A kind of preparation method of composite zircon powder

A technology for compounding zirconium and zircon powder, which is applied in the direction of chemical instruments and methods, zirconia, mixers, etc., can solve the problems of improved mixing uniformity, cumbersome operation, and high labor intensity, so as to improve fire resistance and simplify operation Process, the effect of improving the fineness of whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

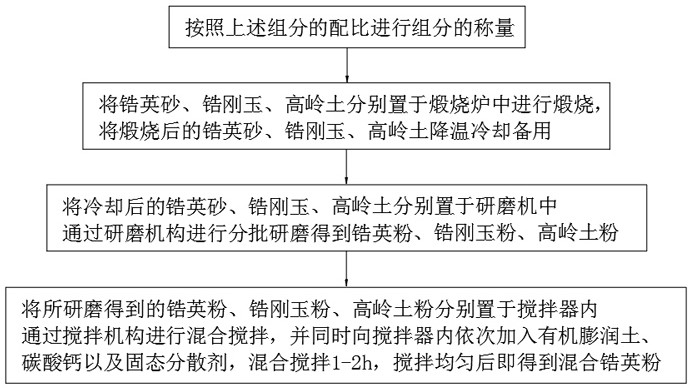

[0040] see figure 1 , A preparation method of composite zircon powder, comprising the following components in parts by mass: 55-70 parts of zircon sand, 15-20 parts of zirconium corundum, 5-15 parts of kaolin, 10-10 parts of Organobentonite, 3-5 parts of calcium carbonate, 2-5 parts of solid dispersant, the preparation method thereof is: comprising the following steps:

[0041] S1. Weigh the components according to the proportions of the above components;

[0042] S2, place zircon sand, zirconium corundum, and kaolin respectively in a calciner for calcination, and cool and cool the calcined zircon sand, zirconium corundum, and kaolin for use;

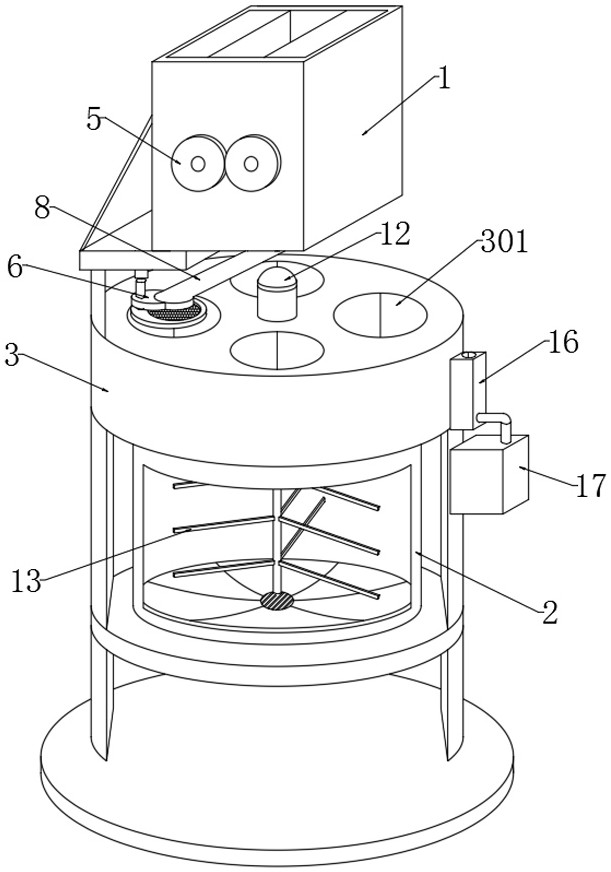

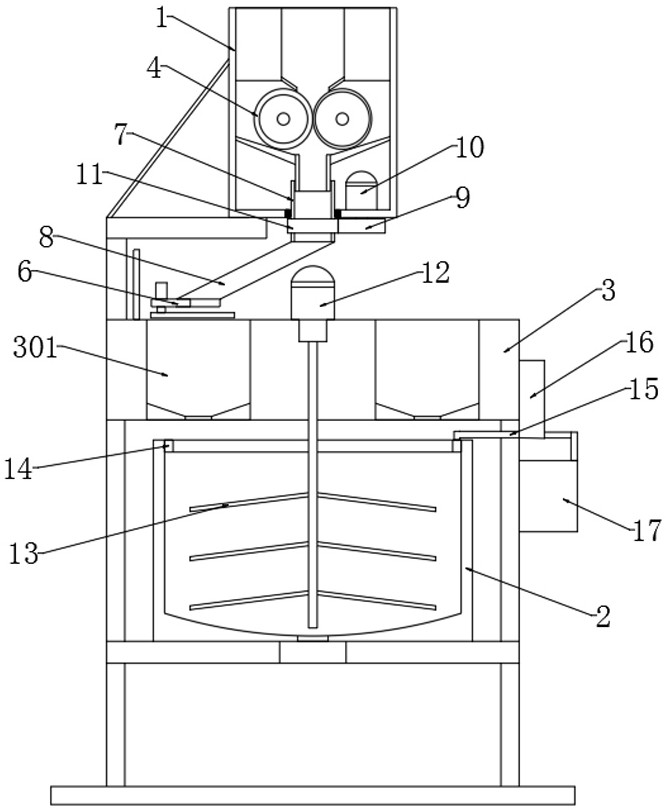

[0043] S3, place the cooled zircon sand, zirconium corundum, and kaolin in S2 respectively in the grinding machine 1 and grind them in batches through the grinding mechanism to obtain zircon powder, zirconium corundum powder, and kaolin powder;

[0044] S4, the zircon powder, zirconium corundum powder and kaolin powder obtained by gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com