Compression-resistant hyperbolic aluminum veneer

An aluminum veneer, hyperbolic aluminum technology, applied in building components, building insulation materials, shockproof and other directions, can solve the problem of unsatisfactory compressive performance of hyperbolic aluminum veneer, achieve installation firm performance guarantee, reduce product weight, The effect of improving compressive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

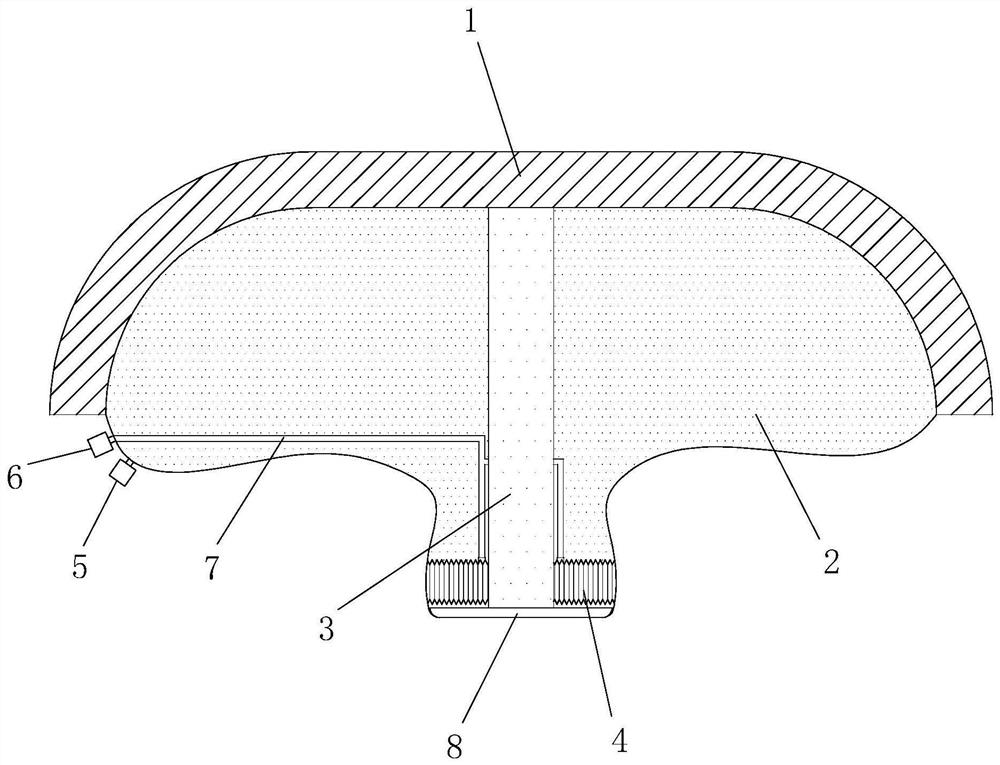

[0021] Such as figure 1 As shown, a compression-resistant hyperbolic aluminum veneer includes an aluminum veneer body 1 with a concave inner surface. The specific concave shape can be various, and the outer surface of the aluminum veneer body 1 is provided with an anti-oxidation coating. (not shown in the figure), the anti-oxidation coating is one of silicon carbide, titanium nitride, and silicon carbide, and the thickness is not less than 1mm. The inner surface of the aluminum veneer body 1 is bonded with the main airbag 2, and 2 The first airbag column 3 is erec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com