Preparation method and application of ganoderma lucidum mycelium polysaccharide

A technology of ganoderma lucidum mycelium and polysaccharides, applied in the fields of application, polysaccharide/gum-containing food ingredients, medical preparations containing active ingredients, etc., can solve the problems of low purity of ganoderma lucidum polysaccharides, high extraction cost, waste of raw materials, etc., and achieve comprehensive Good utilization effect, simplified process steps, and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

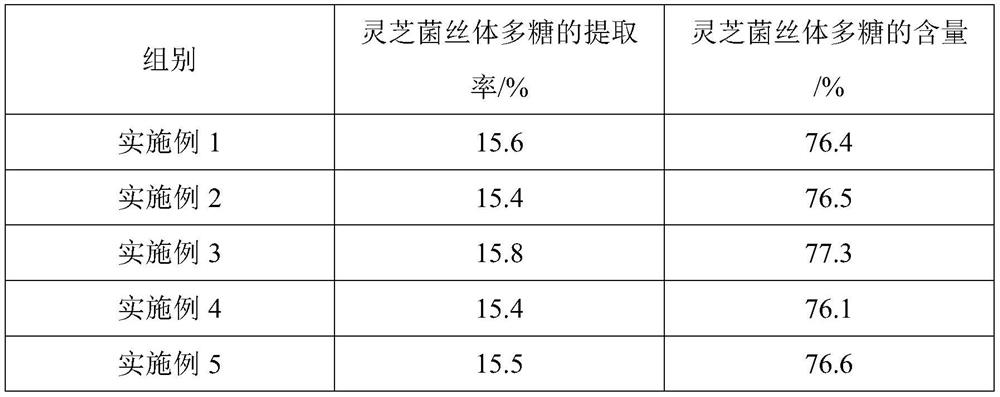

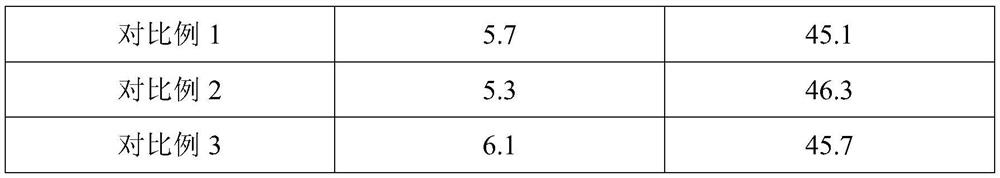

Examples

Embodiment 1

[0029] Embodiment 1, a kind of Ganoderma lucidum mycelia polysaccharide

[0030] The preparation method of described Ganoderma lucidum mycelia polysaccharide, comprises the steps:

[0031] S1, get the dried Ganoderma lucidum mycelium and put it into a pulverizer and pulverize to 8 μm, then add 8 times the amount of organic solvent and carry out degreasing treatment, the organic solvent is 2 by mass ratio by propylene glycol methyl ether, acetone and dimethyl sulfoxide: 4:1 composition, the degreasing treatment time is 1h, centrifuged, the lower layer is removed and dried at 50°C to obtain coarse powder of Ganoderma lucidum mycelium;

[0032] S2, get the Ganoderma lucidum mycelium coarse powder that step S1 makes, add the deionized water of 10 times amount, then carry out supercritical CO 2 Extraction, supercritical CO 2 The extraction conditions are: pressure 30Mpa, extraction temperature 50°C, extraction time 4h; filter to obtain water extract;

[0033] S3, take the water ...

Embodiment 2

[0036] Embodiment 2, a kind of Ganoderma lucidum mycelia polysaccharide

[0037] The preparation method of described Ganoderma lucidum mycelia polysaccharide, comprises the steps:

[0038] S1, take the dried Ganoderma lucidum mycelium and put it into a pulverizer to pulverize to 8.5 μm, then add 8.5 times the amount of organic solvent for degreasing treatment, the organic solvent is composed of propylene glycol methyl ether, acetone and dimethyl sulfoxide in a mass ratio of 3 : 5:2 composition, the degreasing treatment time is 1.5h, centrifuged, the lower layer of sediment is taken and dried at 55°C to obtain coarse powder of Ganoderma lucidum mycelium;

[0039] S2, get the Ganoderma lucidum mycelium coarse powder that step S1 makes, add 14 times of deionized water, then carry out supercritical CO 2 Extraction, supercritical CO 2 The extraction conditions are: pressure 31Mpa, extraction temperature 53°C, extraction time 4.2h; filter to obtain water extract;

[0040] S3, tak...

Embodiment 3

[0043] Embodiment 3, a kind of Ganoderma lucidum mycelia polysaccharide

[0044] The preparation method of described Ganoderma lucidum mycelia polysaccharide, comprises the steps:

[0045] S1, get the dried ganoderma lucidum mycelium and put it into a pulverizer and pulverize to 9 μm, then add 9 times the amount of organic solvent and carry out degreasing treatment, the organic solvent is 2 by mass ratio by propylene glycol methyl ether, acetone and dimethyl sulfoxide: 6:1 composition, the degreasing treatment time is 2 hours, centrifuged, the lower layer is removed and dried at 58°C to obtain coarse powder of Ganoderma lucidum mycelium;

[0046] S2, get the Ganoderma lucidum mycelium coarse powder that step S1 makes, add 16 times of deionized water, then carry out supercritical CO 2 Extraction, supercritical CO 2 The extraction conditions are: pressure 33Mpa, extraction temperature 55°C, extraction time 4.5h; filter to obtain water extract;

[0047] S3, take the water extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com