A kind of enameled wire tray installation method and its tray installation mechanism

A technology of installation mechanism and installation method, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems of easy toppling of trays, troubles, and inaccurate positioning of trays, etc., to achieve fully automated installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with specific embodiments.

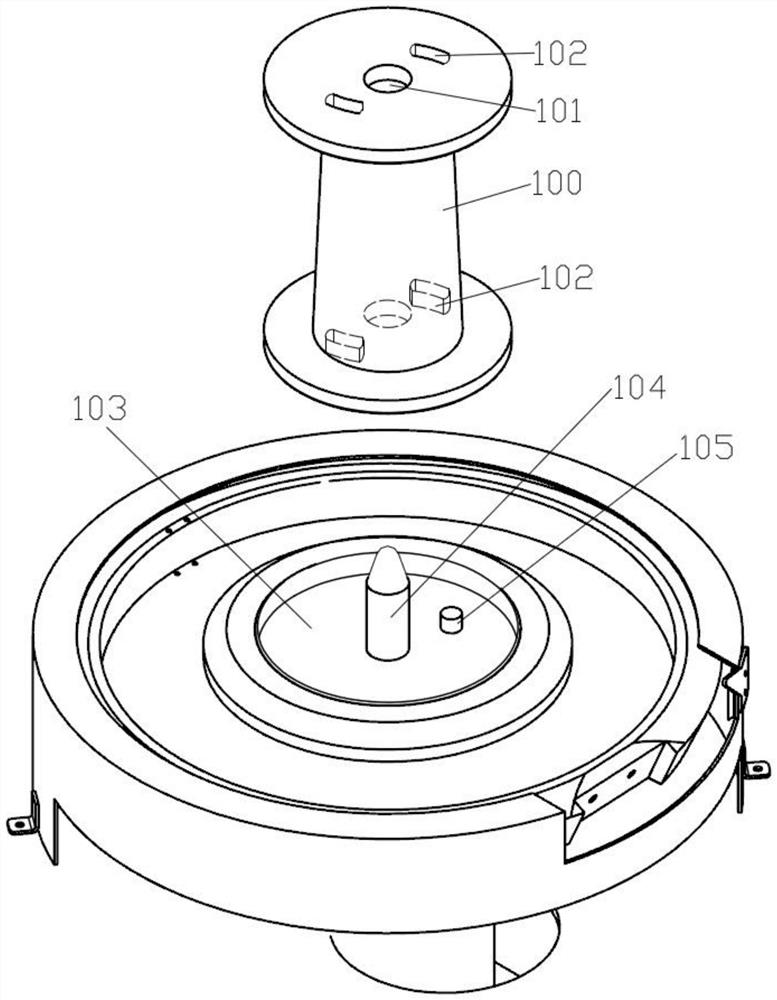

[0029] The center of the tray 100 has a central hole 101, and the bottom of the tray has a limit hole 102. After the tray 100 is placed in place, the enameled wire can be wound up in an orderly manner.

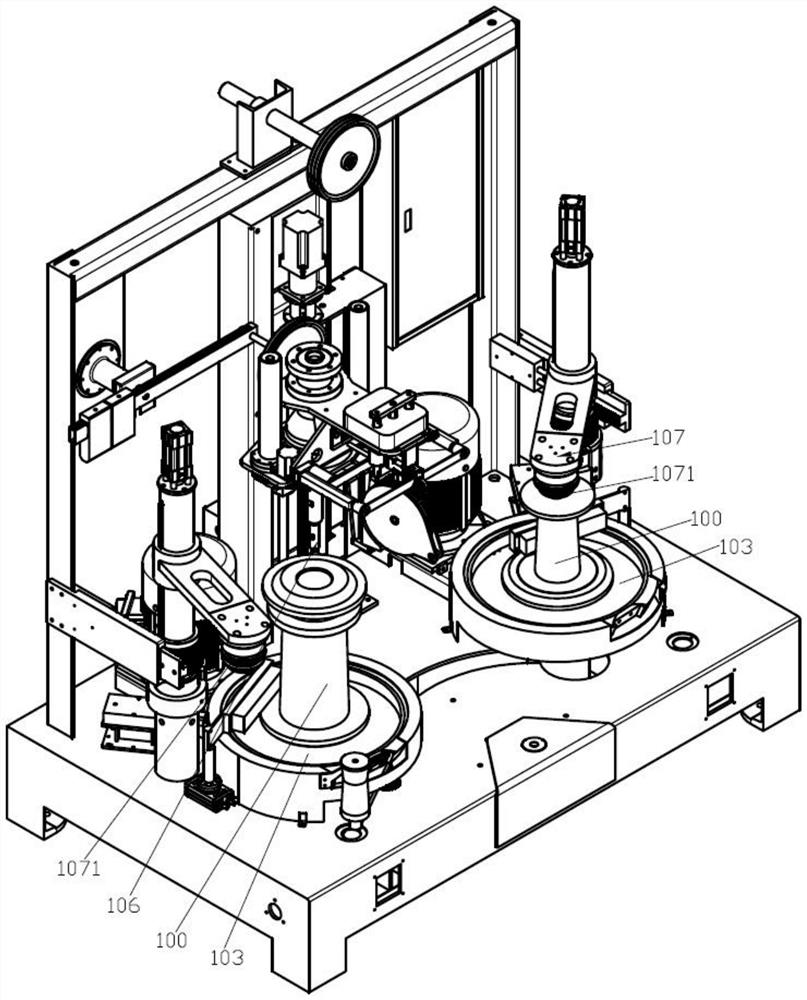

[0030] Such as figure 1 As shown, the present invention provides a method for installing an enameled wire tray. This method is used in the process of placing the empty tray 100 to ensure that the tray 100 is installed in place. The method includes the following steps:

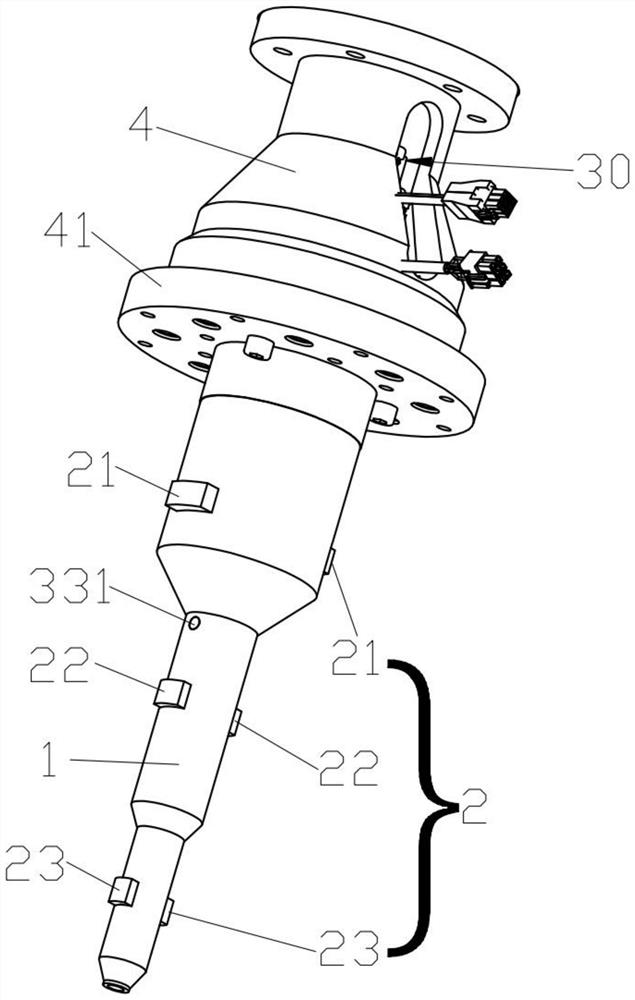

[0031] Step ①: lifting the tray 100: Insert the hanging tray device 106 into the central hole 101 of the tray 100 to lift the tray 100, and move the tray 100 to the top of the tray 103;

[0032] Step ②: put down the tray 100: place the tray 100 on the upper surface of the tray 103, release the tray 100 by the hanging tray device 106, and place the hanging tray device 106 in the central hole 101 of the tray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com