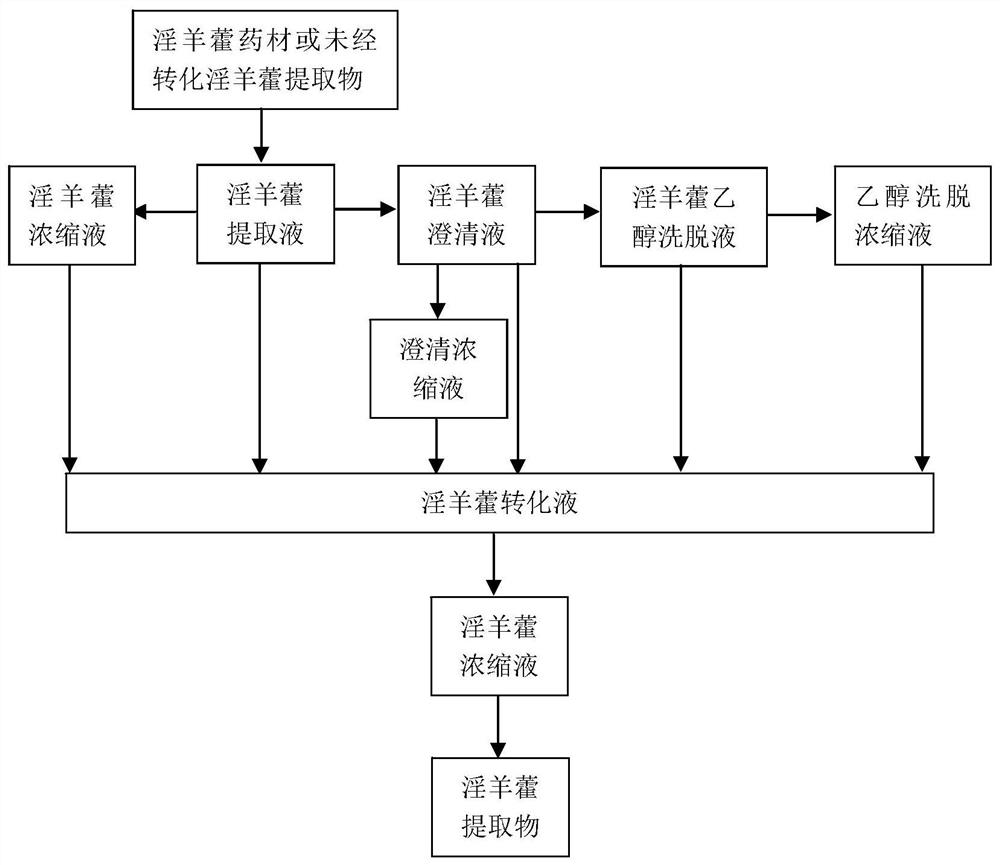

Process method for improving icariin yield

A process method, the technology of icariin, applied in the field of biological extraction, can solve the problems of high production cost of epimedium extract, shortage of wild epimedium resources, etc., achieve shortened production cycle, short cycle, cheap and easy to obtain reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put 300 kilograms of cut epimedium medicinal materials (0.55% icariin content) into a hot reflux extraction tank, and use 50% ethanol to reflux extract 3 times, the solvent consumption is respectively 4200L, 3000L, 3000L, each extraction 1.5h. Centrifuge to remove fine particles, combine the three extracts to a total of 9300L, cool down to (40±10)°C with cooling circulating water, add 93L of 1mol / L NaOH aqueous solution under stirring, keep at (40±10)°C for 2 hours, and use dilute hydrochloric acid Adjust the pH to 6.5. Concentrate under reduced pressure until the feed liquid has no alcohol smell and recover ethanol to obtain a concentrated liquid of about 1000L. Use 300kg AB-8 macroporous adsorption resin column for adsorption, sample loading flow rate 450L / h, wash away impurities with 600L pure water, then elute with 900L 70% ethanol, collect 70% ethanol eluate, concentrate to relative density 1.15, dried to obtain 16.4 kg of Epimedium extract, the content of icarii...

Embodiment 2

[0035] Put 500 kg of the cut epimedium medicinal material (0.55% icariin content) into a percolation tank, and use 7500 L of 50% ethanol for percolation extraction at a percolation speed of 40 L / h. A total of 6200 L of percolation liquid was collected, concentrated under reduced pressure until the feed liquid had no alcohol smell, recovered ethanol, and centrifuged to remove fine particles to obtain about 900 L of concentrated liquid. Cool down to (60±10)°C with circulating cooling water, add 1mol / L Na with stirring 2 CO 3 180L aqueous solution, kept at (60±10)°C for 12h, and adjusted the pH to 7.0 with acetic acid. Adsorb with 250 kg D101 macroporous adsorption resin column, flow rate 375L / h, wash away impurities with 750L pure water, then elute with 1000L 65% ethanol, collect 65% ethanol eluate, concentrate to a relative density of 1.09, dry , to obtain 25.8 kg of Epimedium extract, the content of icariin detected by HPLC is 14.3%. The total yield of icariin was 134.2%. ...

Embodiment 3

[0037]Put 3,000 kilograms of cut Epimedium herbs (with 0.25% icariin content) into 10 hot-reflux extraction tanks, decoct them with pure water for 3 times, and the solvent consumption for each tank is 4500L, 3600L, and 3600L respectively , extract 1.5h each time. Centrifuge to remove fine particles, combine the three extracts to a total of 105KL, pass cooling circulating water to cool down to below 80°C, use 4000 kg D101 macroporous adsorption resin column for adsorption, flow rate 16000L / h, wash with 6000L pure water to remove impurities, and then use 12000L Elute with 80% ethanol, collect the 80% ethanol eluate, concentrate under reduced pressure until the feed liquid has no alcohol smell, recover ethanol, and obtain a concentrated solution of about 2600L. Add 100L of 5mol / L KOH aqueous solution while it is hot under stirring, keep warm at (50±10)°C and stir for 30min, and adjust the pH to 6.0 with dilute sulfuric acid. Use 2000 kg D101 macroporous adsorption resin column f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com