A mung bean seeding device

A sowing device and mung bean technology, applied in sowing seeders, planting methods, digging/covering ditches, etc., can solve the problems of cumbersome sowing steps, inconvenient arable land, and high cost, and achieve simple and convenient operation and reduce labor Effect of strength, utility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

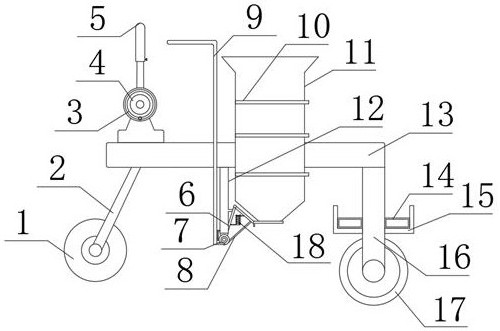

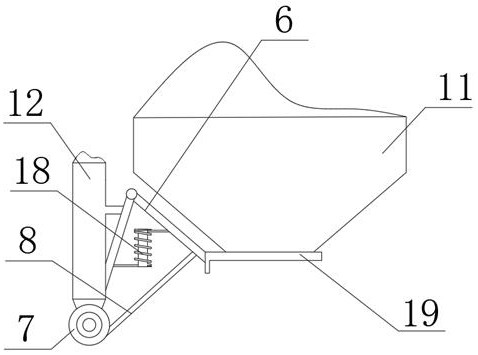

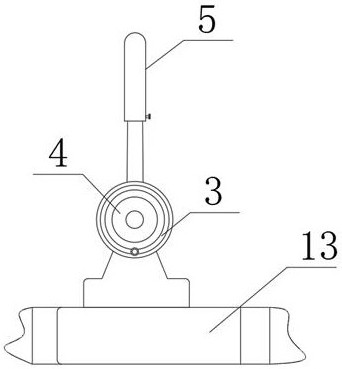

[0022] see Figure 1-5 , the present invention provides the following technical solutions: a mung bean planting device, comprising a support seat 13, a seeding box 11 is connected through the inside of the support seat 13, a fixing plate 19 is provided at the bottom end of the seeding box 11, and an integrally formed part is connected through the inside of the support seat 13 For the fixing rod 9, the outer surface of the support base 13 is welded with the integrally formed No. 3 support rod 12, and the end of one side of the No. 3 support rod 12 is connected with the No. 2 rotating shaft 7 through the support. The end of the outer surface of the fixing rod 9 is connected to the No. The outer surface of the No. 2 rotating shaft 7 is welded to each other, the outer surface of the No. 3 support rod 12 is connected with a hinge 6, and the inside of the hinge 6 is welded with a torsion spring 18, and the outer surface of the No. 2 rotating shaft 7 is welded with the No. 2 support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com