied in the field of preparation of semiconductor nanomaterials, can solve the problems of complex synthesis process of quantum dots and poor repeatability of results, and achieve the effects of easy control, good reproducibility and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

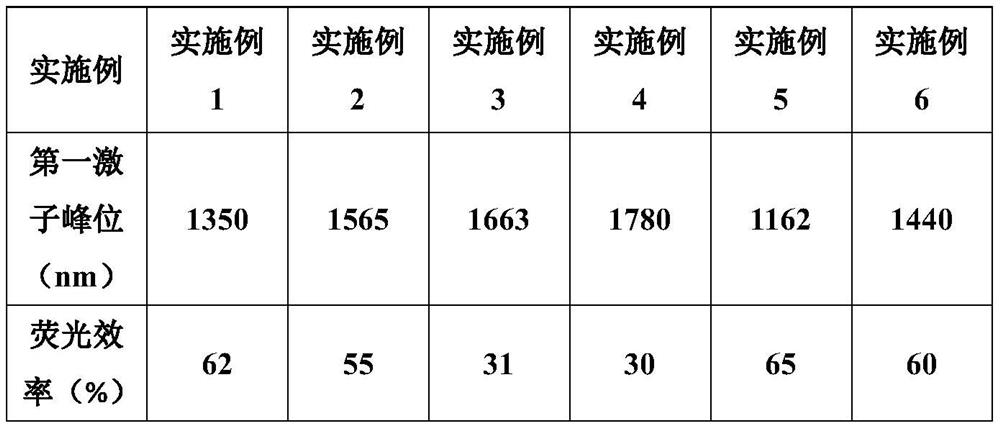

Embodiment 1

[0020] A: Weigh 1.2g sodium chloride and 6g basic lead acetate (Pb(CH 3 COO) 2 ·Pb(OH) 2 ), and were dissolved in 15ml of distilled water respectively to prepare 1.37M and 0.7M solutions; then the two solutions were mixed and reacted at 80°C for 15min, and the white precipitate was rinsed with distilled water and dried to remove water to obtain basic lead chloride; Weigh 0.278g (0.001mol) of the synthesized basic lead chloride and 15ml of octylamine / oleic acid / octadecene mixed reagent, heat and react at 130°C for 30min under nitrogen protection, and then vacuumize for 30min to obtain the lead precursor solution;

[0021] B: Mix 0.032g (0.001mol) of elemental sulfur with 3.5ml of oleylamine at room temperature, and dissolve it quickly by ultrasonication to obtain a 0.286M sulfur precursor solution; then quickly inject the sulfur precursor solution into the step under a nitrogen atmosphere In the lead precursor solution described in A, cooled to 70°C; finally, cooled to 15°C ...

Embodiment 2

[0024] A: Weigh 1.2g sodium chloride and 6g basic lead acetate (Pb(CH 3 COO) 2 ·Pb(OH) 2 ), and were dissolved in 15ml of distilled water respectively to prepare 1.37M and 0.7M solutions; then the two solutions were mixed and reacted at 80°C for 15min, and the white precipitate was rinsed with distilled water and dried to remove water to obtain basic lead chloride; Weigh 0.278g (0.001mol) of the synthesized basic lead chloride and 15ml of oleylamine / oleic acid / octadecene mixed reagent, heat and react at 130°C for 30min under nitrogen protection, and then vacuumize for 30min to obtain the lead precursor solution;

[0025] B: Mix 0.032g (0.001mol) of elemental sulfur with 3.5ml of oleylamine at room temperature, and dissolve it quickly by ultrasonication to obtain a 0.286M sulfur precursor solution; then quickly inject the sulfur precursor solution into the step under a nitrogen atmosphere In the lead precursor solution described in A, cooled to 90°C; finally, cooled to 15°C ...

Embodiment 3

[0028] A: Weigh 1.2g sodium chloride and 6g basic lead acetate (Pb(CH 3 COO) 2 ·Pb(OH) 2 ), and were dissolved in 15ml of distilled water respectively to prepare 1.37M and 0.7M solutions; then the two solutions were mixed and reacted at 80°C for 15min, and the white precipitate was rinsed with distilled water and dried to remove water to obtain basic lead chloride; Weigh 0.278g (0.001mol) of the synthesized basic lead chloride and mix it with 15ml of octylamine / oleic acid / octadecene mixed reagent, heat and react at 130°C for 30min under the protection of nitrogen, then vacuumize for 30min to obtain the lead precursor body solution;

[0029] B: Mix 0.032g (0.001mol) of elemental sulfur with 3.5ml of oleylamine at room temperature, and dissolve it quickly by ultrasonication to obtain a 0.286M sulfur precursor solution; then quickly inject the sulfur precursor solution into the step under a nitrogen atmosphere In the lead precursor solution described in A, cooled to 120° C.; f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com