Heat exchanger energy recovery device

An energy recovery device and heat exchanger technology, applied in the field of energy recovery device and heat exchanger energy recovery device, can solve problems such as low energy recovery rate, and achieve the effect of intelligent ventilation heat recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

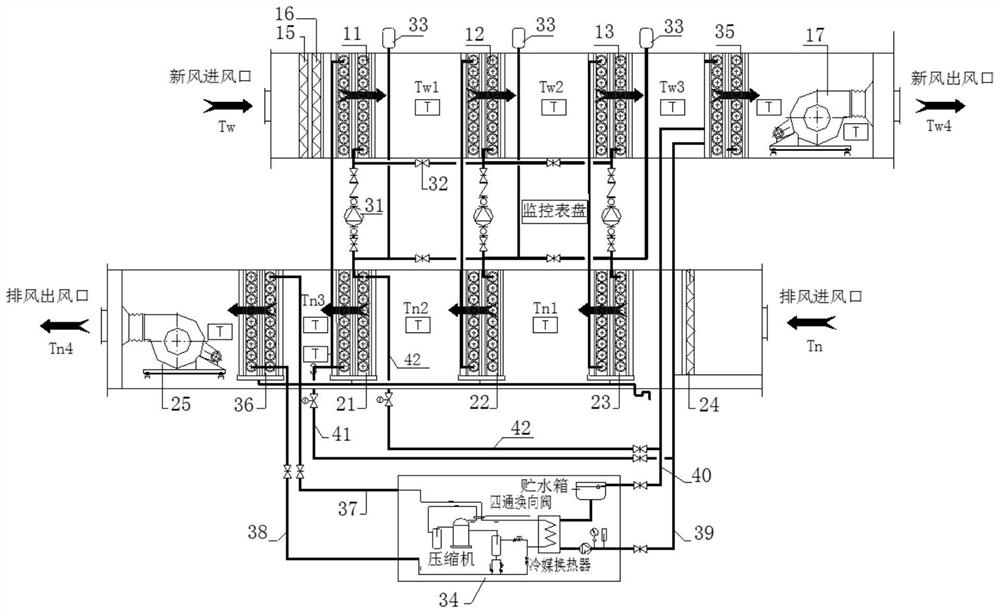

[0057] Example 1: see figure 1 , A heat exchanger energy recovery device of this embodiment includes a fresh air duct module, and a fresh air section power module 17, a fresh air section filter module, a fresh air section heat exchange module, a fresh air section power module, and a Heater 14;

[0058] The fresh air section filter module includes three stages of filtration, namely: primary filter I15, medium efficiency filter I16, and high efficiency filter, which are arranged in sequence according to the air inlet path;

[0059] The fresh air section heat exchange module includes three heat exchangers, namely, fresh air section heat exchanger I11, fresh air section heat exchanger II12, and fresh air section heat exchanger III13, which are arranged in sequence according to the air inlet path;

[0060] The fresh air duct module is a cylindrical air duct with an air inlet and an air outlet;

[0061] The power module 17 of the fresh air section adopts an electric fan. The electric fan h...

Embodiment 2

[0077] Embodiment 2: A heat exchanger energy recovery device of this embodiment includes a fresh air duct module, and a fresh air section power module 17, a fresh air section filter module, a fresh air section heat exchange module, and a fresh air section power module 17 sequentially arranged therein according to the air inlet path. Electric heater 14 for fresh air section;

[0078] The fresh air section filter module includes three stages of filtration, namely: primary filter I15, medium efficiency filter I16, and high efficiency filter, which are arranged in sequence according to the air inlet path;

[0079] The fresh air section heat exchange module includes three heat exchangers, namely, fresh air section heat exchanger I11, fresh air section heat exchanger II12, and fresh air section heat exchanger III13, which are arranged in sequence according to the air inlet path;

[0080] The fresh air duct module is a cylindrical air duct with an air inlet and an air outlet;

[0081] The po...

Embodiment 3

[0097] Embodiment 3: The heat exchanger energy recovery device described in this embodiment. The difference between this embodiment and Embodiments 1 and 2 is that the heat exchange medium used is different. The heat exchange module in the fresh air section and the heat exchange module in the exhaust section are different The number of heat exchangers is different. In this embodiment, the heat exchange medium is heat transfer oil, and the heat exchange module of the fresh air section and the heat exchange module of the exhaust air section both include two heat exchangers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com