Large-size touch film production equipment

一种生产设备、触控膜的技术,应用在动力传送装置、印刷、转印材料等方向,能够解决生产成本高、价格昂贵、成品率不易控制等问题,达到保证精度和品质、避免断线的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

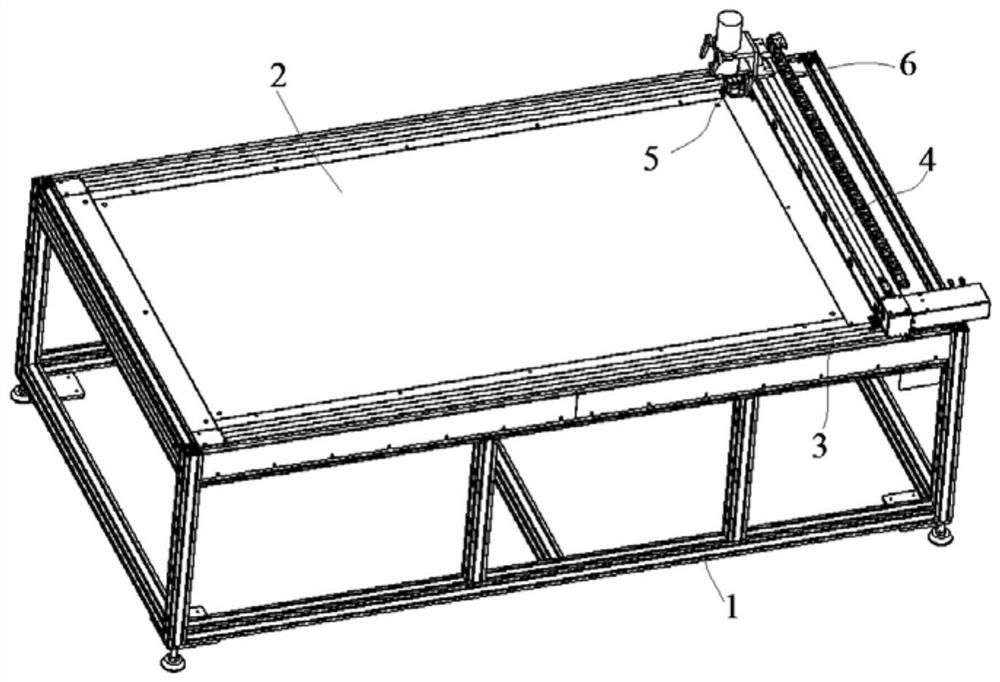

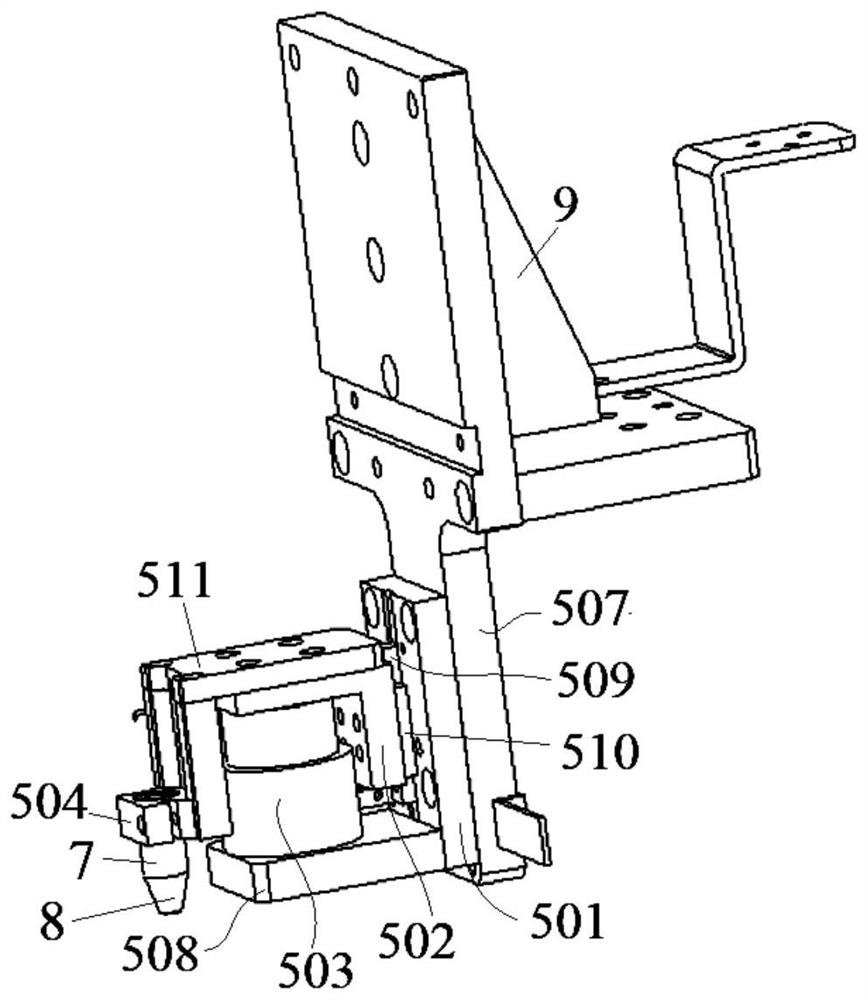

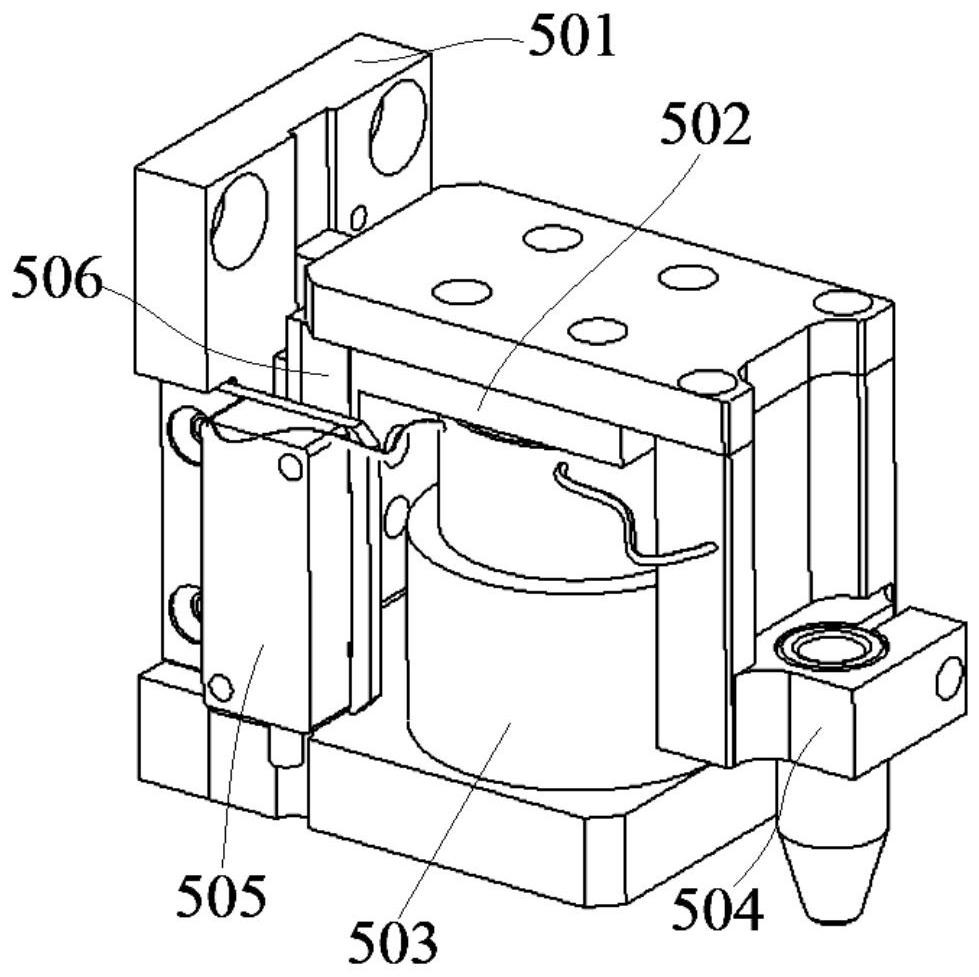

[0033] Embodiment 1: A production equipment for large-scale touch film, including a frame 1, a working panel 2, an X-axis driving mechanism 3, a Y-axis driving mechanism 4, and a Z-axis mechanism 5. The working panel 2 is horizontally installed on the machine On the frame 1, the X-axis drive mechanism 3 is installed on the frame 1, the Y-axis drive mechanism 4 is movably installed on the X-axis drive mechanism 3, and the Z-axis mechanism 5 is connected to the Y axis through a mounting plate 6. The shaft drive mechanism 4 is movably connected, and the Z-axis mechanism 5 has a testing state and a processing state. When the Z-axis mechanism 5 is in the testing state, a test head 7 is movably installed on the Z-axis mechanism 5. When the Z-axis mechanism 5. When it is in the processing state, the print nozzle 8 is movably installed on the Z-axis mechanism 5;

[0034] The print nozzle 8 is cylindrical with a central through hole 801. The lower end of the cylindrical nozzle is taper...

Embodiment 2

[0044] Embodiment 2: A production equipment for large-scale touch film, including a frame 1, a working panel 2, an X-axis driving mechanism 3, a Y-axis driving mechanism 4, and a Z-axis mechanism 5. The working panel 2 is horizontally installed on the machine On the frame 1, the X-axis drive mechanism 3 is installed on the frame 1, the Y-axis drive mechanism 4 is movably installed on the X-axis drive mechanism 3, and the Z-axis mechanism 5 is connected to the Y axis through a mounting plate 6. The shaft drive mechanism 4 is movably connected, and the Z-axis mechanism 5 has a testing state and a processing state. When the Z-axis mechanism 5 is in the testing state, a test head 7 is movably installed on the Z-axis mechanism 5. When the Z-axis mechanism 5. When it is in the processing state, the print nozzle 8 is movably installed on the Z-axis mechanism 5;

[0045] The print nozzle 8 is cylindrical with a central through hole 801. The lower end of the cylindrical nozzle is taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com