A More Stable Hoisting Equipment for Pipe Processing

A technology for hoisting equipment and pipes, which is applied in the direction of transportation, packaging, and load hanging components. It can solve the problems of cumbersome sling binding process, pipe fittings detached from the sling, troublesome use, etc., to increase friction limit, facilitate processing, and prevent detachment from the device. The effect of clip components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

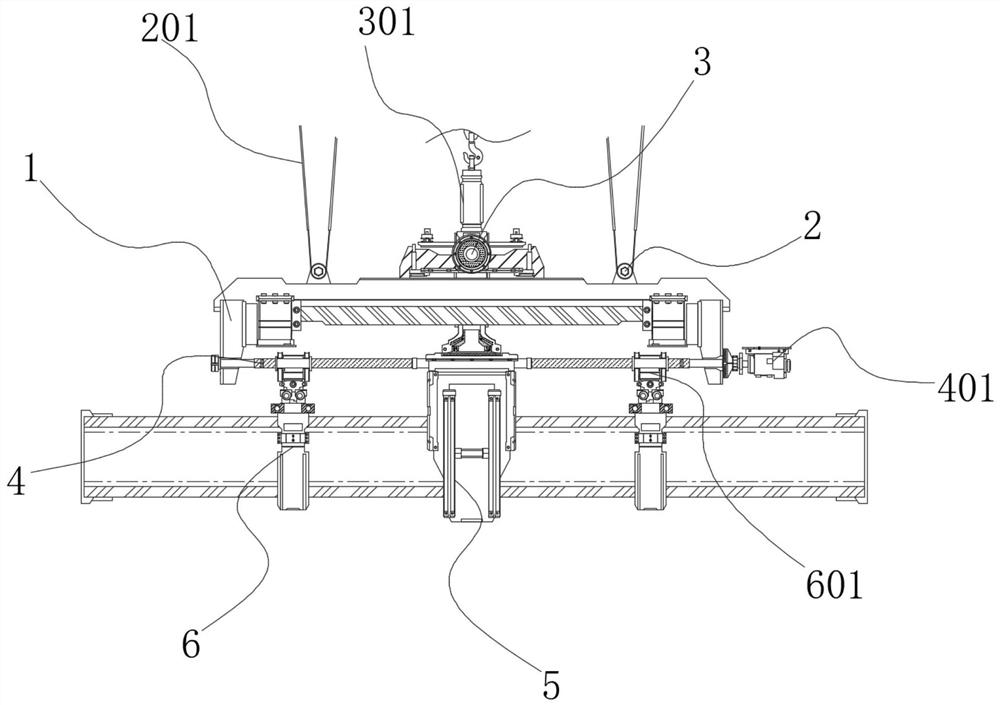

[0037] refer to figure 1 , the present invention provides a technical solution: a more stable hoisting equipment for pipe processing, which includes an outer frame 1, a central lifting assembly 5 and a side clamping assembly 6, wherein the upper end surface of the outer frame 1 A swivel base 3 is fixed in the middle position, and a main support arm 301 is rotatably connected to the swivel base 3 through a pin rod. Two pulley groups 2 are rotatably arranged on the left and right sides of the top.

[0038] At least two sections of wire ropes 201 are slidably connected to each of the pulley blocks 2, and the outer frame 1 is connected and fixed to the hoisting machine through the wire ropes 201. The outer frame is realized by adjusting the relative lengths of the wire ropes on both sides of the frame. The change of the horizontal tilt angle of the rack, the tilt angle range is set between 0° and 40°,

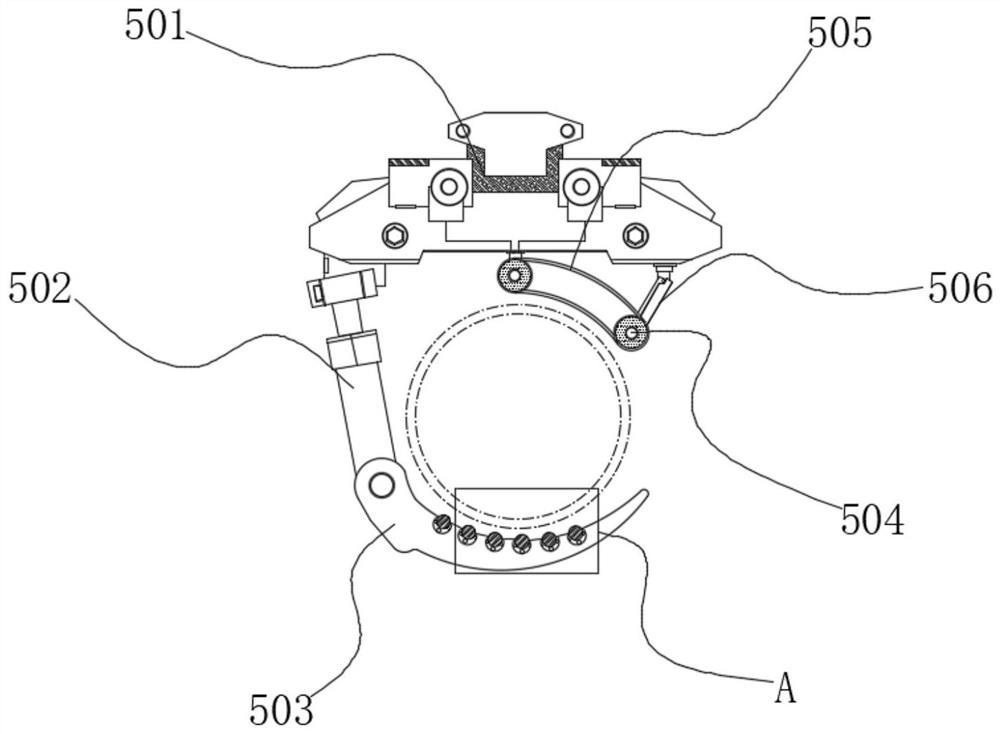

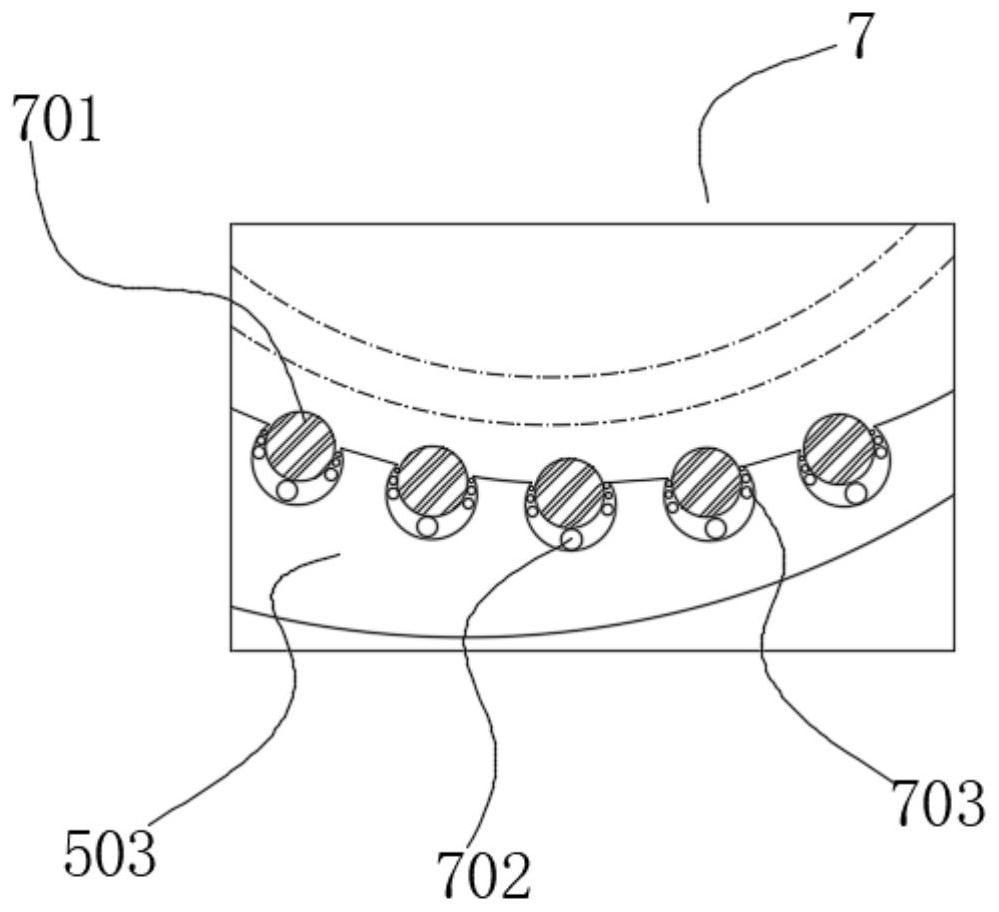

[0039] A central lifting component 5 is fixedly arranged below the outer fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com