Automatic separation and collection device for drilling three-phase mixture

An automatic separation and mixture technology, applied in filtration separation, separation methods, dispersed particle separation, etc., can solve the problems of high fluid upward return speed, low accuracy, hidden dangers of well site personnel and equipment safety, etc., to protect personnel and equipment. Safety, avoid environmental pollution, reduce the effect of export speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

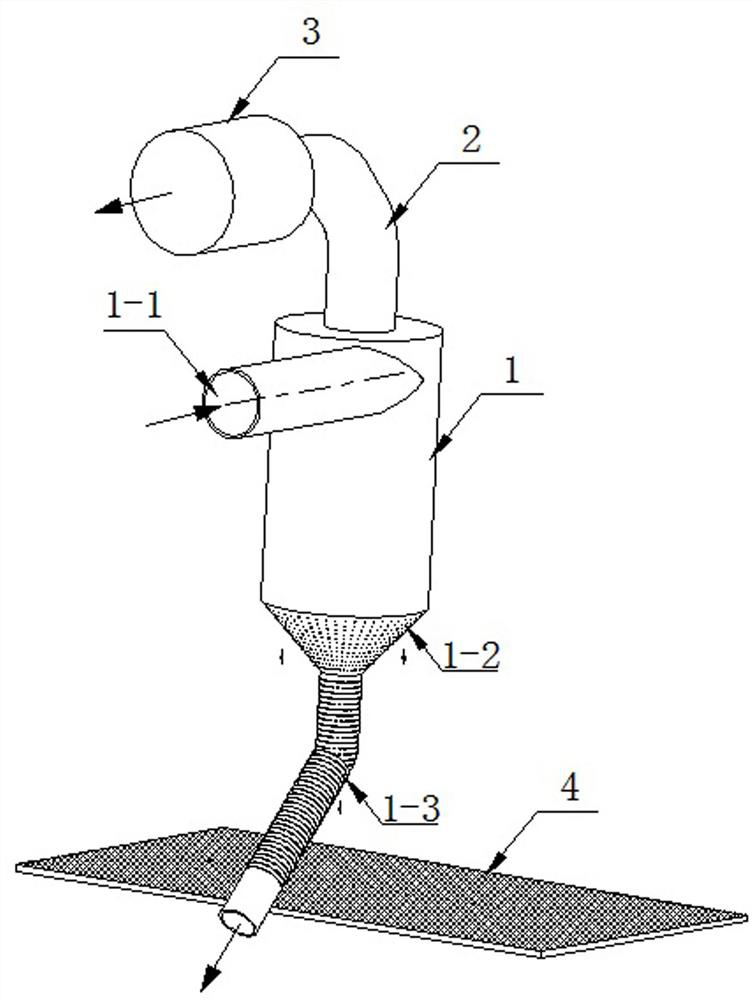

[0010] Drilling three-phase mixture automatic separation and collection device, including cyclone 1, the feed port 1-1 of cyclone 1 is arranged on the upper side wall in a tangential direction, and there is an exhaust port at the top center of cyclone 1 2. There is a filter 3 on the exhaust port 2, and a conical discharge port 1-2 with a net structure is provided at the bottom of the cyclone 1, and the end of the conical discharge port is connected to the discharge pipe 1-3. The side of the hydrocyclone 1 is provided with a vibrating screen 4, and the discharge pipe 1-3 is a bent pipe whose end stretches out from the screen of the vibrating screen 4, and the vibrating screen 4 is located on the settling tank.

[0011] The discharge pipe 1-3 is divided into two parts, the part projected on the vibrating screen 4 is a trap structure, and the part projected outside the vibrating screen 4 is an ordinary pipeline.

[0012] A fine particle solid collection box is provided at the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com