Early warning method and early warning system for preventing SO2 standard-exceeding emission of desulfurized flue gas and application of early warning method and early warning system

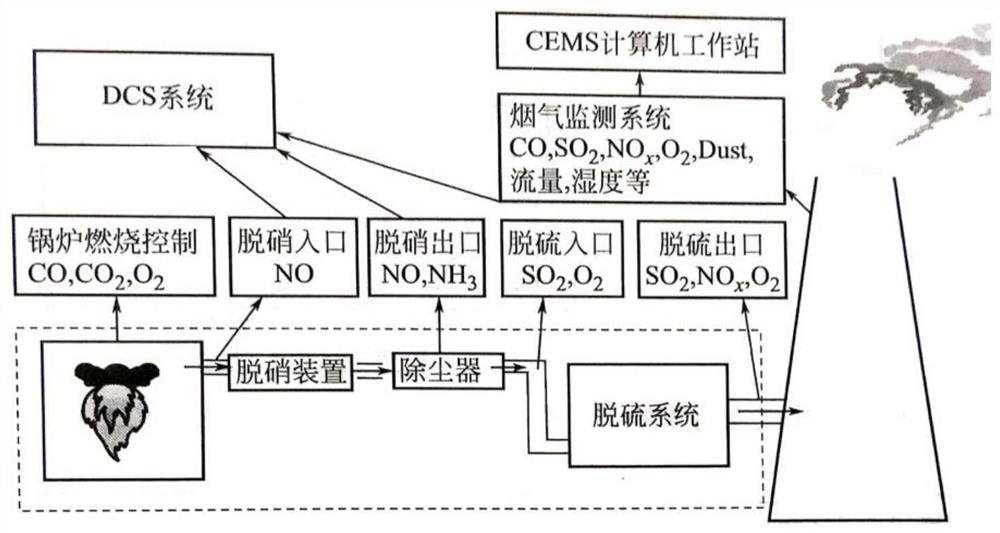

An early warning system and SO2 technology, applied in the field of flue gas desulfurization, can solve the problems of lag in the operation and adjustment of the desulfurization system, and achieve the effects of improving the operation economy, solving the lag, and preventing excessive emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method to prevent desulfurization flue gas SO 2 The early warning method of excessive discharge, the steps are as follows:

[0036] Step S1: Detect the coal supply in real time and obtain the current coal supply

[0037] Specifically, the conventional coal feed detection device is used to detect the coal feed of the boiler in real time, and the first time t 1 The coal supply data is the current coal supply.

[0038] Step S2: Obtain the previous coal supply

[0039] The current coal supply is delayed by the preset time t to form the previous moment t 0 The amount of coal supplied is the previous coal supply; among them, t 0 = t 1 -t.

[0040]In this embodiment, the preset time t is set to 10 seconds; in other embodiments, an appropriate preset time t may be set according to actual conditions.

[0041] Step S3: Obtain the difference of the previous coal supply before the current coal supply exceeds the preset time

[0042] Specifically, ...

Embodiment 2

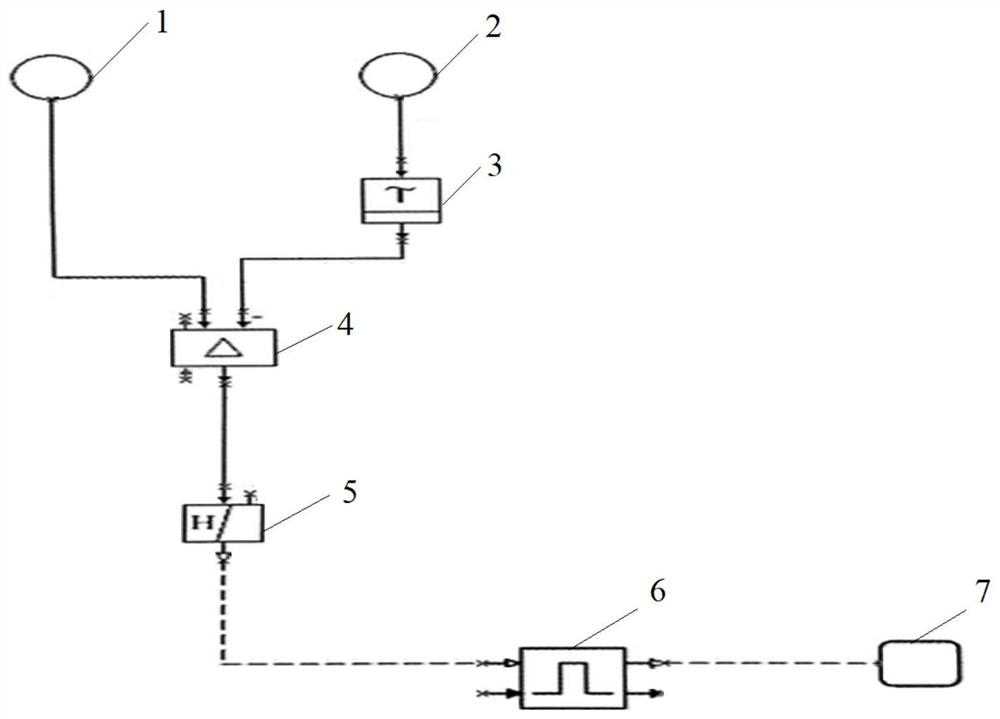

[0048] Such as figure 2 As shown, this embodiment provides a method to prevent desulfurization flue gas SO 2 The early warning system for excessive emissions includes: a real-time detection module for coal supply, a data processing module and an alarm module 6. The real-time detection module for coal supply detects the coal supply in real time and sends the acquired coal supply signal to the data processing module. The module obtains the difference of the previous coal supply before the current coal supply exceeds the preset time, and sends an early warning signal to the alarm module 6 when the difference is greater than the preset value, and the alarm module 6 gives an alarm when receiving the early warning signal.

[0049] The specific structures of the above modules are not strictly limited, and appropriate structures can be selected according to their respective functions.

[0050] In this embodiment, two coal supply real-time detection modules are set, that is, the firs...

Embodiment 3

[0057] This embodiment is an application example of the early warning method of embodiment 1 and the early warning system of embodiment 2.

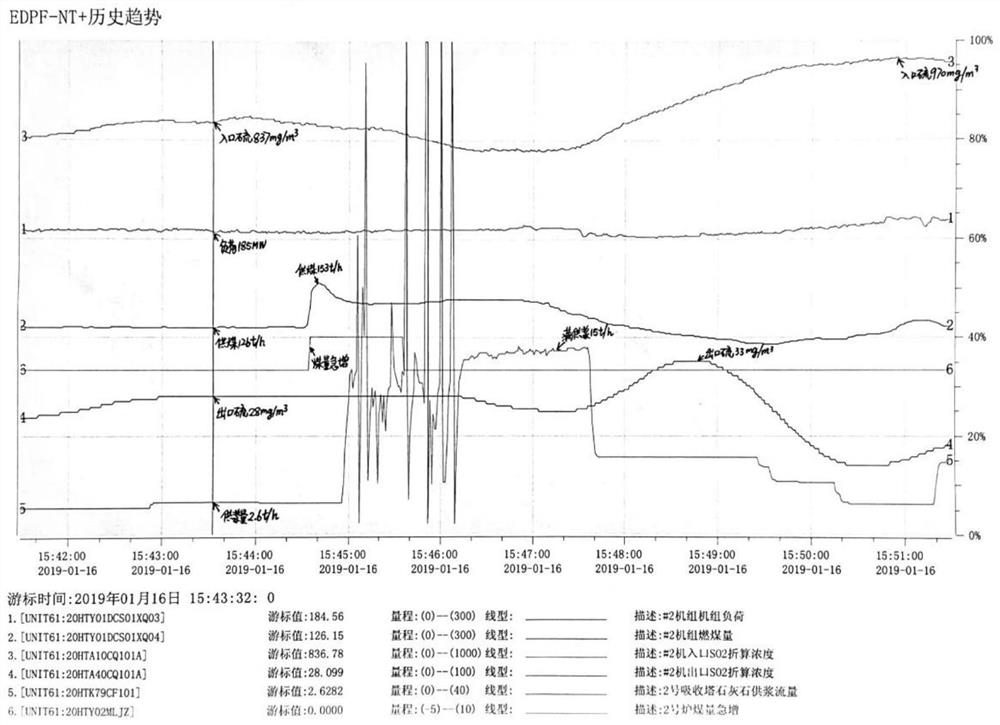

[0058] On January 16, 2019, at 15:43:30, the coal supply was 126t / h, the slurry supply was 2.6t / h, and the SO 2 The concentration is 28mg / Nm 3 At 15:44:40, the amount of coal burned increased sharply to 153t / h, which triggered an early warning of a sharp increase in coal amount. The operator immediately increased the amount of slurry supplied to 15t / h, and exported SO 4 minutes later. 2 The concentration rose to a peak of 33mg / Nm 3 , there is no excessive discharge; the monitoring results are as in 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com