Pneumatic actuator testing system

A technology of pneumatic actuators and testing systems, applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., can solve the problem of single function of the testing device and achieve the effect of improving the testing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

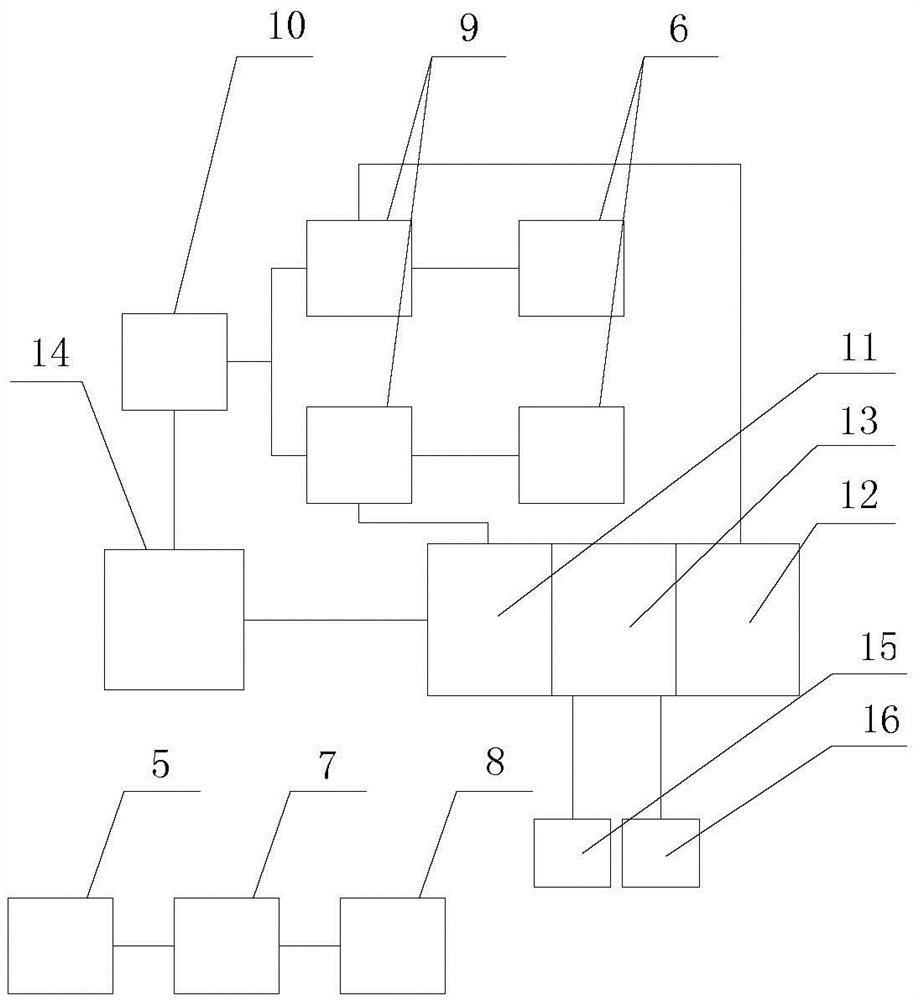

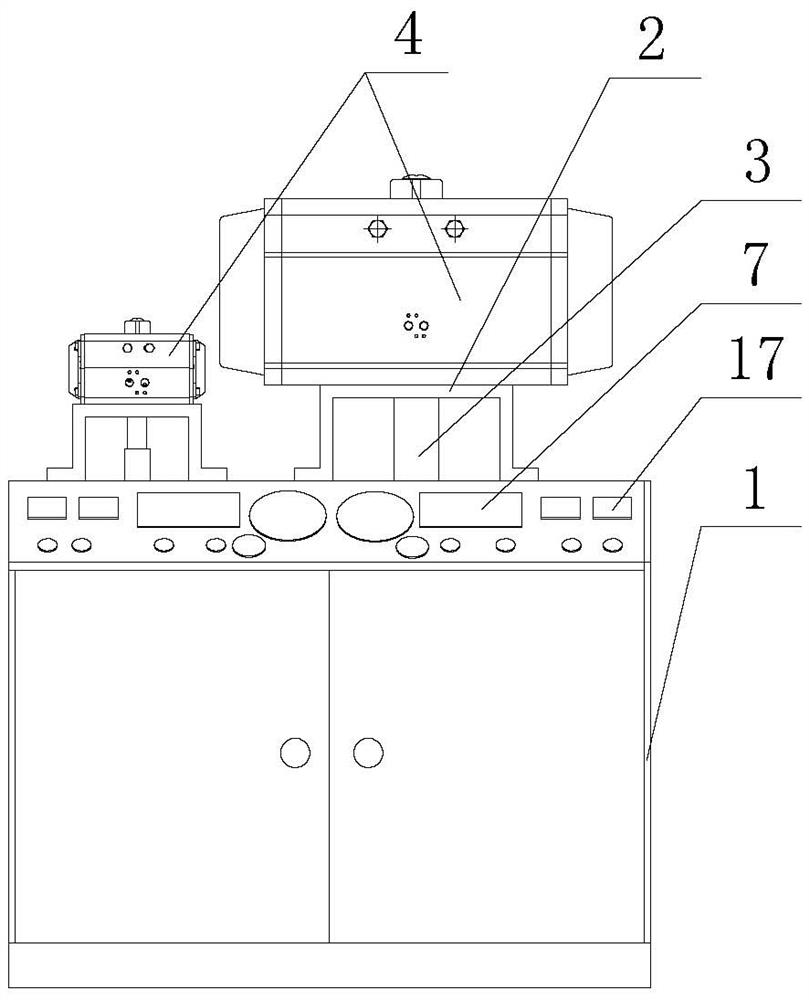

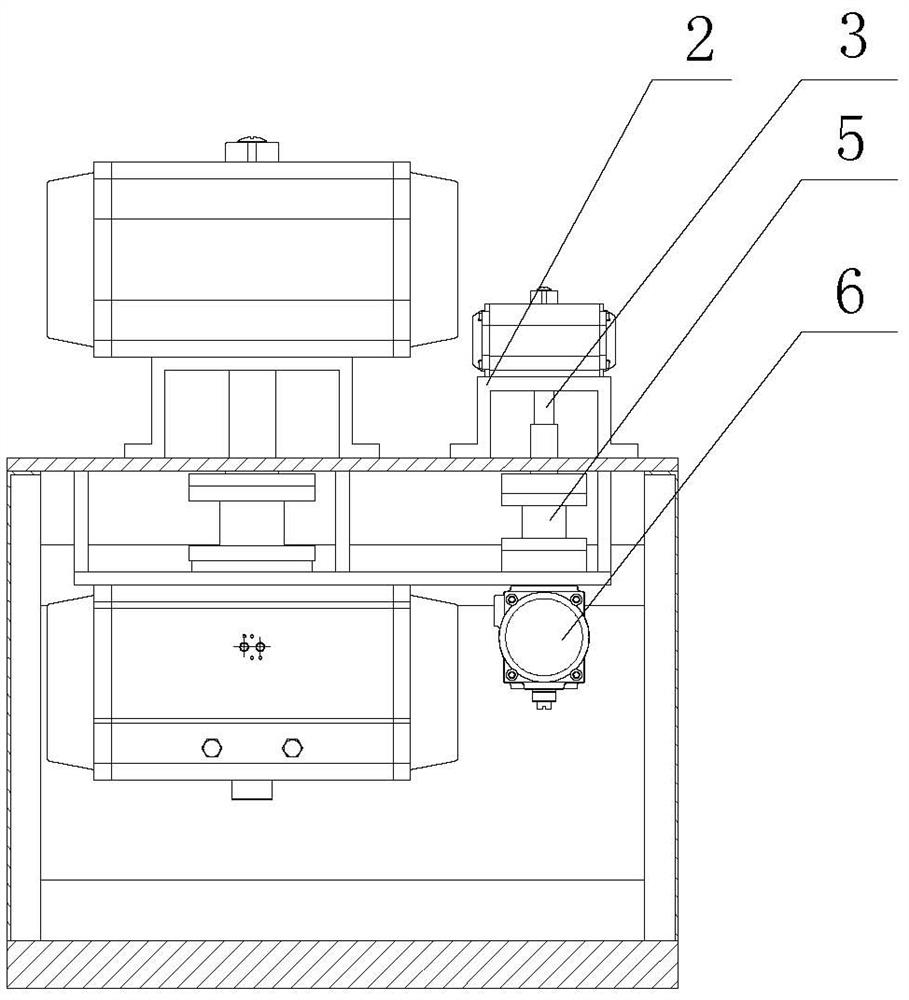

[0010] See figure 1 , figure 2 , image 3 As shown, a pneumatic actuator testing system includes a workbench 1, two test stands 2 are installed on the workbench 1, a rotatable transmission shaft 3 is installed on the test stand 2, and the upper end of the transmission shaft 3 is used to connect to the The detected pneumatic actuator 4, the lower end of the transmission shaft 3 is connected to one end of the torque sensor 5 located inside the test bench, the other end of the torque sensor 5 is connected to the load rotating cylinder 6, and the torque sensor 5 is also electronically connected to the torque meter 7, the torque meter 7 Connect the computer 8 through the data line, the torque meter 7 is installed on the workbench 1, the two torque sensors 5 and the load rotating cylinder 6 are respectively powered by the torque power supply 9, the test range is different, respectively 0-500NM and 0-50000NM, the torque The power supply 9 is electronically connected to the main po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com