Zero-VOC quick-drying scratch-resistant bright black finish paint and preparation method thereof

A scratch-resistant and bright technology, applied in the field of coatings and paints, can solve problems such as product shipment rate affecting production efficiency, poor scratch-resistant performance, and pollution of the atmospheric environment, achieve excellent scratch-resistant performance, improve production environment, Good construction tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

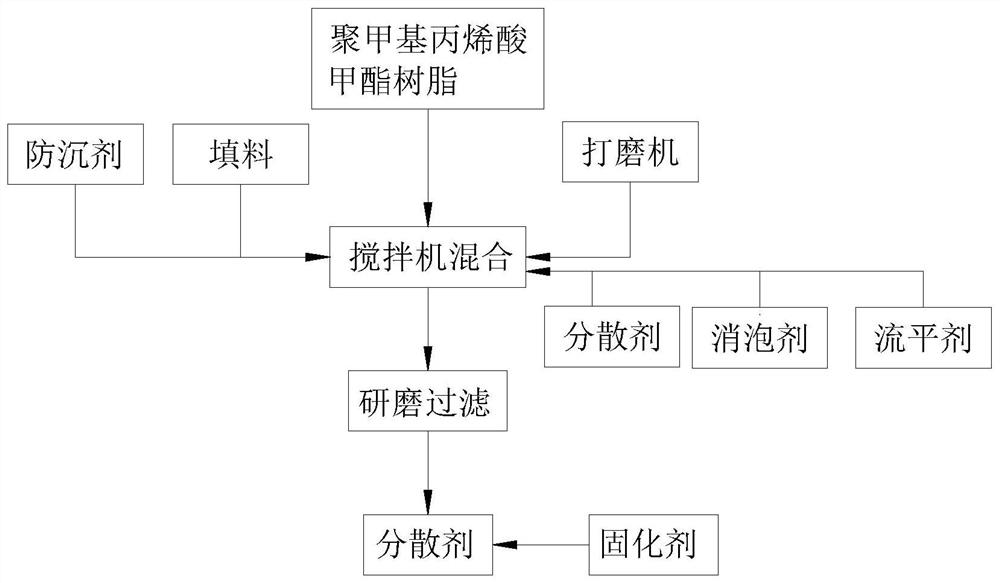

[0026] Steps for preparing the zero-VOC quick-drying and scratch-resistant glossy black topcoat of the present invention:

[0027] Step 1: Prepare the main paint:

[0028] Step 1: Weigh raw materials according to the following mass percentages: 93% polymethyl methacrylate resin, 5% carbon black, 0.3% anti-settling agent, 1% dispersant, 0.4% defoamer, and 0.3% leveling agent;

[0029] Step 2: Put 80% polymethyl methacrylate resin, anti-sedimentation agent and dispersant into the dispersion tank, disperse at 800-1000 rpm for 10 minutes, and disperse evenly;

[0030] The third step: Put the carbon black in the formula into the dispersion tank, disperse at a high speed of 1200-1500 rpm for 15 minutes, and then grind it with a sand mill until the fineness is less than 15um, and use the remaining polymethyl methacrylate Resin Clean the sand mill, add the remaining additives in the formula, disperse at 600-800 rpm for 10 minutes, and disperse evenly to obtain the main paint;

[003...

Embodiment 2

[0033] Steps for preparing the zero-VOC quick-drying and scratch-resistant glossy black topcoat of the present invention:

[0034] Step 1: Prepare the main paint:

[0035] Step 1: Weigh raw materials according to the following mass percentages: 94% polymethyl methacrylate resin, 4% carbon black, 0.3% anti-settling agent, 0.9% dispersant, 0.4% defoamer, and 0.4% leveling agent;

[0036] Step 2: Put 80% polymethyl methacrylate resin, anti-sedimentation agent and dispersant into the dispersion tank, disperse at 800-1000 rpm for 10 minutes, and disperse evenly;

[0037] The third step: Put the carbon black in the formula into the dispersion tank, disperse at a high speed of 1200-1500 rpm for 15 minutes, and then grind it with a sand mill until the fineness is less than 15um, and use the remaining polymethyl methacrylate Resin Clean the sand mill, add the remaining additives in the formula, disperse at 600-800 rpm for 10 minutes, and disperse evenly to obtain the main paint;

[0...

Embodiment 3

[0040] First prepare the steps of the zero-VOC quick-drying scratch-resistant glossy black topcoat of the present invention:

[0041] Step 1: Prepare the main paint:

[0042] Step 1: Weigh raw materials according to the following mass percentages: 96% polymethyl methacrylate resin, 2% carbon black, 0.2% anti-settling agent, 0.8% dispersant, 0.6% defoamer, and 0.4% leveling agent;

[0043] Step 2: Put 80% polymethyl methacrylate resin, anti-sedimentation agent and dispersant into the dispersion tank, disperse at 800-1000 rpm for 10 minutes, and disperse evenly;

[0044] The third step: Put the carbon black in the formula into the dispersion tank, disperse at a high speed of 1200-1500 rpm for 15 minutes, and then grind it with a sand mill until the fineness is less than 15um, and use the remaining polymethyl methacrylate Resin Clean the sand mill, add the remaining additives in the formula, disperse at 600-800 rpm for 10 minutes, and disperse evenly to obtain the main paint;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com