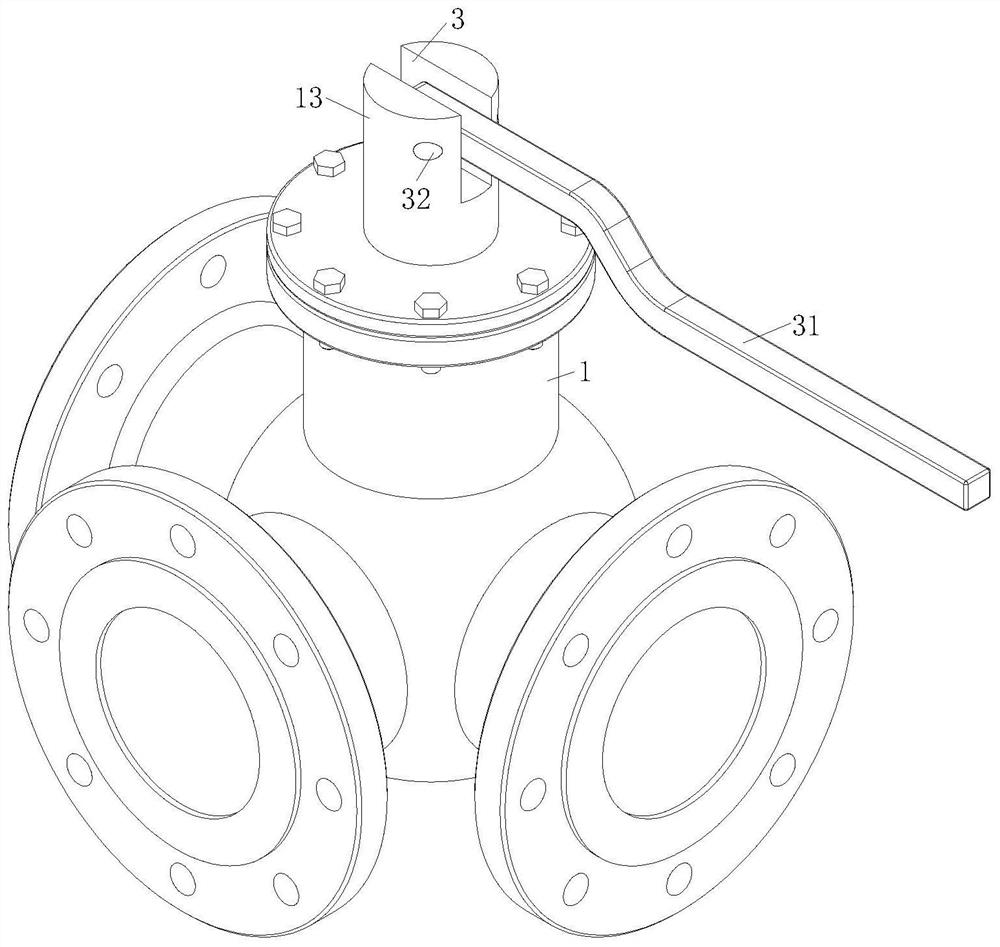

A three-way ball valve

A technology for three-way ball valves and ball valves, which is applied to multi-way valves, valve devices, cocks including cut-off devices, etc., can solve the problems of affecting the opening and closing efficiency of valves, difficulty in opening and closing valves, and physical exertion, etc., and achieve reduction Effects of pressure, friction reduction, and increased lubrication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

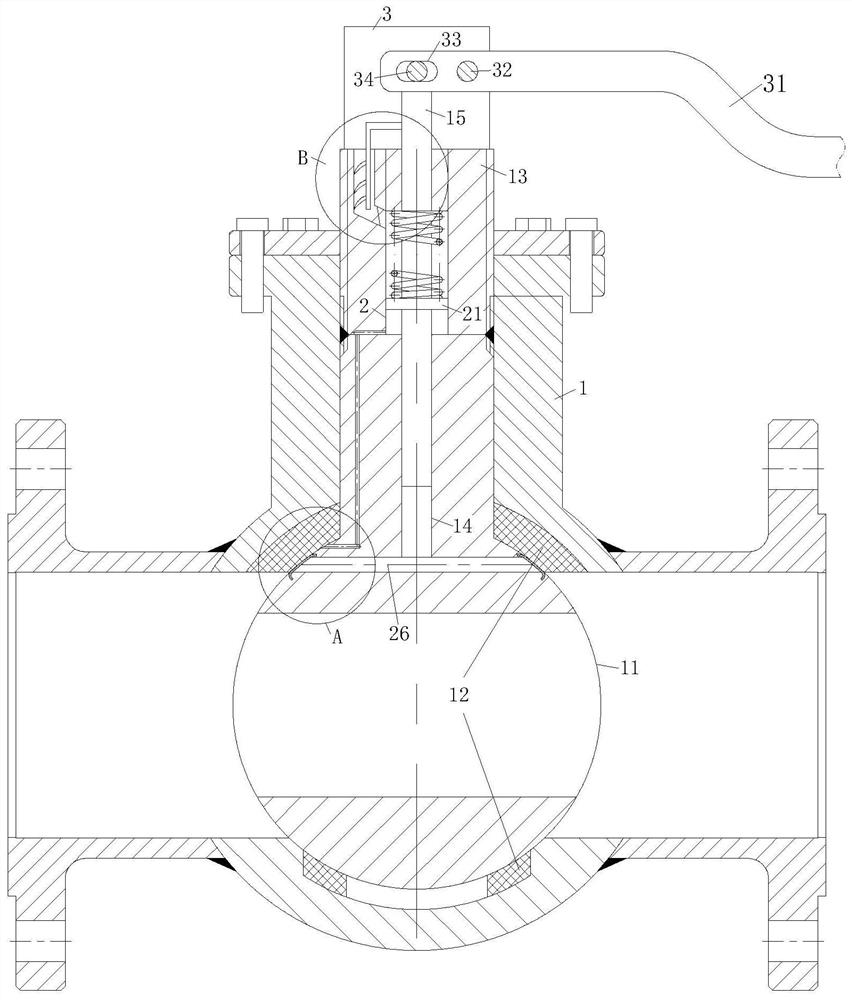

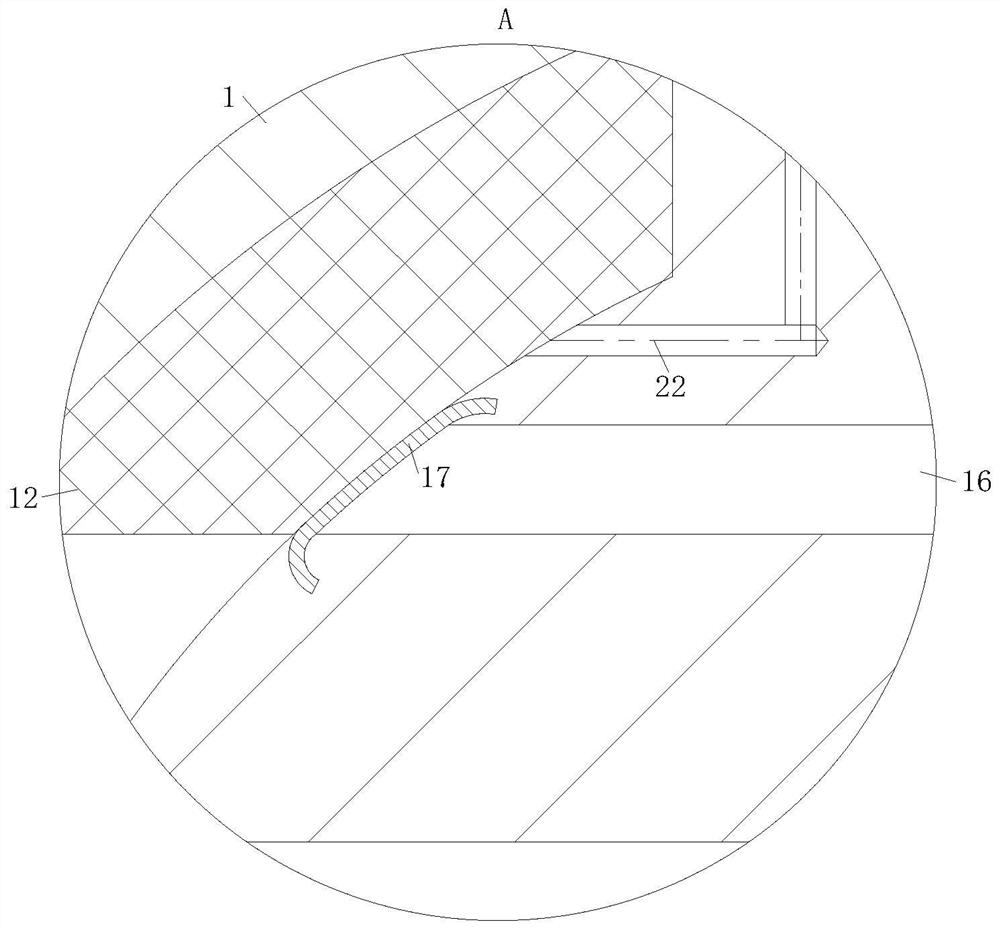

[0025] As an embodiment of the present invention, lubricating grease is housed in the chute 2, and a lubricating hole 22 is provided on one side of the top of the chute 2, and the bottom end of the lubricating hole 22 communicates with the valve seat 12; Press the grease to increase the lubrication between the valve seat 12 and the valve ball 11, and further increase the opening efficiency of the ball valve; when the handle 31 is pressed to drive the spool 15 to slide upward in the No. 1 hole 14, the spool 15 drives the limit ring 21 slides upward, and then squeezes the lubricating grease in the chute 2, so that the lubricating grease flows along the lubricating hole 22 to between the valve ball 11 and the valve seat 12, and then performs good lubrication on the outer periphery of the valve ball 11, reducing the valve ball 11 The friction between the ball valve and the valve seat 12 further increases the opening efficiency of the ball valve. At the same time, due to the high vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com