Omnibearing pressure relief method for thick coal seam working face rock burst danger roadway

A technology of ground pressure and working face, which is used in tunnels, earthwork drilling, mining equipment, etc., can solve the different degrees of pressure relief of the surrounding rock of the roadway, and cannot ensure the coordination and integrity of the pressure relief effect of the surrounding rock of the roadway, etc. To achieve the effect of maintaining stability and safety, ensuring coordination and integrity, and preventing coal protruding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

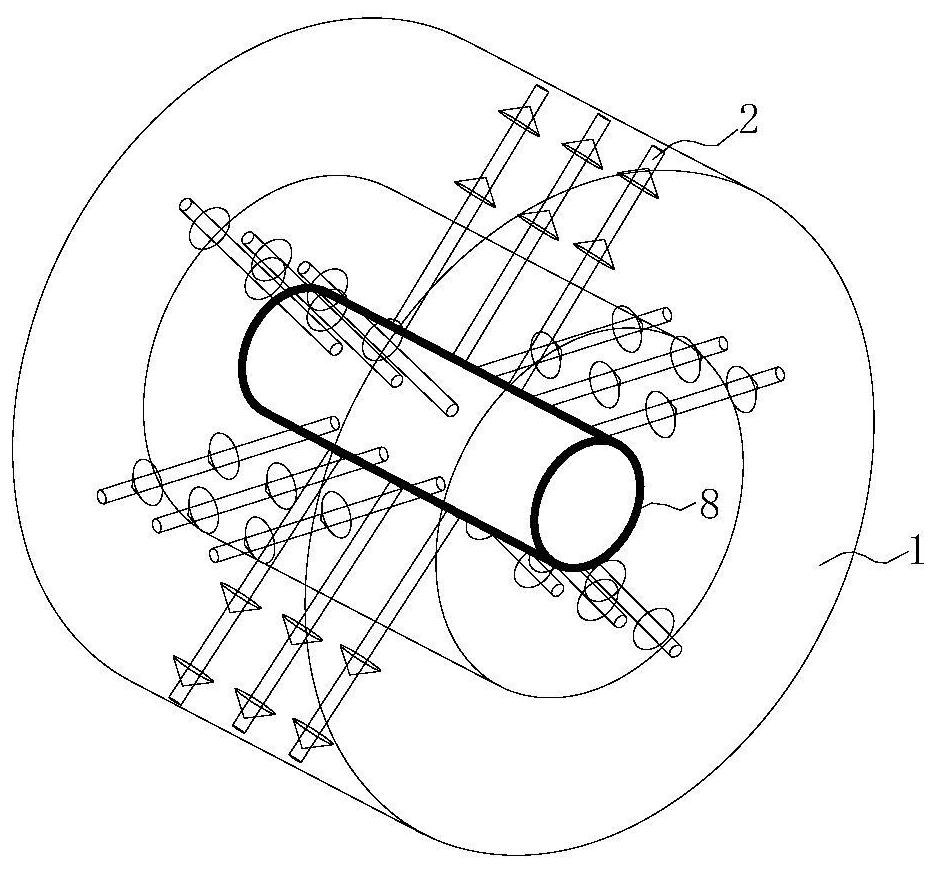

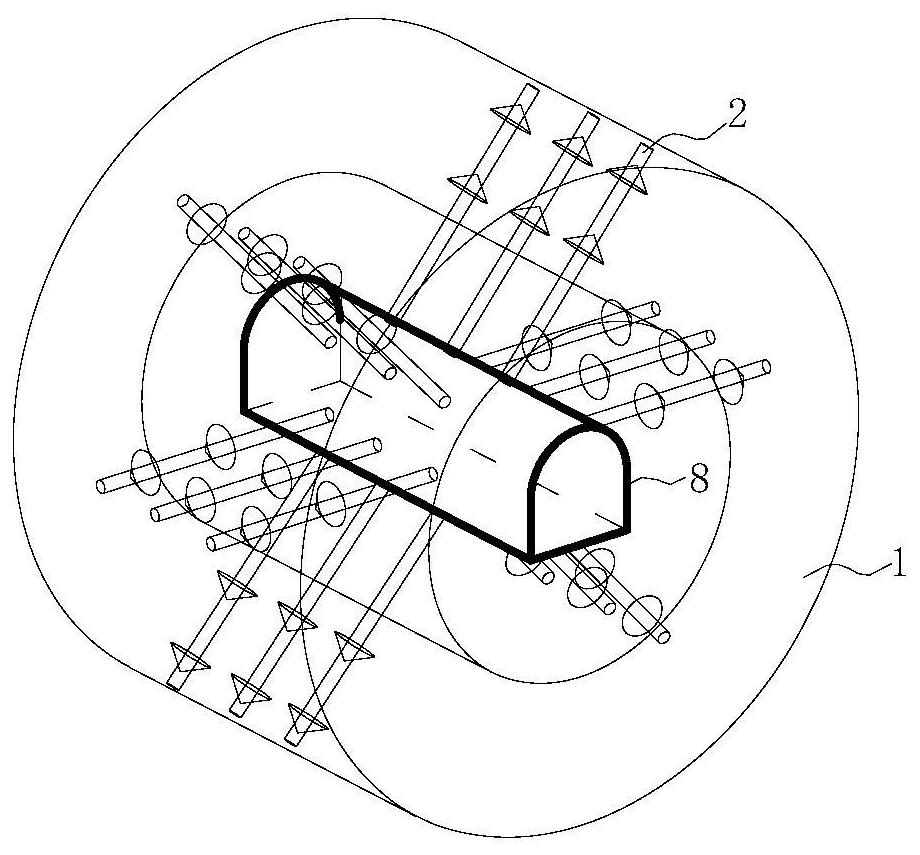

Embodiment 1

[0034] Thick coal seams are prone to plastic slip under the action of superimposed stress, leading to an increase in the stress of the surrounding rock of the roadway, especially under the action of external disturbance stress, the risk of rock burst in the coal body increases. An all-round pressure relief method for dangerous rockburst roadways in thick coal seam working faces, which is applied to mining roadways in thick coal seam working faces, and can avoid the influence of external stress disturbance on roadways. The specific steps are:

[0035] A. When the roadway is excavated to the rock burst dangerous area, the pressure relief method and pressure relief parameters shall be determined according to the mining conditions and geological conditions.

[0036] The risk area of rock burst is determined by using the comprehensive index method or the possibility index method, and according to the coal seam burst tendency, mining depth, roof and floor lithology, tectonic stress...

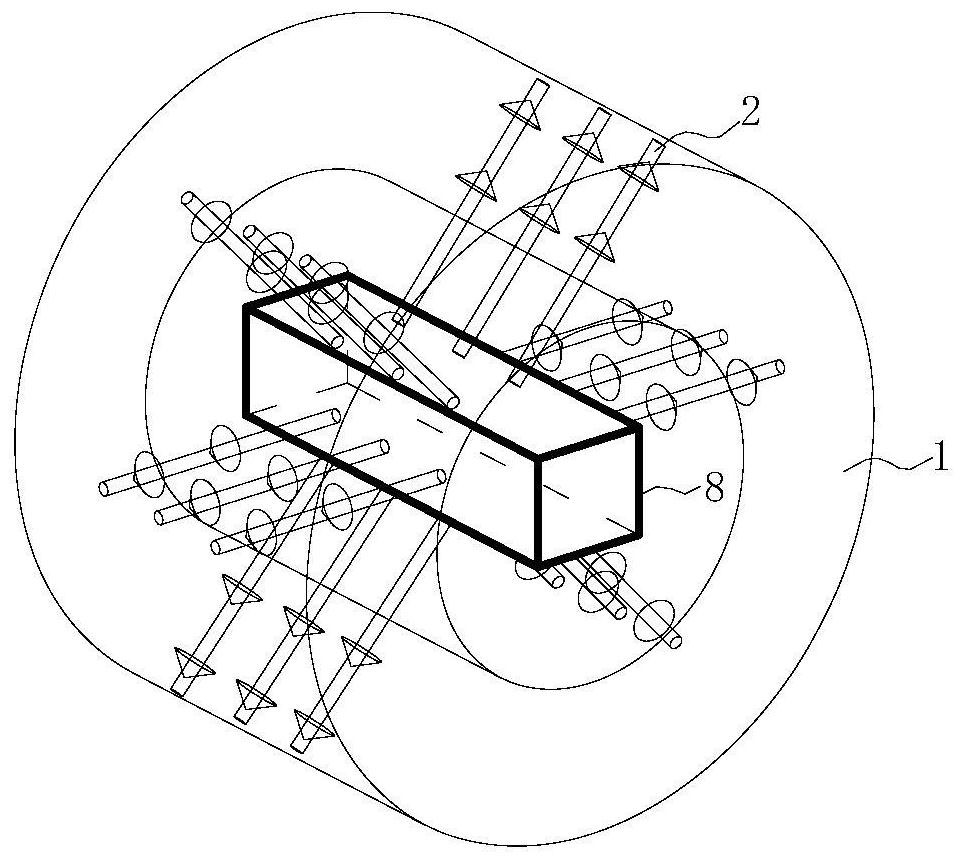

Embodiment 2

[0049]In this embodiment, taking a certain mine as an example, an all-round pressure relief method and its beneficial effects are described for a dangerous rockburst roadway in a thick coal seam working face.

[0050] A mine field is a Carboniferous and Permian coalfield of North China type, and the strata from top to bottom are Quaternary, Upper Tertiary, Upper Shihezi Formation of Upper Permian System, Lower Shihezi Formation and Shanxi Formation of Lower System, Carboniferous The Taiyuan Formation of the Upper System and the Benxi Formation of the Central System. The main coal seam of the mine is 3 coal seams with an average thickness of 3.78m. The coal seam thickness of the 3301 working face is 6.0m, and the air inlet and return roadway of the working face adopts a rectangular section with a net width of 4.4m and a net height of 3.8m, and the top coal construction is carried out. The top plate adopts Φ22×2400 (mm) left-handed threaded steel anchor rod without longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com