Nuclear power plant buried pipe risk monitoring system

A technology for risk monitoring and buried pipes, applied in water testing, soil material testing, measuring devices, etc., can solve the problems of lack of systematicness and pertinence, low efficiency of buried pipe management activities, etc., and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

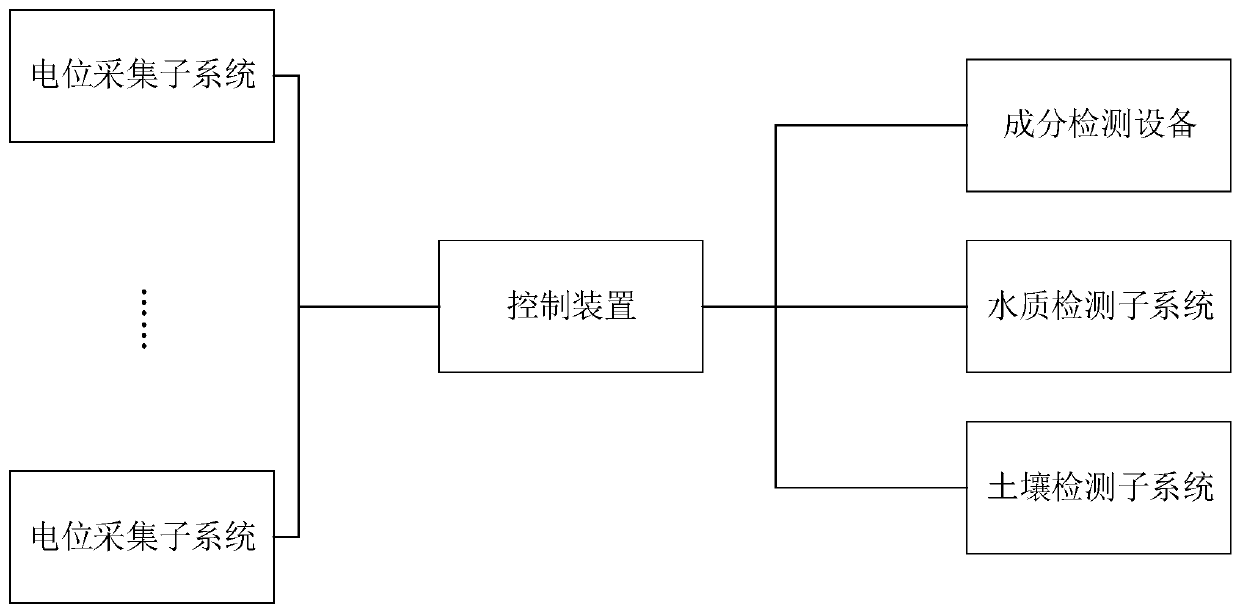

[0052] figure 1 It is a block diagram of a nuclear power plant buried pipe risk monitoring system shown according to an exemplary embodiment. Such as figure 1 As shown, the nuclear power plant buried pipe risk monitoring system includes: control device, component detection equipment, water quality detection subsystem, soil detection subsystem, multiple potential acquisition subsystems;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com