Building ground polishing device

A polishing device and floor technology, applied in grinding/polishing safety devices, surface polishing machine tools, floor leveling/polishing machines, etc., can solve problems such as low grinding efficiency, knee and waist strain, and rising dust, and achieve strength Balanced, consistent finish, and reduced spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

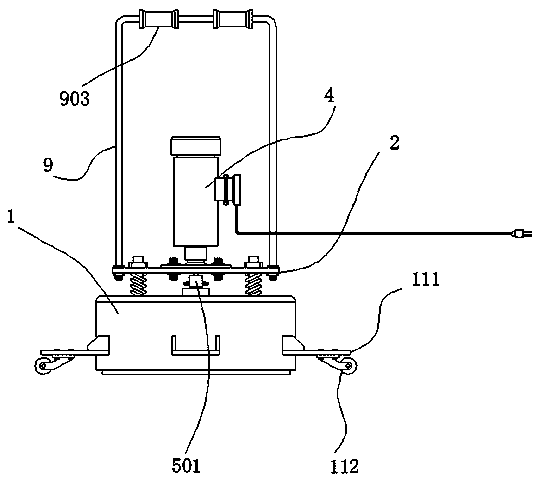

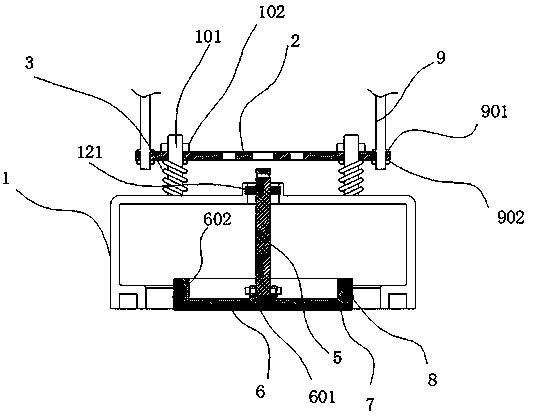

[0033] refer to figure 1 and figure 2The shown building floor polishing device includes a casing 1, and more than two guide rods 101 are annularly arranged on the upper end of the casing 1, and a movable plate 2 is assembled between the two or more guide rods 101. , the upper end of the guide rod 101 passes through the movable plate 2 and is equipped with a limit nut 102, the guide rod 101 is covered with a spring 3, and the spring 3 acts between the housing 1 and the movable plate 2 Between, a motor 4 is flange-connected at the upper end axis of the movable plate 2, and a rotating shaft 5 is interspersed at the axis of the housing 1, and a The connecting sleeve 501 is welded and fixed between the connecting sleeve 501 and the output shaft of the motor 4, and is bolted to the rotating shaft 5. The lower end of the rotating shaft 5 is equipped with a base 6, and the upper end axis of the base 6 is A connecting sleeve 601 is provided, the rotating shaft 5 is inserted into the...

Embodiment 2

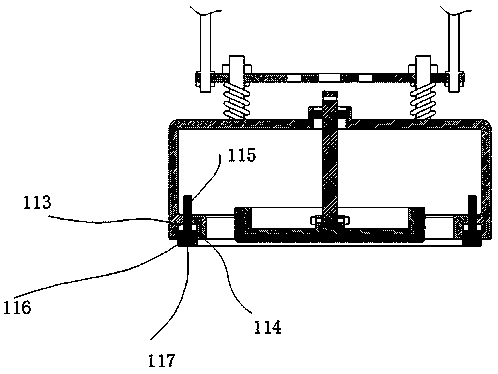

[0035] refer to image 3 As shown, an annular assembly groove 113 is provided at the bottom of the housing 1, and an annular inner ring 114 is installed in the assembly groove 113. The inner ring 114 can move up and down along the assembly groove 113. The upper end of the inner ring 114 A plurality of first guide rods 115 are welded, the first guide rods 115 pass through the assembly groove 113, a collar 116 is arranged at the bottom of the inner ring 114, and a sealing strip 117 is fitted through the collar 116 ; The sealing strip 117 contacts the ground under the action of gravity; when grinding, due to the high-speed rotation of the rotating shaft 5, the particles that are polished will be thrown out, which is dangerous, and the bottom of the shell 1 can not be effective against the ground. There may be gaps for dust leakage. For this reason, we designed the above structure. The inner ring 114 can move up and down. No matter how the shell moves on the ground, the sealing s...

Embodiment 3

[0037] refer to Figure 4 As shown, a vertical rod 991 is welded at the center of the top of the handle rod 9, a lead weight 992 for counterweight is assembled on the vertical rod 991, and a second nut is screwed on the upper end of the vertical rod 991. 993, after the lead block 992 is assembled, the movable plate 2 is pressed down. At this time, the lower end of the polishing cotton 7 touches the ground, and as the number of lead blocks 992 increases, the pressure between the polishing cotton 7 and the ground increases; The function is to increase the self-weight, and use the counterweight of the lead weight to automatically press down the spring without manual depressing. At this time, for each surface of the grinding, the applied downward force is consistent, the overall polishing is better, and no manual depressing is required. The labor force is reduced, and the staff only need to change the grinding position regularly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com