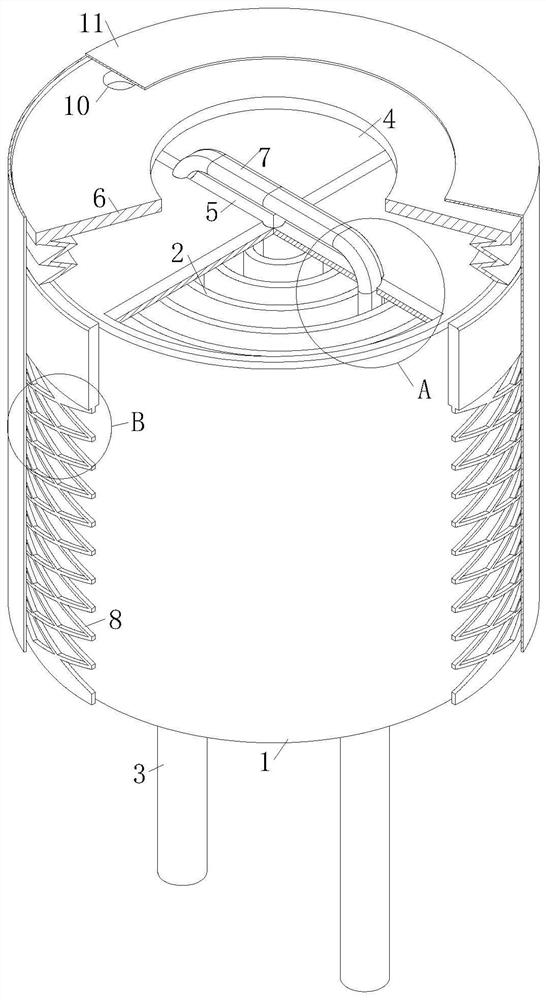

An aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and aluminum shells, applied in the electronic field, can solve the problems of polluting the electronic components of the capacitor circuit board, bursting of the top cover of the capacitor, and no protection of the capacitor, so as to ensure safety, avoid electrolyte splashing, and reduce radial deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

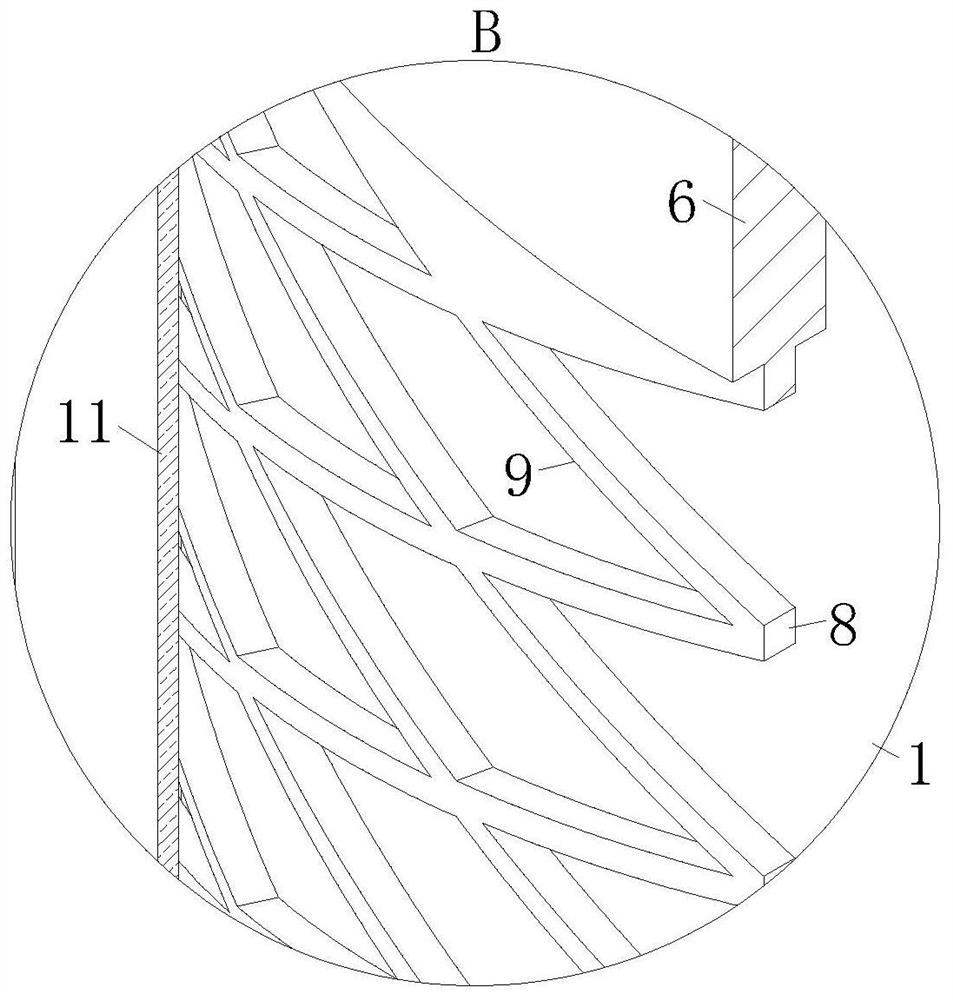

[0031] As an embodiment of the present invention, the gap between the pre-broken groove 5 and the telescopic sleeve 6 is filled with thermally conductive silicone grease; the gap between the pre-broken groove 5 and the telescopic sleeve 6 is filled with thermally conductive silicone grease Eliminate the gap between the top cover 4 and the telescopic sleeve 6, increase the heat transfer efficiency of the top cover 4, further increase the heat dissipation efficiency of the capacitor, and reduce the damage caused by the high temperature of the capacitor.

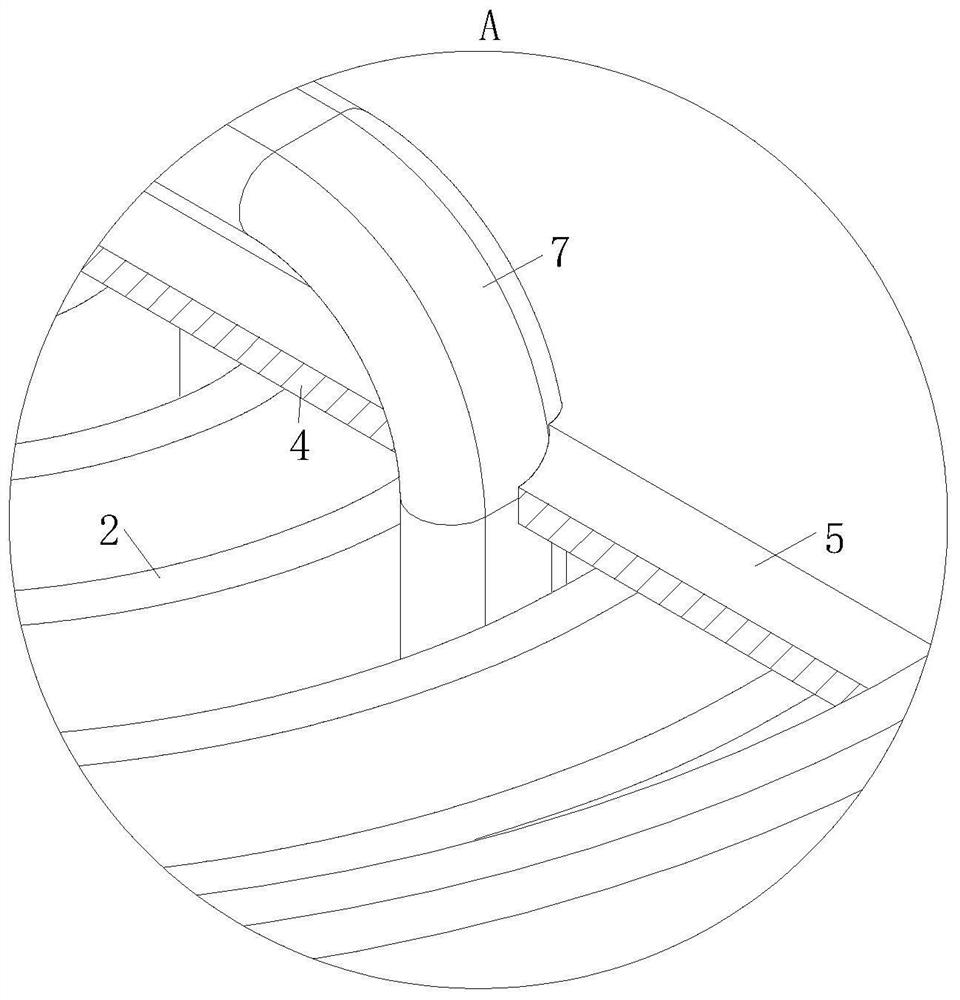

[0032] As an embodiment of the present invention, a group of heat pipes 7 are arranged in the winding layer 2, and the heat pipes 7 are arranged in an inverted U shape; the top of the heat pipes 7 is attached to the top cover 4; the heat dissipation of the capacitor is increased through the heat pipes 7 speed; quickly absorb the heat generated between the winding layers 2 through the heat pipe 7, avoiding the time for the heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com