Cement solidification system and method for radioactive waste treatment and application

A radioactive waste and cement solidification technology, applied in radioactive purification, nuclear engineering, etc., can solve problems such as complexity, high equipment costs, and poor applicability, and achieve the effect of reducing disposal costs, reducing investment costs, and simple and reliable operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

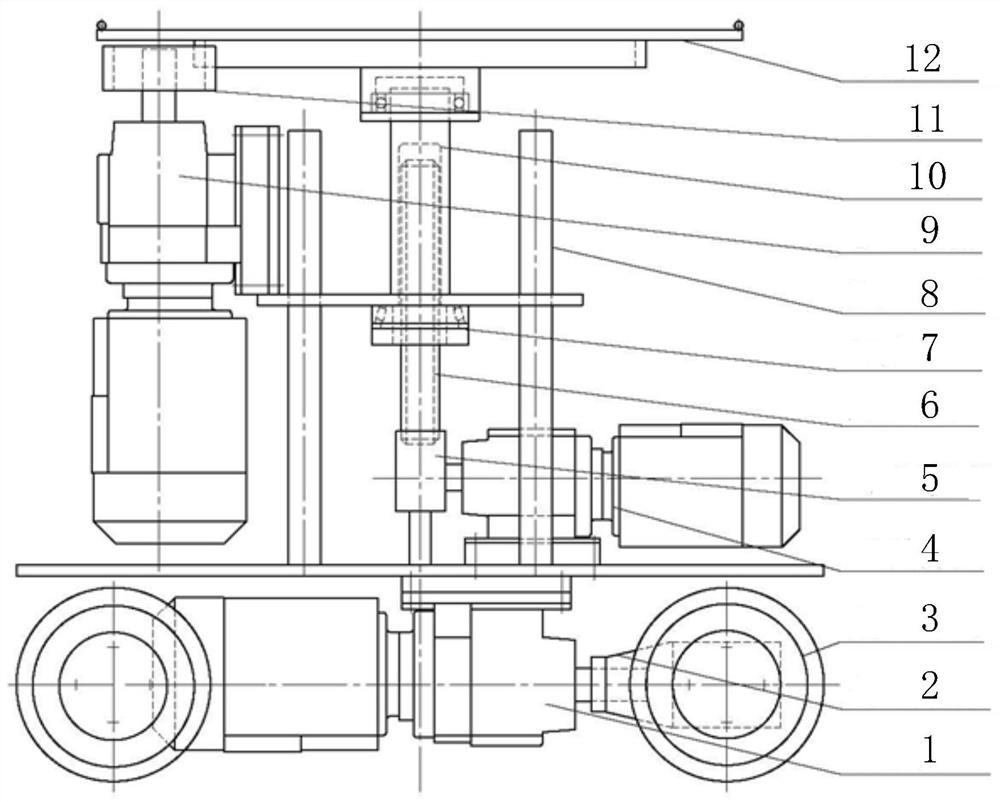

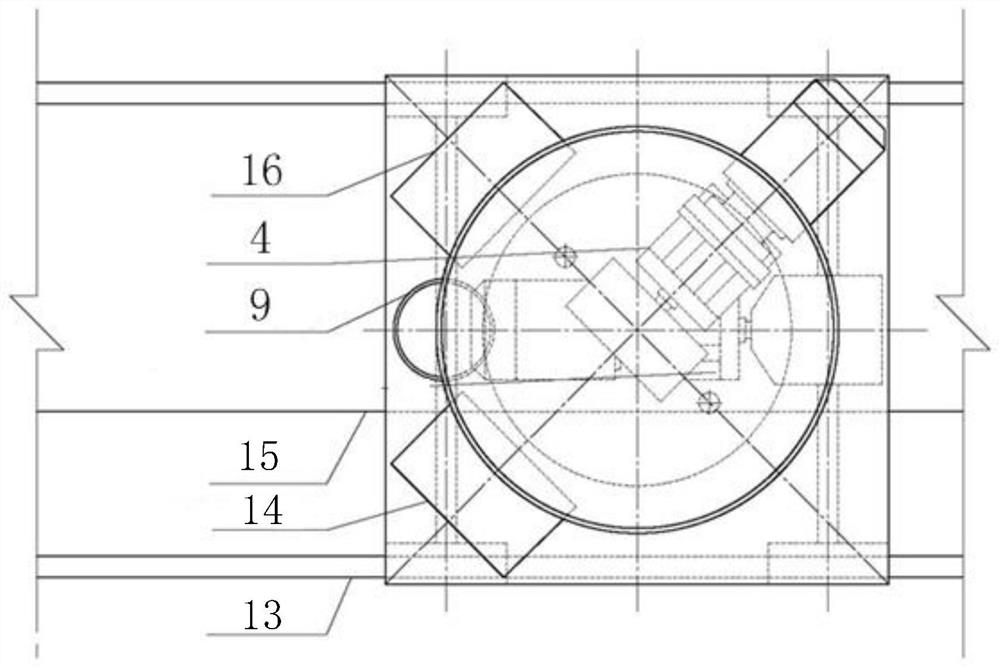

[0057] Such as figure 1 , figure 2 As shown, a cement curing system for radioactive waste treatment includes a three-axis rail car, a track 13, a scale detection system, and a wireless control system 14;

[0058] The three-axis rail car includes a horizontal movement system, a vertical lifting system, and a rotation system. The horizontal movement system includes a motion reducer 1, a transmission assembly 2 and a wheel train 3. The power output shaft of the motion reducer 1 passes through the transmission The assembly 2 is connected to the wheel system 3;

[0059] The vertical lifting system includes a lifting reducer 4, a turbine reducer 5, a lead screw 6 and a nut 7. The lifting reducer 4 is arranged on the top of the motion reducer 1, and the power output shaft of the lifting reducer 4 passes The turbine reducer 5 is connected with the screw 6, and the nut 7 is sleeved on the screw 6;

[0060] The rotating system includes a rotating reducer 9, an orientation assembly 10, a gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com