Laser automatic cutting machine for waste lithium battery module shell

A waste lithium battery and cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low work efficiency and low degree of automation, and achieve the effects of cost saving, firm adsorption, and thorough and efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

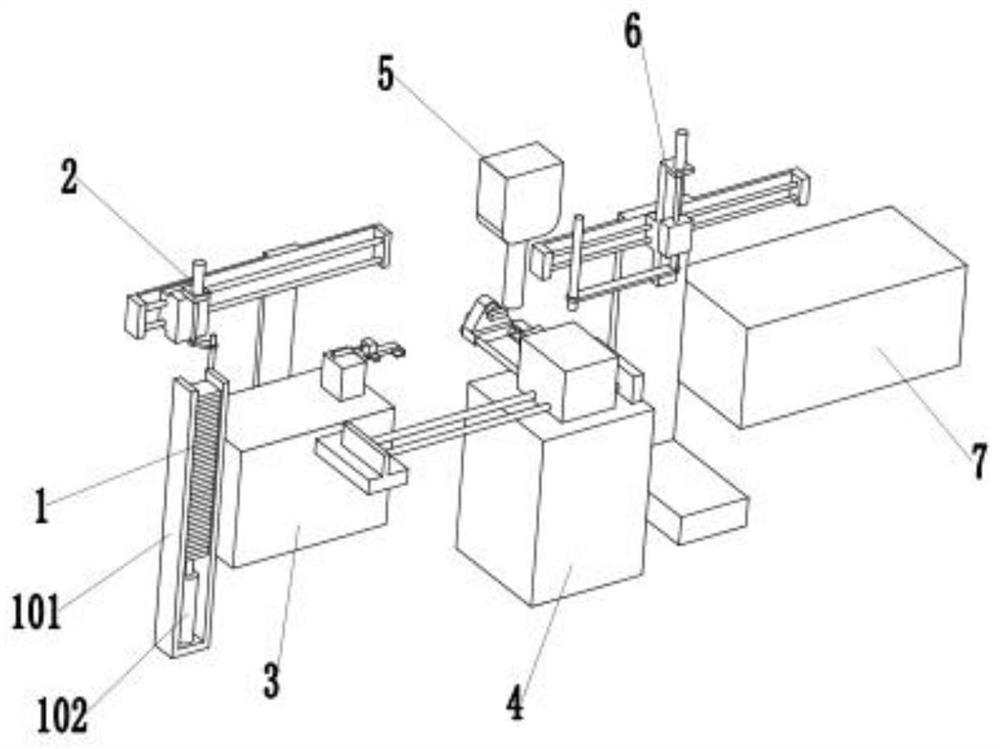

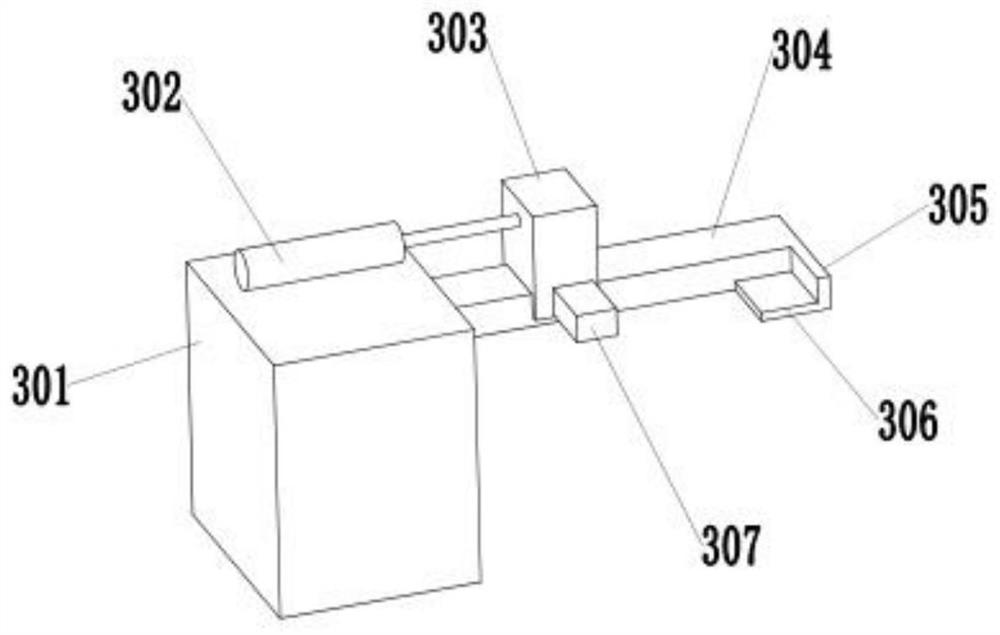

[0026] Such as Figure 1-5 As shown, a laser automatic cutting machine for waste lithium battery module shells includes a storage rack 1, a first feeding device 2, a feeding device 3, a clamping device 4, a laser cutting machine 5, and a second feeding device 6 , discharging platform 7, the bottom of described first feeding device 2 is provided with storage rack 1 and feeding device 3, and described storage rack 1 and feeding device 3 are respectively arranged on two sides of first feeding device 2 One side of the feeding device 3 is provided with a clamping device 4, a laser cutting machine 5 is provided above the clamping device 4, and a second delivery device 6 is provided on one side of the clamping device 4 , The lower end side of the second conveying device 6 is provided with a discharge platform 7 .

Embodiment 2

[0028] Such as Figure 1-5 As shown, a laser automatic cutting machine for waste lithium battery module shells includes a storage rack 1, a first feeding device 2, a feeding device 3, a clamping device 4, a laser cutting machine 5, and a second feeding device 6 , a feeding platform, the bottom of the first feeding device 2 is provided with a storage rack 1 and a feeding device 3, and the storage rack 1 and the feeding device 3 are respectively located at the two ends of the first feeding device 2 A clamping device 4 is provided on one side of the feeding device 3, a laser cutting machine 5 is provided above the clamping device 4, and a second feeding device 6 is provided on one side of the clamping device 4, A discharge table 7 is provided at the lower end side of the second conveying device 6 .

[0029] The material storage platform 1 includes a splint 101 and an electric push rod 102 for ejecting materials. The number of the splints 101 is two, and an electric push rod 102 ...

Embodiment 3

[0031] Such as Figure 1-5 As shown, a laser automatic cutting machine for waste lithium battery module shells includes a storage rack 1, a first feeding device 2, a feeding device 3, a clamping device 4, a laser cutting machine 5, and a second feeding device 6 , a feeding platform, the bottom of the first feeding device 2 is provided with a storage rack 1 and a feeding device 3, and the storage rack 1 and the feeding device 3 are respectively located at the two ends of the first feeding device 2 A clamping device 4 is provided on one side of the feeding device 3, a laser cutting machine 5 is provided above the clamping device 4, and a second feeding device 6 is provided on one side of the clamping device 4, A discharge table 7 is provided at the lower end side of the second conveying device 6 .

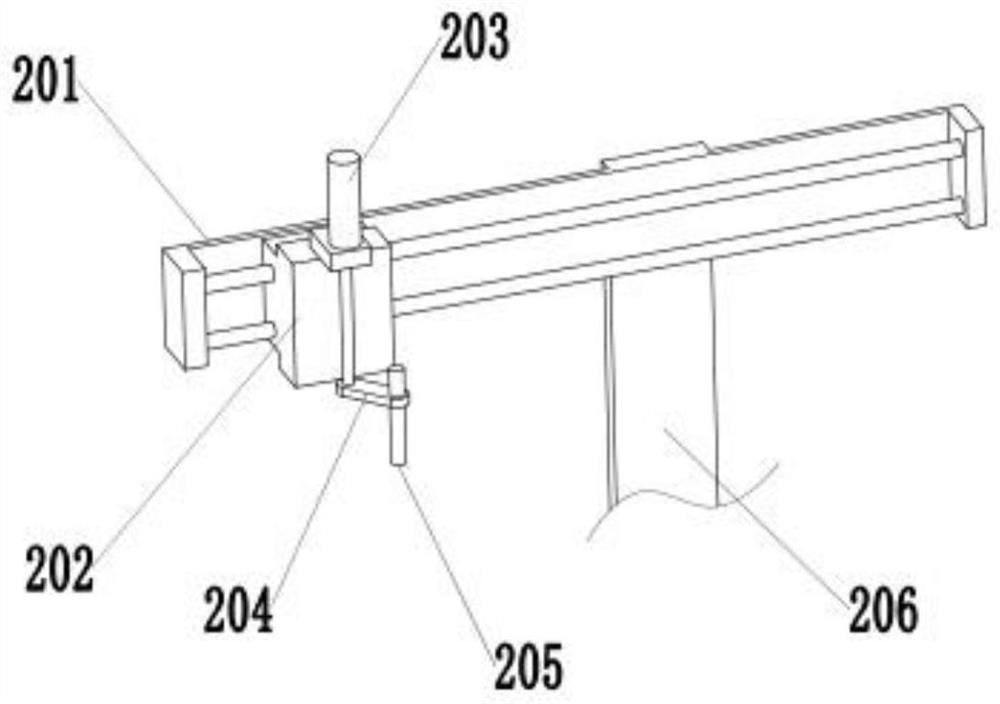

[0032] The first delivery device 2 includes a first slide rail 201, a first slider 202, a first electric push rod 203, and a first suction pipe 205, and the first slide rail 201 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com