Asphalt filling system and control method of asphalt filling system

The technology of a filling system and control method is applied in the field of asphalt filling system and the control field of asphalt filling system, which can solve the problems of low filling efficiency of asphalt mixing station, avoid filling overflow of asphalt, improve transportation and filling The effect of improving efficiency and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

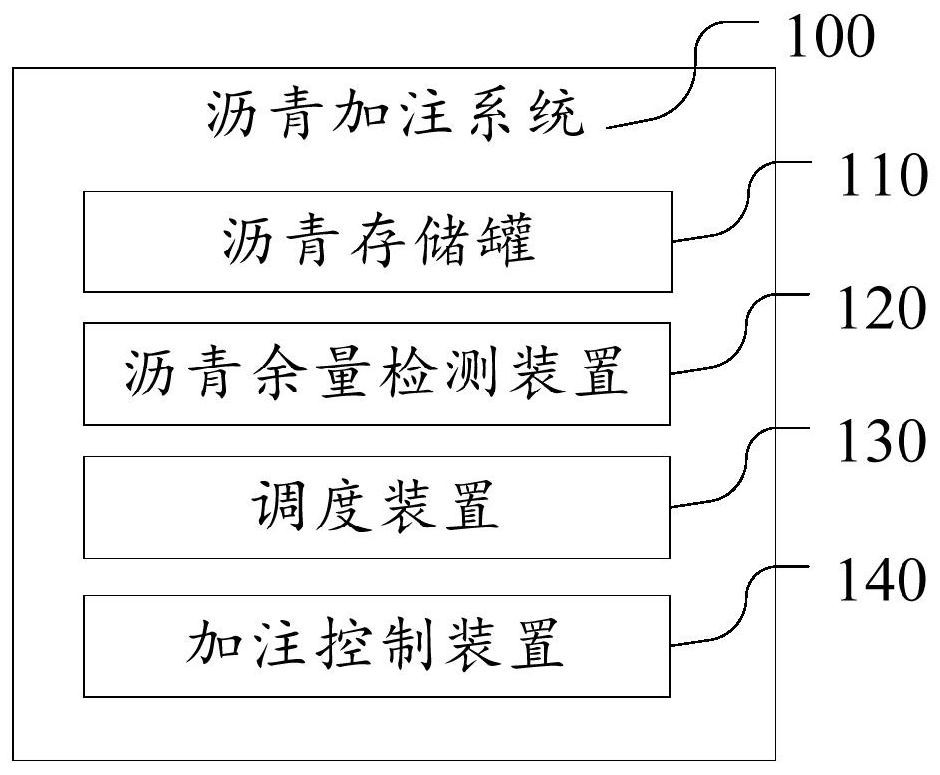

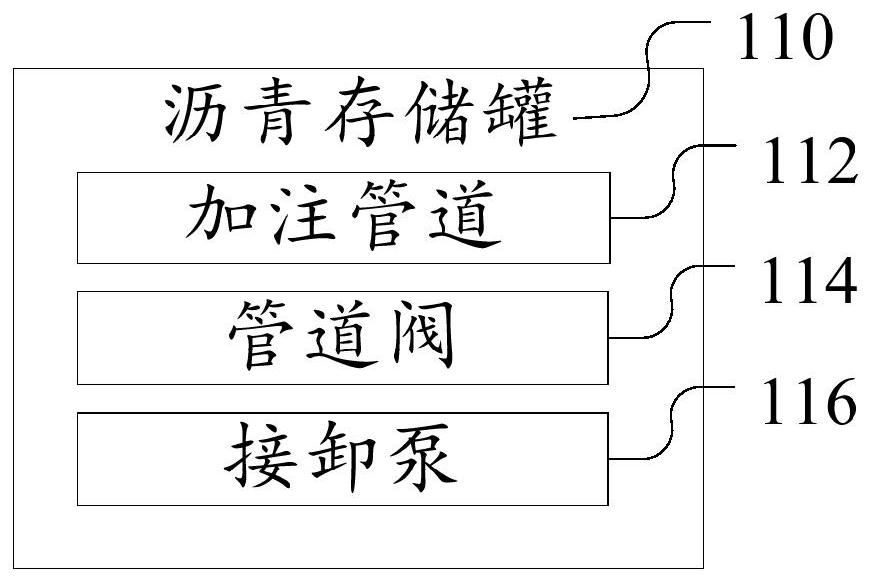

[0043] Such as figure 1 and figure 2As shown, the present embodiment provides an asphalt filling system 100, including: a plurality of asphalt storage tanks 110, suitable for storing asphalt, each asphalt storage tank 110 is provided with a filling pipeline 112, and the filling pipeline 112 is provided with Pipeline valve 114, the inlets of multiple filling pipelines 112 are connected to the same unloading pump 116; the asphalt residual detection device 120, detects the residual information of asphalt in each asphalt storage tank 110; the dispatching device 130, and the asphalt residual detection device 120 communication connection, to read the residual information of the asphalt residual detection device 120, the dispatching device 130 outputs the residual information and receives the manual order filling instruction; the filling control device 140, and the asphalt residual detection device 120, the dispatching device 130, the pipeline valve 114 and the unloading pump 116 a...

Embodiment 2

[0048] This embodiment provides an asphalt filling system 100. In addition to the technical features of the above embodiments, this embodiment further includes the following technical features.

[0049] The asphalt residual detection device 120 is connected to the dispatching device 130 via an Ethernet network.

[0050] In this embodiment, the asphalt residual detection device 120 and the dispatching device 130 are configured to perform information interaction through the Ethernet network, so as to ensure the interaction and transmission efficiency and effect of the two.

Embodiment 3

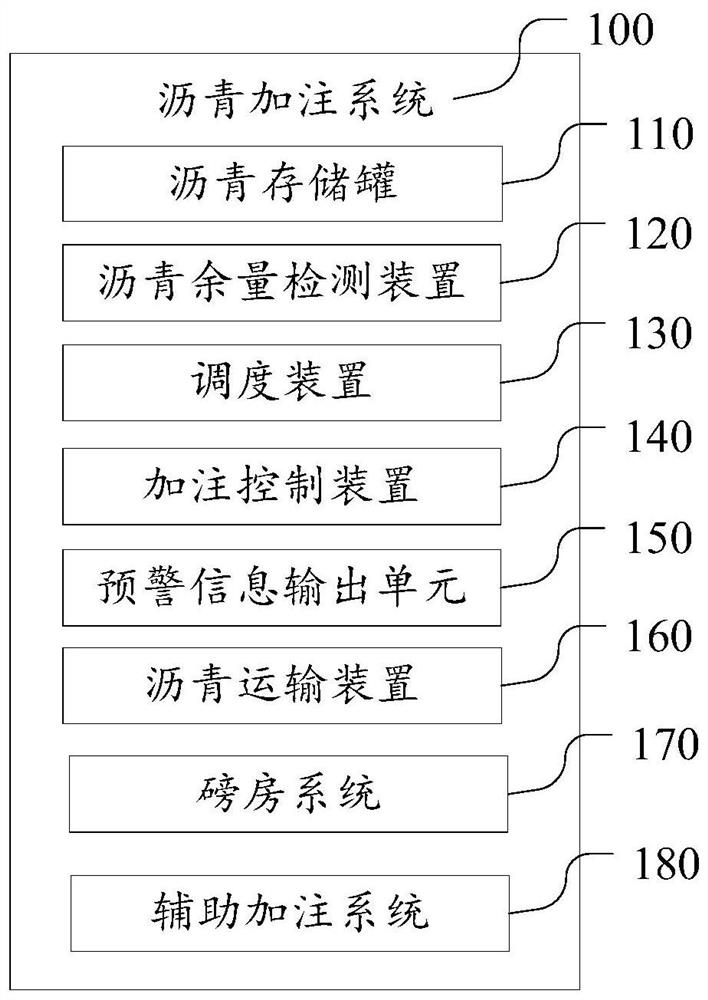

[0052] Such as image 3 As shown, this embodiment provides an asphalt filling system 100. In addition to the technical features of the above-mentioned embodiments, this embodiment further includes the following technical features.

[0053] The asphalt filling system 100 also includes: an early warning information output unit 150 connected to the filling control device 140; wherein the filling control device 140 controls the early warning information output unit 150 so that the early warning information output unit 150 outputs early warning information.

[0054] The early warning information output unit 150 in this embodiment can specifically be a display device or an acousto-optic output device, which outputs early warning information and prompts the operator when the amount of asphalt injected reaches or meets the requirements or instructions of the staff.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com