A kind of manufacturing method of artificial dielectric multi-layer ball lens

An artificial medium, multi-layer ball technology, applied in antennas, electrical components and other directions, can solve the problems of complex processing and heavy weight, and achieve the effects of stable performance, ultra-light weight and ultra-wide frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

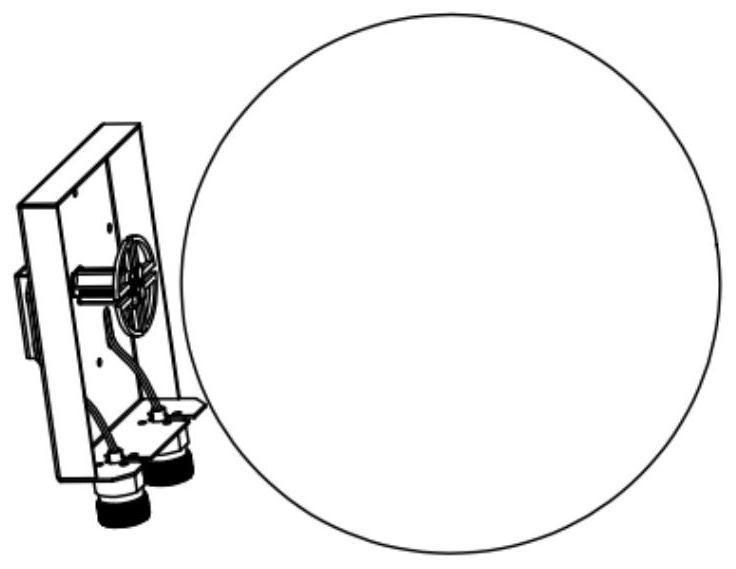

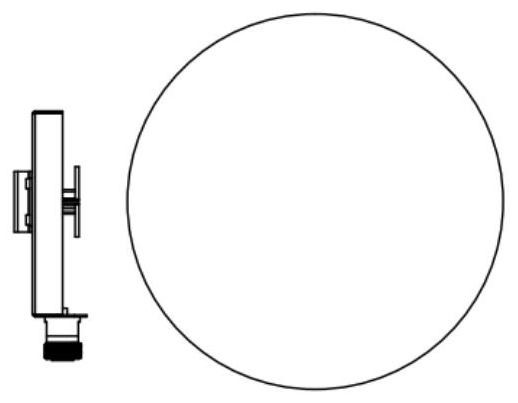

Image

Examples

Embodiment 1

[0070] The invention provides a novel method for producing a ball lens with an artificial dielectric layer, comprising the following steps:

[0071] S1: Make single-sided adhesive foam to form n pieces of substrates, wherein, 1≤n≤1000, the substrates are square;

[0072] S2: Spread the first base material in step S1 on the workbench, with the adhesive side facing up;

[0073] S3: Adhere the designed one or more high dielectric constant granular materials to the first substrate with the glue side facing up in step S2, and keep the glue side up to form the first particle layer;

[0074] S4: Unfold the second base material in step S1 with its adhesive side facing up, and adhere to the first particle layer formed in step S3;

[0075] S5: adhering one or more designed high dielectric constant granular materials to the second substrate with the glue side facing up in step S4, and keeping the glue side up to form a second particle layer;

[0076] S6: Comparing with step S4 to step ...

Embodiment 2

[0091] The invention provides a novel method for producing a ball lens with an artificial dielectric layer, comprising the following steps:

[0092] S1: Make single-sided adhesive foam to form n pieces of substrates, wherein, 1≤n≤1000, the substrates are square;

[0093] S2: Spread the first base material in step S1 on the workbench, with the adhesive side facing up;

[0094] S3: Adhere the designed one or more high dielectric constant granular materials to the first substrate with the glue side facing up in step S2, and keep the glue side up to form the first particle layer;

[0095] S4: Unfold the second base material in step S1 with its adhesive side facing up, and adhere to the first particle layer formed in step S3;

[0096] S5: adhering one or more designed high dielectric constant granular materials to the second substrate with the glue side facing up in step S4, and keeping the glue side up to form a second particle layer;

[0097] S6: Comparing with step S4 to step ...

Embodiment 3

[0115] The invention provides a novel method for producing a ball lens with an artificial dielectric layer, comprising the following steps:

[0116] S1: Make single-sided adhesive foam to form n pieces of substrates, wherein, 1≤n≤1000, the substrates are square;

[0117] S2: Spread the first base material in step S1 on the workbench, with the adhesive side facing up;

[0118] S3: Adhere the designed one or more high dielectric constant granular materials to the first substrate with the glue side facing up in step S2, and keep the glue side up to form the first particle layer;

[0119] S4: Unfold the second base material in step S1 with its adhesive side facing up, and adhere to the first particle layer formed in step S3;

[0120] S5: adhering one or more designed high dielectric constant granular materials to the second substrate with the glue side facing up in step S4, and keeping the glue side up to form a second particle layer;

[0121] S6: Comparing with step S4 to step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com