Press-fitting device for roller pin check ring for tripod ball

A press-fitting device and three-ball pin technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive labor intensity, large amount of assembly of the three-pin frame retaining ring, blockage, etc., and improve automation. degree and production efficiency, the effect of reducing labor intensity and cost of workers, and reducing the risk of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

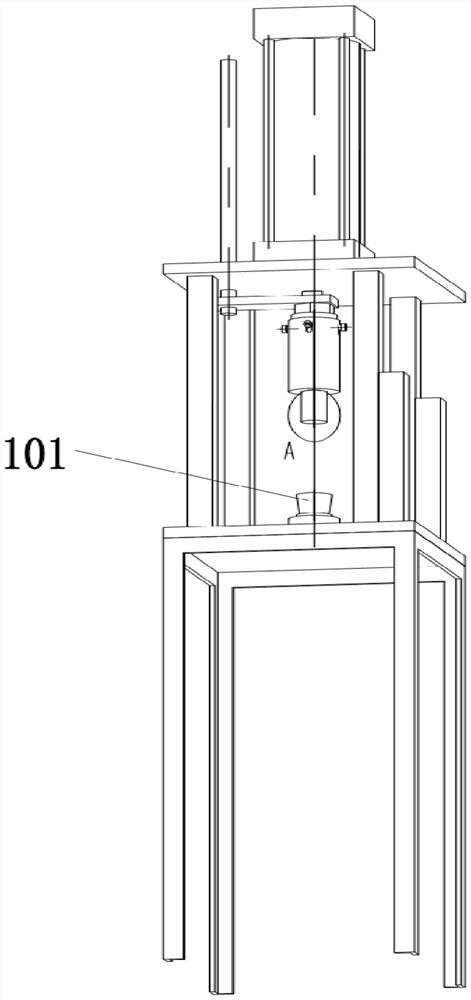

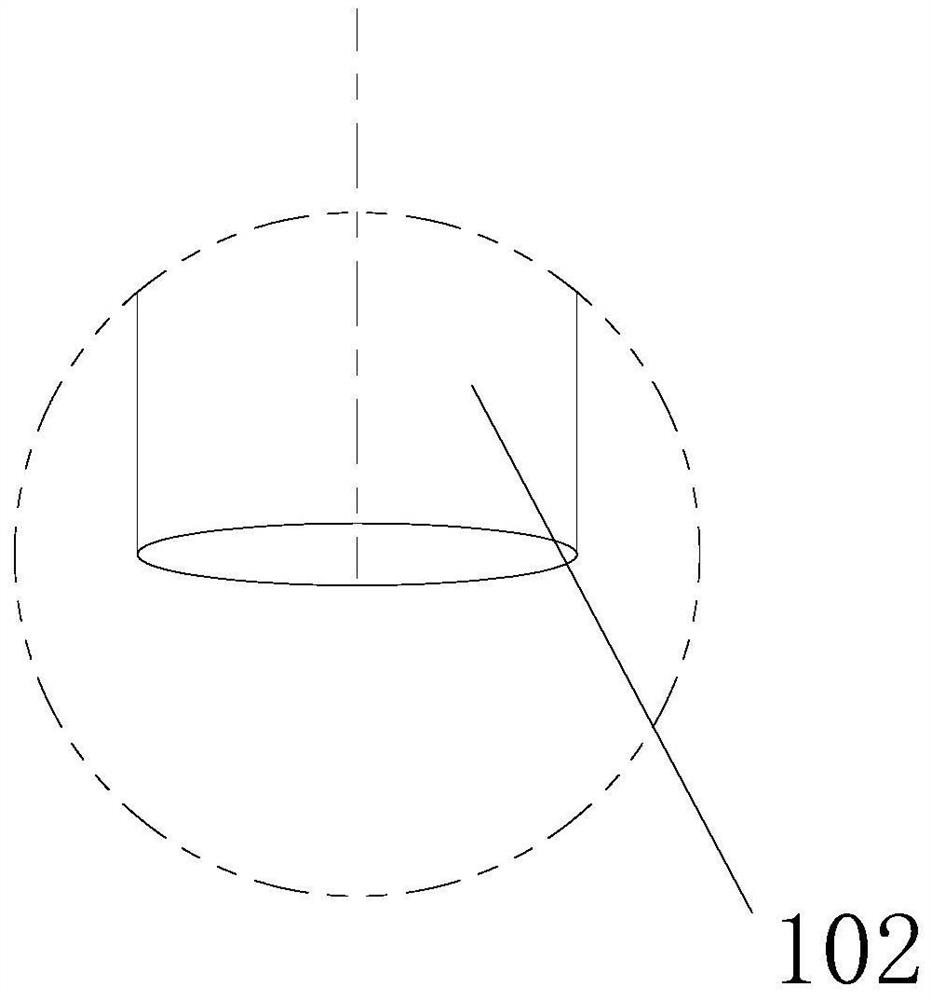

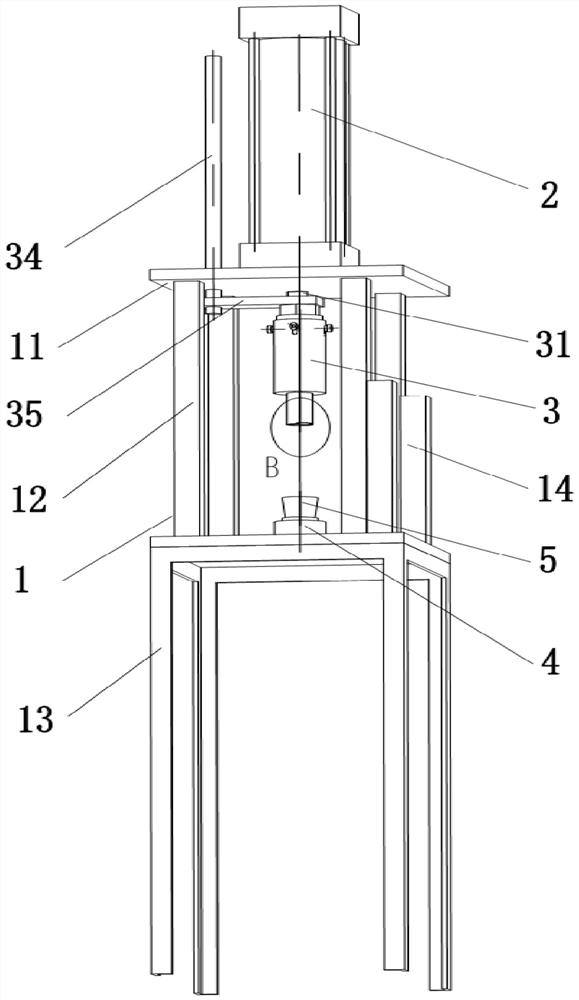

[0017] Embodiment: As shown in the accompanying drawings, this tripod pin retaining ring pressing device mainly includes a frame 1 composed of a frame top plate 11, a column 12, and a frame base 13, a driving device 2 and a transition shaft 31. Press-in device 3 composed of pressure sleeve 32, pressure head 33, guide column 34, anti-rotation plate 35, fixed base 4, retaining ring compression device 5, frame base 13 at the bottom of frame 1, frame base 13 top is column 12, and column 12 top connects frame top plate 11, and frame top plate 11 is provided with a through hole, and drive unit 2 is installed above frame top plate 11, and drive unit 2 selects cylinder for use. The lower end of the driving device 2 is connected through the through hole of the top plate 11 of the frame and drives the pressing device 3 to reciprocate up and down along its axis. One end of the transition shaft 31 of the pressing device 3 is connected with the piston rod of the driving device 2, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com