Tandem type one-step rubber mixing system

A tandem, one-step technology, applied in the field of tandem one-step rubber mixing system, can solve the problems of low degree of automation of the production line, high probability of waste products, high labor intensity of workers, etc., to facilitate information management, improve physical properties, The effect of saving the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the purpose, structure and function of the present invention, a serial one-step rubber mixing system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

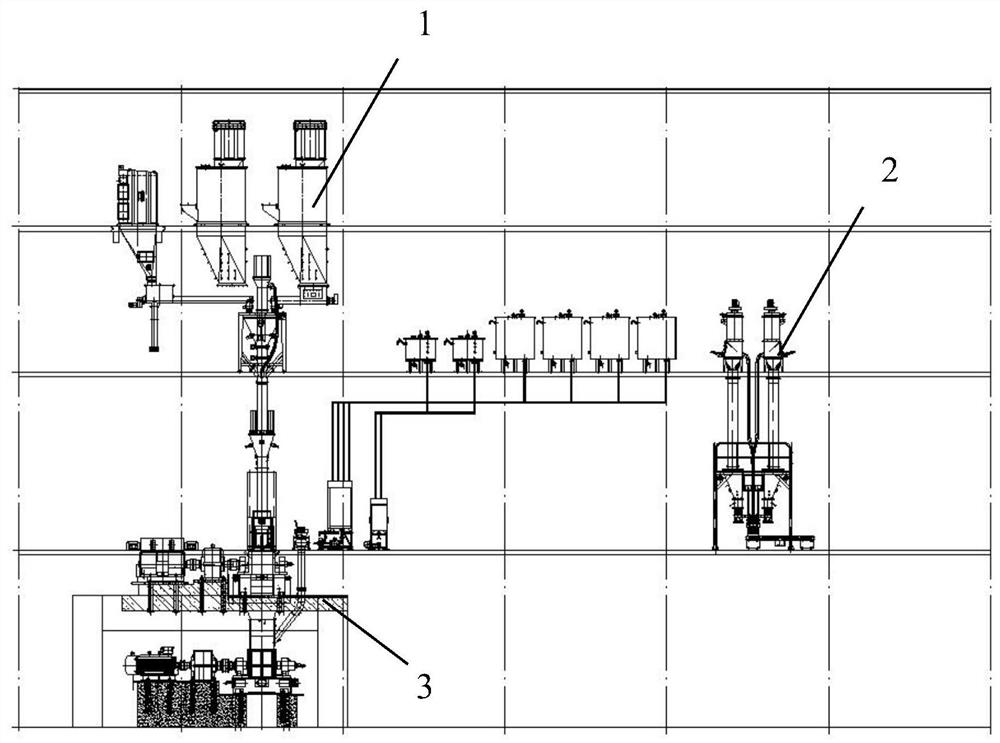

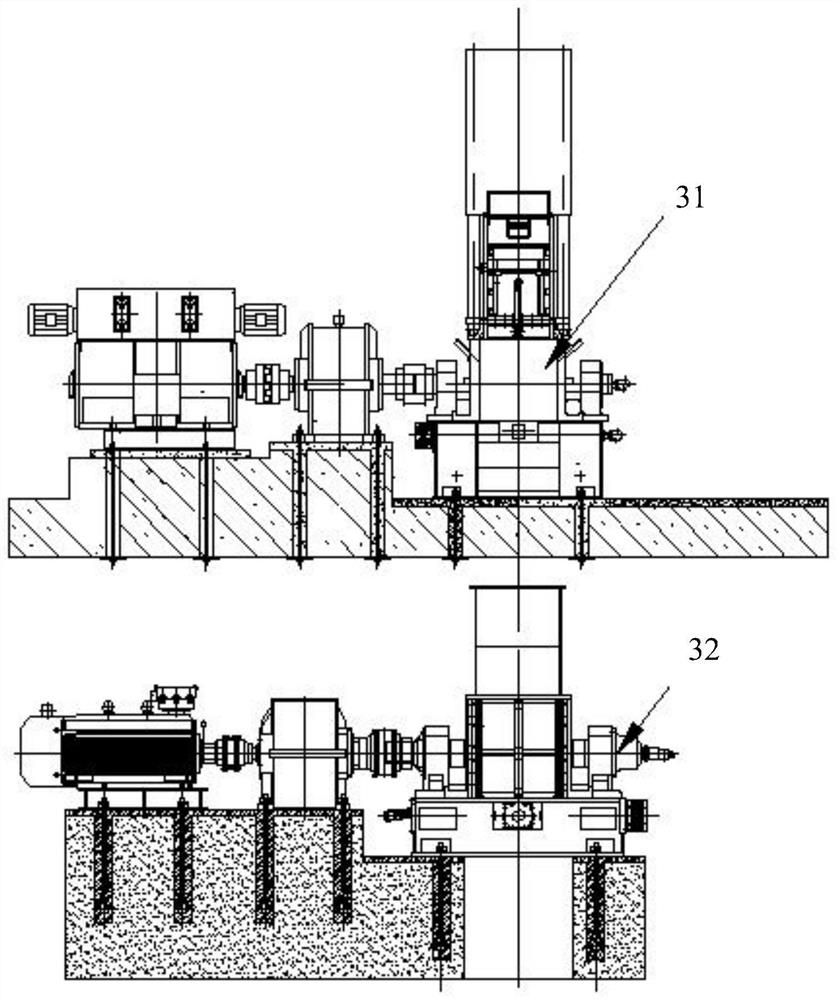

[0023] Such as Figure 1 to Figure 2 As shown, it is shown as a series type one-step rubber mixing system of the present invention, including an internal mixer upper auxiliary machine system 1 connected to a control system, a fully automatic small material automatic weighing system 2, and a series type internal mixer system 3 and automatic mill system. The rubber mixing system of the present invention cooperates with intelligent equipment and a control system to realize linkage control of the above equipment and realize a serial one-step rubber mixing process. Specifically, the upper auxiliary machine system 1 of the internal mixer has a four-layer three-dimensional structure, including a storage bin and a positive pressure co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com