Paperboard laminating aluminum foil compounding process and compounding machine thereof

A composite machine and laminating technology, which is applied in lamination devices, lamination auxiliary operations, winding strips, etc., can solve problems such as energy waste, unfavorable environmental protection production, and large floor space, so as to ensure production efficiency and reduce Effect of heat loss and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

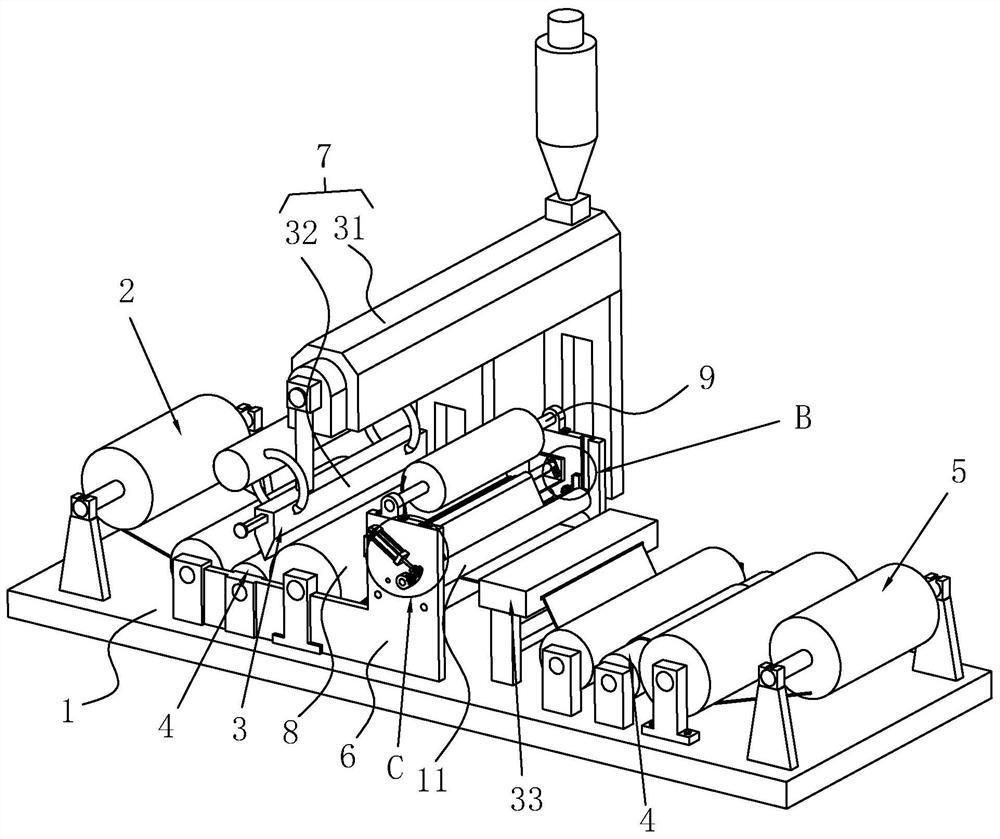

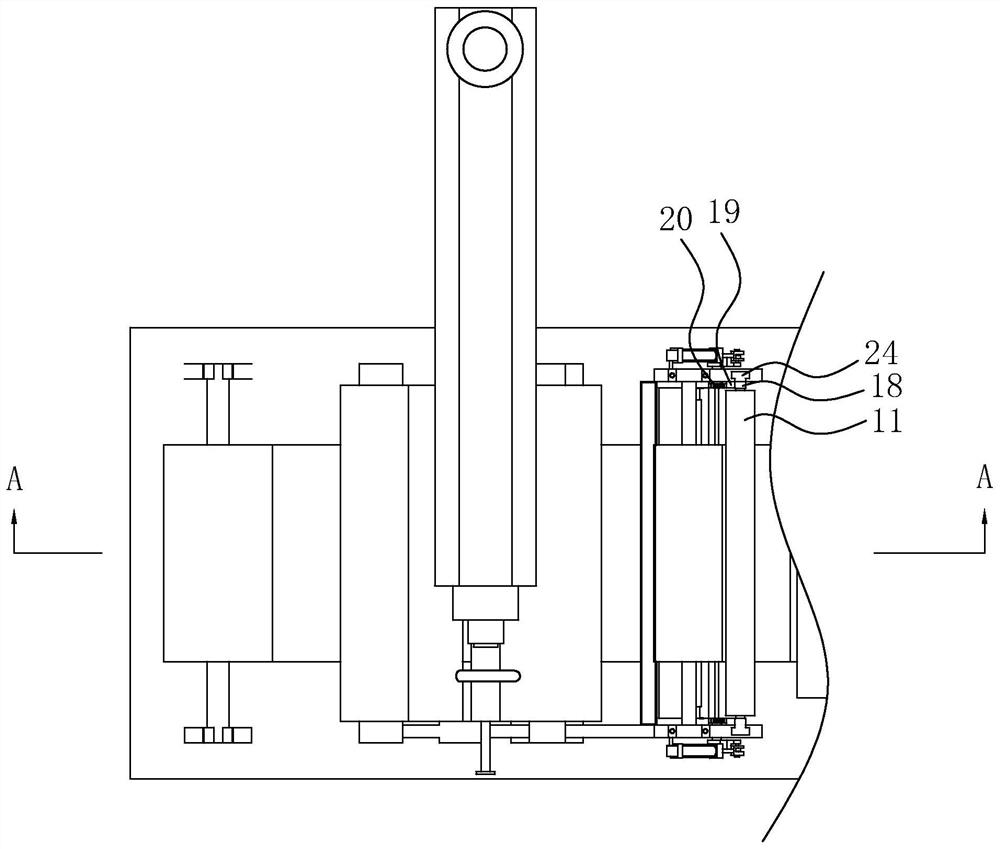

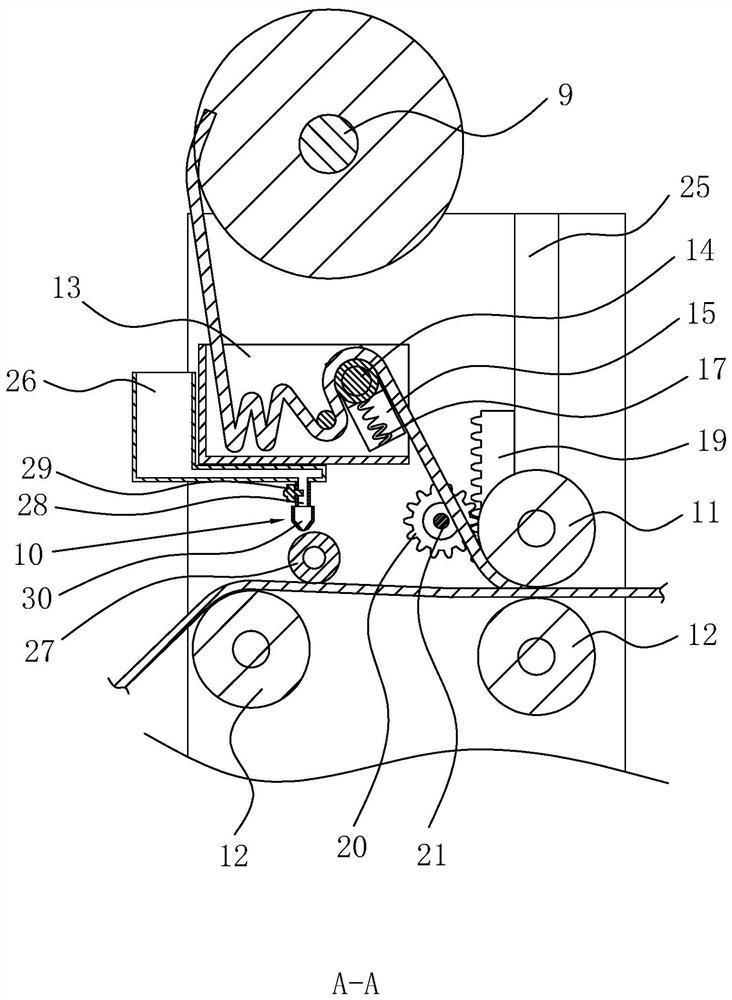

[0049] refer to figure 1 , is a cardboard laminating aluminum foil compound machine disclosed in the present invention, comprising a base 1, on which an unwinding part 2, a laminating part 3, a cooling part 4 and a rewinding part 5 are sequentially arranged, and the unwinding part 2 is used for For unwinding the cardboard base material into a roll, the rewinding part 5 is used for rewinding and laminating the laminated aluminum foil composite cardboard. The unwinding part 2 and the rewinding part 5 are common technical means in the field, and will not be repeated here. , the laminating part 3 includes a casing 6, a laminating mechanism 7 and a transfer roller group (not shown in the figure), and the laminating mechanism 7 includes an extruder 31 and a laminating film fixed at the discharge port of the extruder 31 The head 32 and the laminating head 32 are located directly above the cooling section 4, and the transfer roller group is also a common technical means in the art, an...

Embodiment 2

[0058] refer to Figure 6 , is a kind of cardboard-coated aluminum foil composite process disclosed by the present invention, based on the above-mentioned a kind of cardboard-coated aluminum foil composite machine, comprising the following steps:

[0059] S1. Unwinding, unwinding the rolled base material through the unwinding part 2 and pulling it into the coating part 3;

[0060] S2. Coating, the extruder 31 casts the molten PE through the coating head 32 onto the substrate to form a coating layer;

[0061] S3. Cooling and forming, passing the semi-finished coating base material obtained in step S2 through a plurality of cooling rollers 8 for slight cooling and shaping, to obtain a coating base material with certain viscosity;

[0062]S4. Applying glue, tensioning the laminating substrate obtained in step S3 with a certain viscosity through two support rollers 12, then opening the solenoid valve 29, and the glue in the glue box 26 is evenly coated by the glue roller 27 On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com