A high-precision drilling imaging method and device for array acoustic wave scanning

A drilling imaging, high-precision technology, used in earthwork drilling, surveying, wellbore/well components, etc., can solve problems such as low accuracy and distortion of acoustic drilling imaging results, achieve simplified structural components, rich detection data, The effect of significant scientific significance and economic practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing and implementation example the present invention is further described:

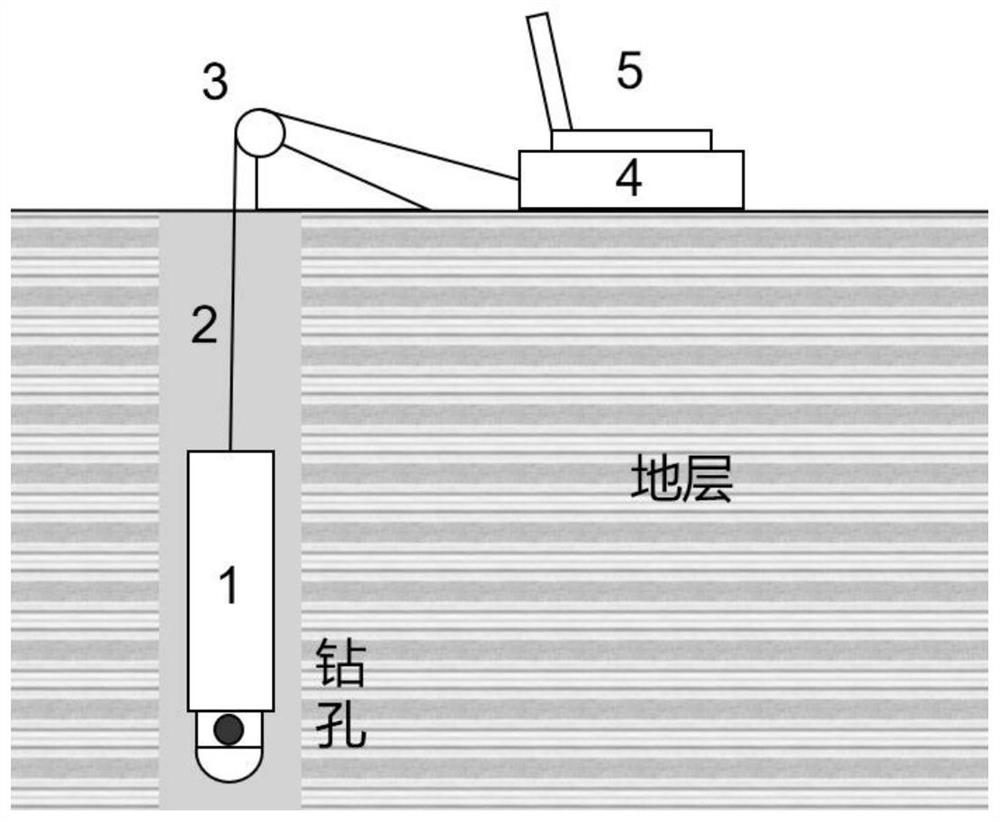

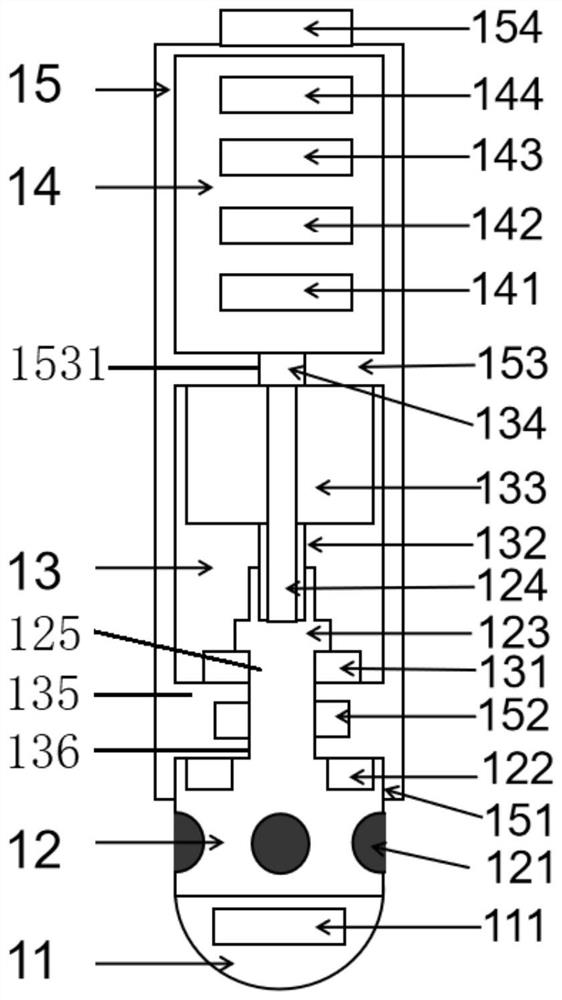

[0059] A high-precision borehole imaging device for array acoustic wave scanning, which mainly includes five parts: an in-hole probe 1, a transmission cable 2, a depth encoder 3, an integrated control box 4, and an industrial computer 5;

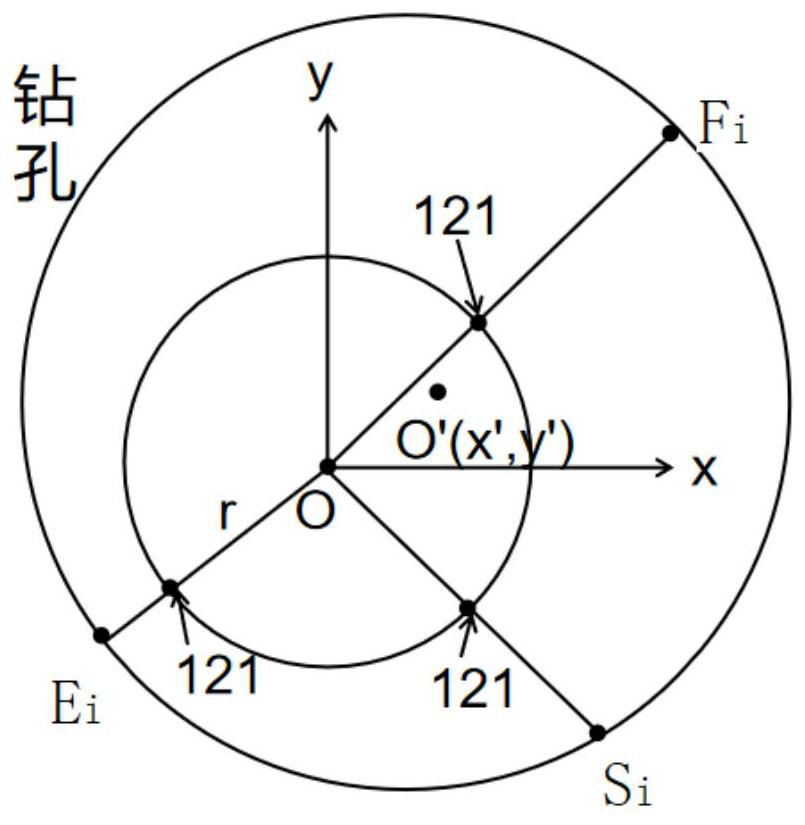

[0060] Such as figure 1 As shown, the borehole probe 1 is mainly responsible for collecting data in the borehole. The borehole probe 1 is placed inside the borehole to work. The transmission cable 2 is mainly used to upload the data of the borehole probe 1 to the ground. The depth encoder 3 is mainly used for The depth of the borehole where the probe 1 is located is collected in real time, the depth encoder 3 is usually placed in the borehole, the transmission cable 2 is connected to the integrated control box 4 on the ground, and the integrated control box 4 is used for data demodulation and power supply , the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com