Dual-valve-core multiported valve with horizontal layout

A dual-spool, multi-port valve technology, applied in the field of multi-port valves, can solve the problems of insufficiency, the increase in the number of medium inlet pipes, and the difficulty of medium inlet pipes, so as to achieve flexible and fast rotation metering, and reduce the plane occupied space. , the effect of high metering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

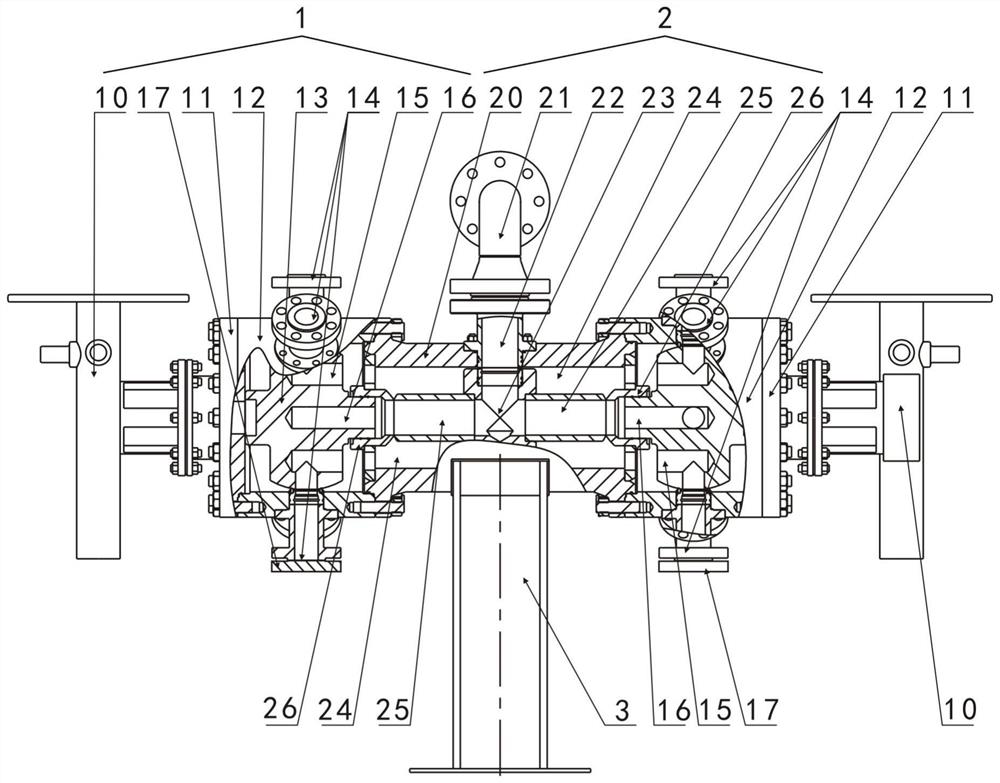

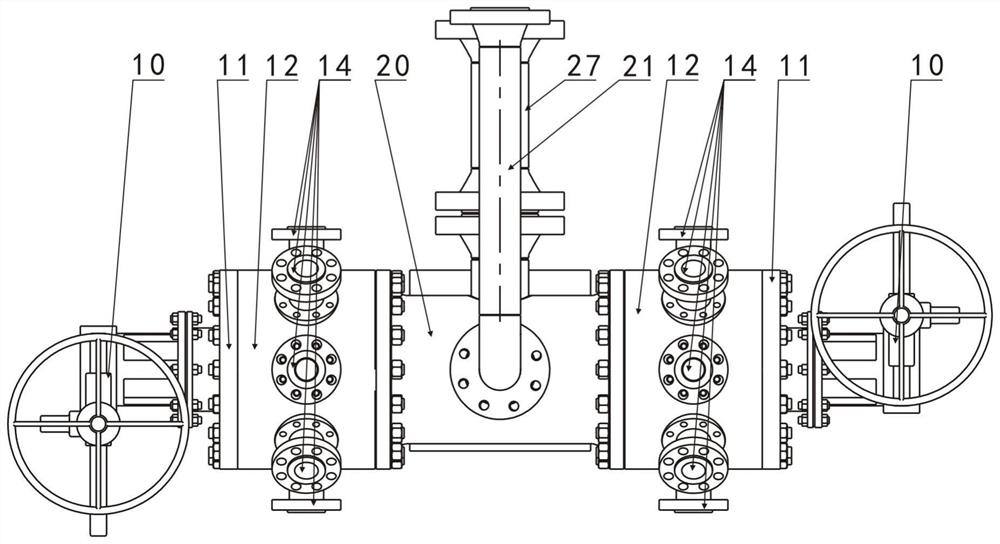

[0022] like figure 1 and figure 2 As shown, a double-spool multi-way valve with a horizontal layout includes a circular tube-shaped valve body 12 and a connecting pipe 20. The valve body 12 is provided with a valve core 13, and the peripheral wall of the valve body 12 is provided with eight peripheral valves. Into the distributed medium into the pipe 14, the central position of the spool 13 is provided with a spool axial central hole 16, and eight spool axial peripheral holes 15 are distributed around the spool axial central hole 16, and the spool axial The central hole 16 can communicate with any one of the medium inlet pipes 14 correspondingly, and when communicating, the eight valve core axial peripheral holes 15 communicate with the remaining seven medium inlet pipes 14 one by one; there are two valve bodies 12 with the same structure, The axial direction of the connecting pipe 20 and the axial direction of the valve body 12 are both horizontal. The peripheral wall of th...

Embodiment 2

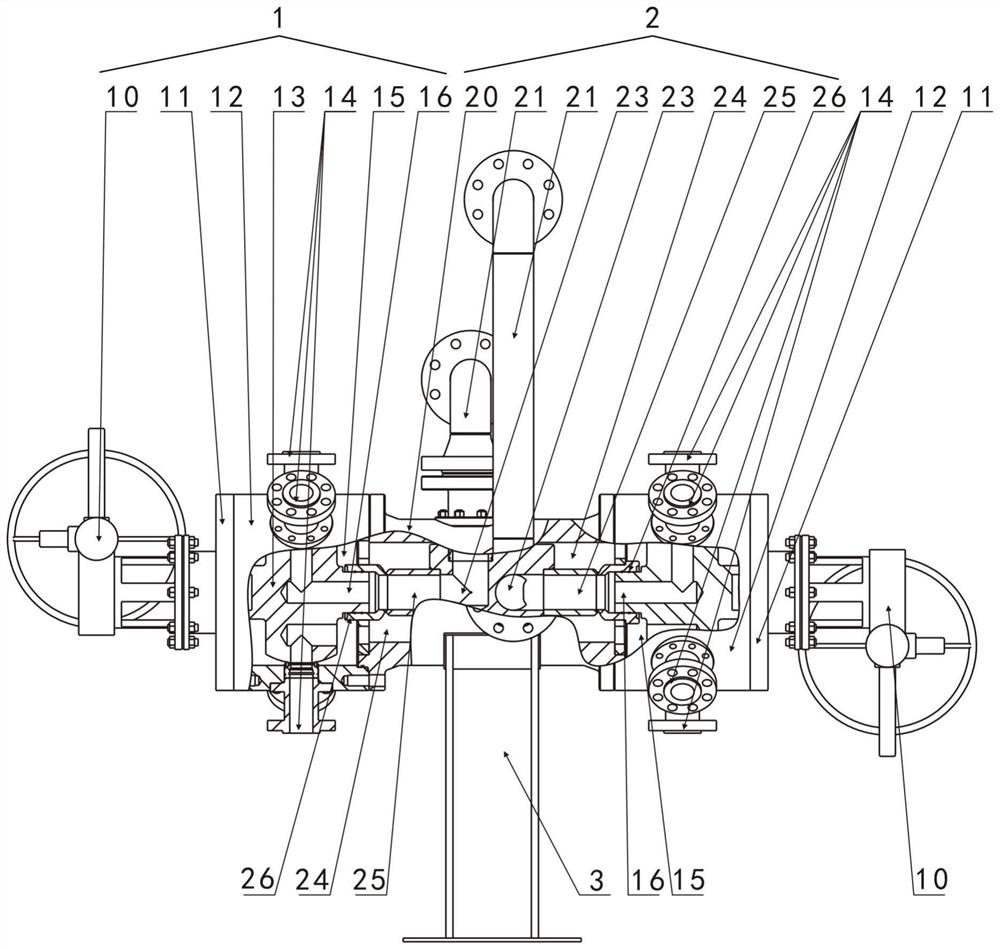

[0028] like image 3 and Figure 4 As shown, a double-spool multi-way valve with a horizontal layout includes a circular tube-shaped valve body 12 and a connecting pipe 20. The valve body 12 is provided with a valve core 13, and the peripheral wall of the valve body 12 is provided with eight peripheral valves. Into the distributed medium into the pipe 14, the central position of the spool 13 is provided with a spool axial central hole 16, and eight spool axial peripheral holes 15 are distributed around the spool axial central hole 16, and the spool axial The central hole 16 can communicate with any one of the medium inlet pipes 14 correspondingly, and when communicating, the eight valve core axial peripheral holes 15 communicate with the remaining seven medium inlet pipes 14 one by one; there are two valve bodies 12 with the same structure, The axial direction of the connecting pipe 20 and the axial direction of the valve body 12 are both horizontal. The peripheral wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com