Mechanical workpiece grinding and trimming device

A workpiece and trimming technology, which is applied in the field of mechanical workpiece grinding and trimming devices, can solve the problems of complex work of the adjustment device, increased operation difficulty, and easy operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

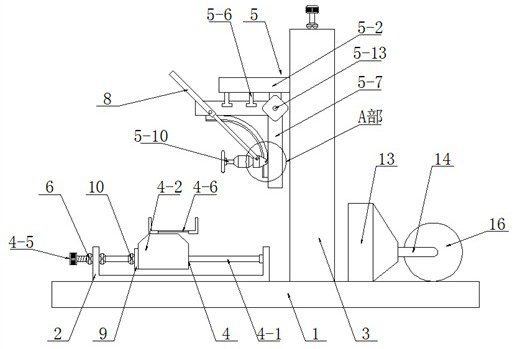

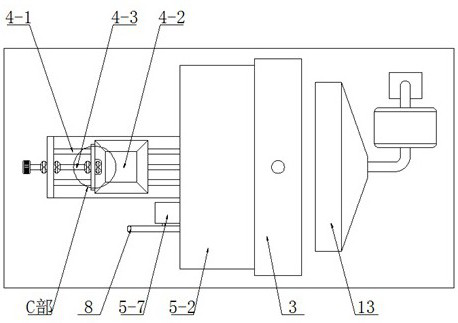

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] see as Figure 1-Figure 7 As shown, this specific embodiment includes a base 1, a No. 1 bracket 2, a No. 2 bracket 3, a workpiece fixing assembly 4, and a grinding and fixing assembly 5, wherein the base 1 is riveted with a No. 1 bracket 2, and the workpiece fixing assembly 4 is riveted on a No. 2 bracket 2, base 1 is riveted with No. 2 bracket 3, No. 2 bracket 3 is located on the right side of No. 1 bracket 2, and No. 2 bracket 3 is riveted with polishing and fixing assembly 5, and polishing and fixing assembly 5 is arranged on The top of the workpiece fixing assembly 4;

[0030] The workpiece fixing assembly 4 includes a No. 1 guide rod 4-1, a No. 1 fixing seat 4-2, a No. 1 screw rod 4-3, and a clamping claw 4-6, wherein the No. 1 guide rod 4-1 is riveted on the Above the No. 1 support 2, a No. 1 holder 4-2 is slidably arranged on the No. 1 guide rod 4-1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com