Multielement material co-extrusion refrigerator door seal

A refrigerator door and multi-component technology, applied in household refrigerators, windows/doors, sealing devices, etc., can solve problems such as low fit between door seals and refrigerator cabinets, easy gaps and twisted edges, loss of refrigerator insulation performance, etc. , to achieve the effect of avoiding loss of thermal insulation performance, good stability and appropriate rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

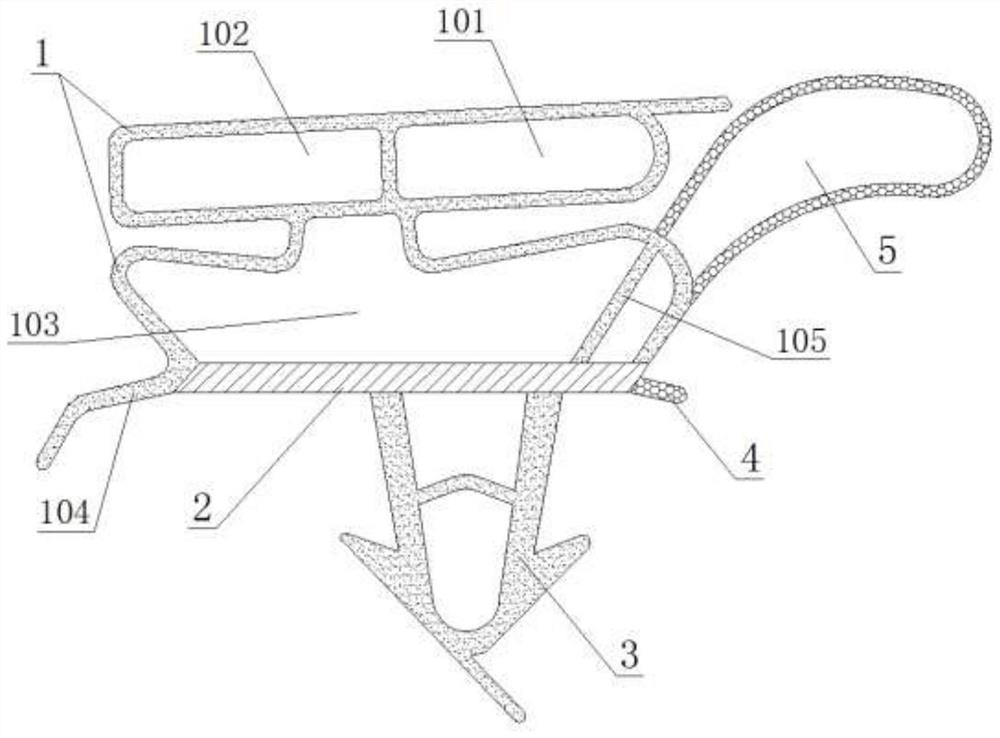

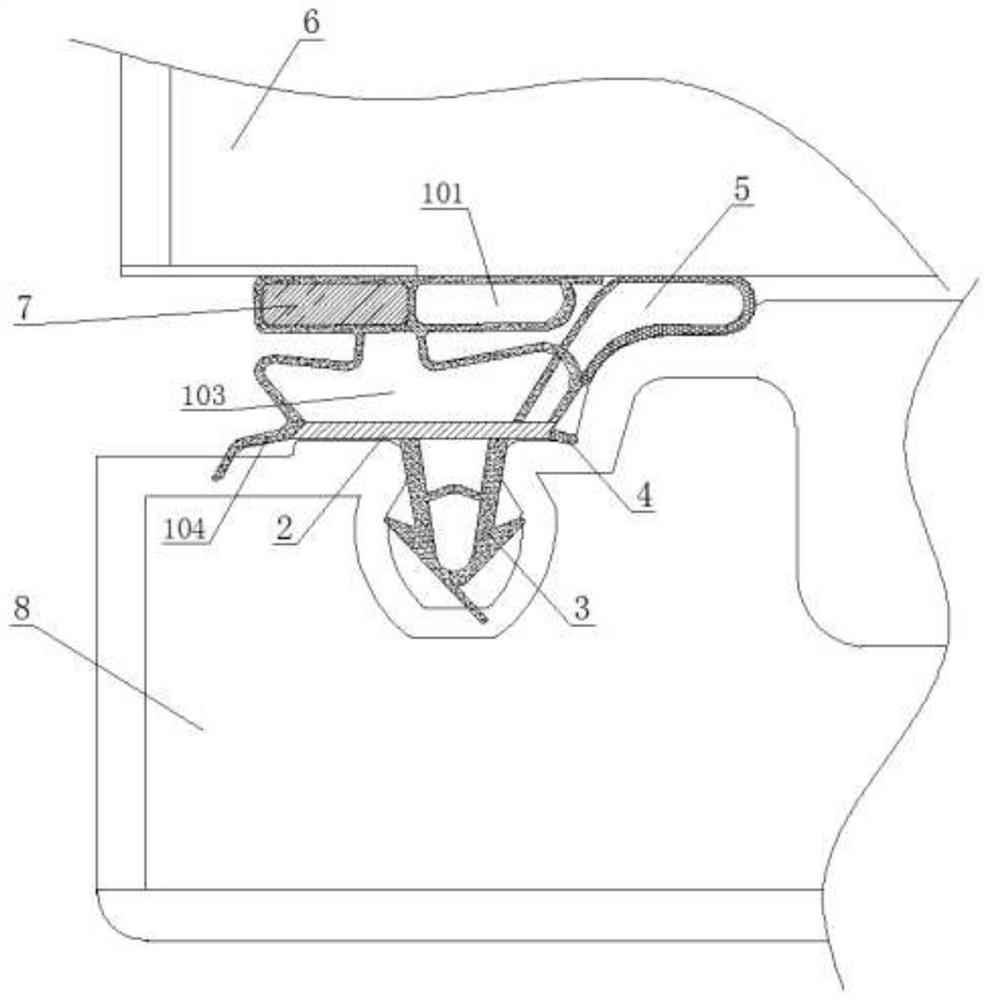

[0019] Such as figure 1 , figure 2 As shown, a multi-material co-extrusion refrigerator door seal is characterized in that it includes a main structure 1, a beam 2, a buckle 3, an inner wing edge 4 and a step airbag 5, the main structure 1 is located on the upper side of the beam 2, and the buckle 3 Located on the lower side of the crossbeam 2, the inner winglet 4 is located on the right side of the crossbeam 2, and the step airbag 5 is located on the right side of the main structure 1, and the main structure 1, the crossbeam 2, the buckle 3, the inner winglet 4 and the step airbag 5 are connected as one , the main structure 1 has a compensation airbag 103, a connecting airbag 101, a magnetic strip cavity 102, an outer small wing edge 104 and a rib surface 105, the compensation airbag 103 is located on the upper side of the beam 2, and the reinforcement surface 105 is located inside the compensation airbag 103 On the right side, the lower side of the rib surface 105 is conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com