Main drive sealing system and method of shield machine self-adapting to soil bin pressure changes

A technology of soil bunker pressure and sealing system, which is used in earth-moving drilling, mining equipment, mining equipment, etc., can solve the problems of increasing construction cost, aging and wear, and deformation of the sealing body, so as to control the oil consumption and ensure the performance. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

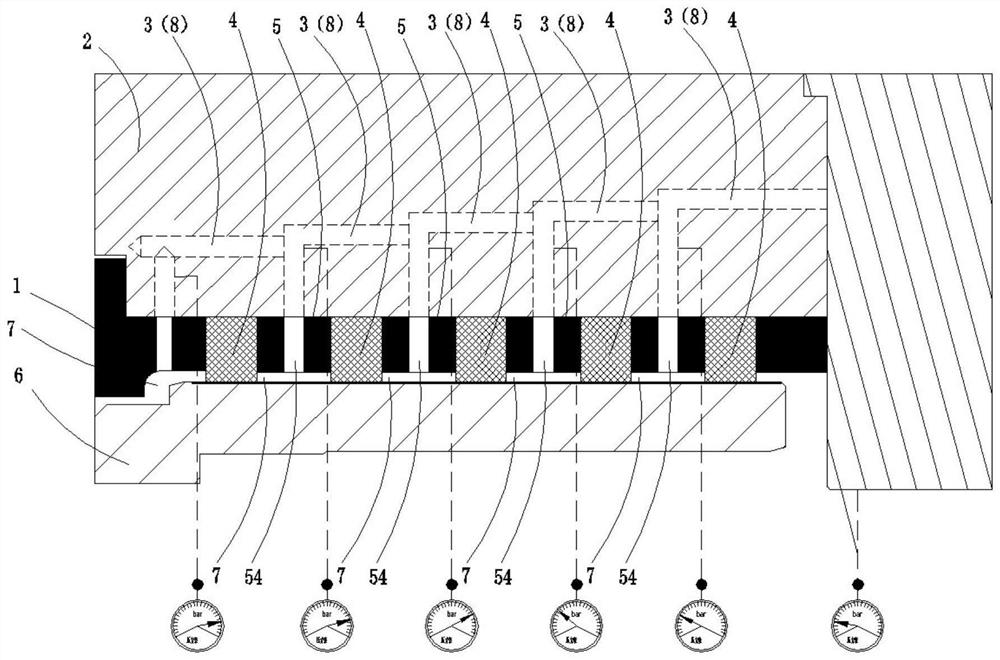

[0033] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

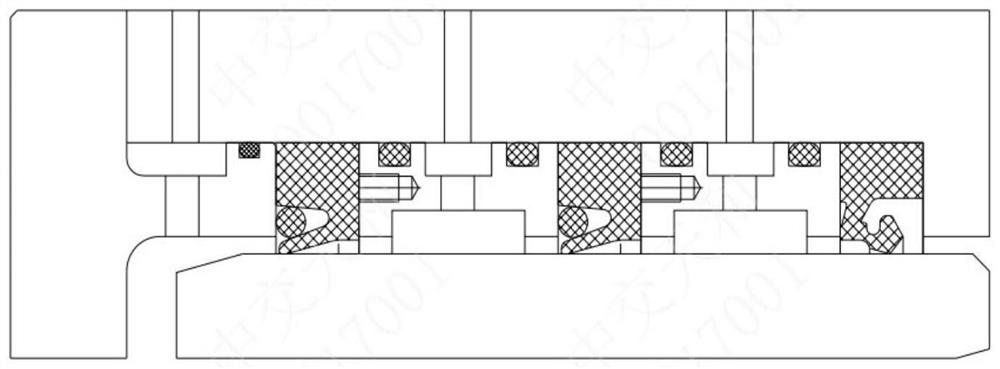

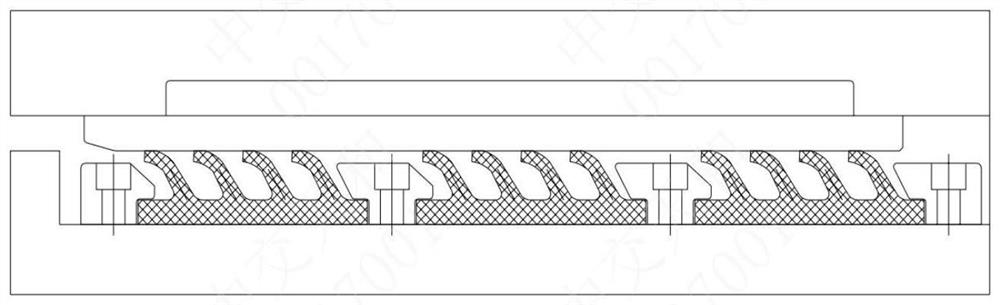

[0034] Such as image 3 As shown, the main drive sealing system of the shield machine adaptive to the pressure change of the soil bin includes a fluid channel box 2, a friction ring 6, a sealing medium 3, a sealing spacer ring 5, a plurality of sealing rings 4, a port labyrinth ring 1, and a pressure control module . Fluid channel box 2, friction ring 6, sealing spacer ring 5 and multiple sealing rings 4 are coaxially arranged, fluid channel box 2 is set on friction ring 6 and forms an annular gap with friction ring 6, port labyrinth ring 1 and a plurality of sealing rings 4 divide the gap into multiple annular pressure chambers 7, and a plurality of injection channels 8 for injecting sealing medium 3 into each pressure chamber 7 are opened in the fluid passage box 2, and the sealing medium 3 is filled in the injection Inside the channel 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com