Method for deriving proper cutting condition of polarization plate

A technology for polarizers and conditions, applied in the directions of polarizers, optical elements, optical elements, etc., can solve the problems of reduced durability, inability to set the correct position of the polarizer 100, deterioration of bulk modulus adhesion, etc., to minimize leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

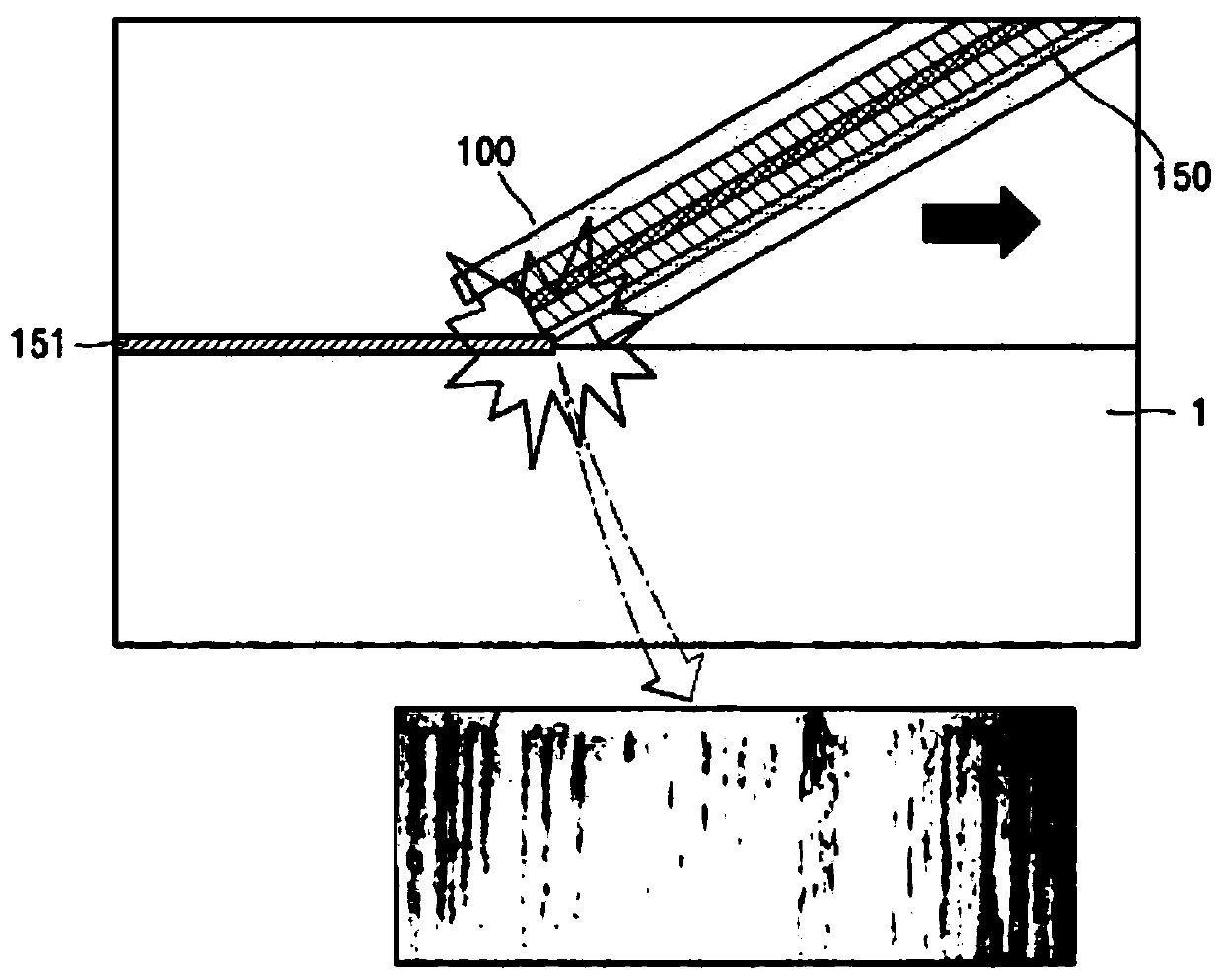

[0031] image 3 is a flowchart illustrating a method of obtaining conditions for properly cutting a polarizing plate according to the present invention, Figure 4 is a diagram showing an experimental device according to the present invention, which was made by simulating the movement of a polarizing plate to obtain conditions for properly cutting the polarizing plate.

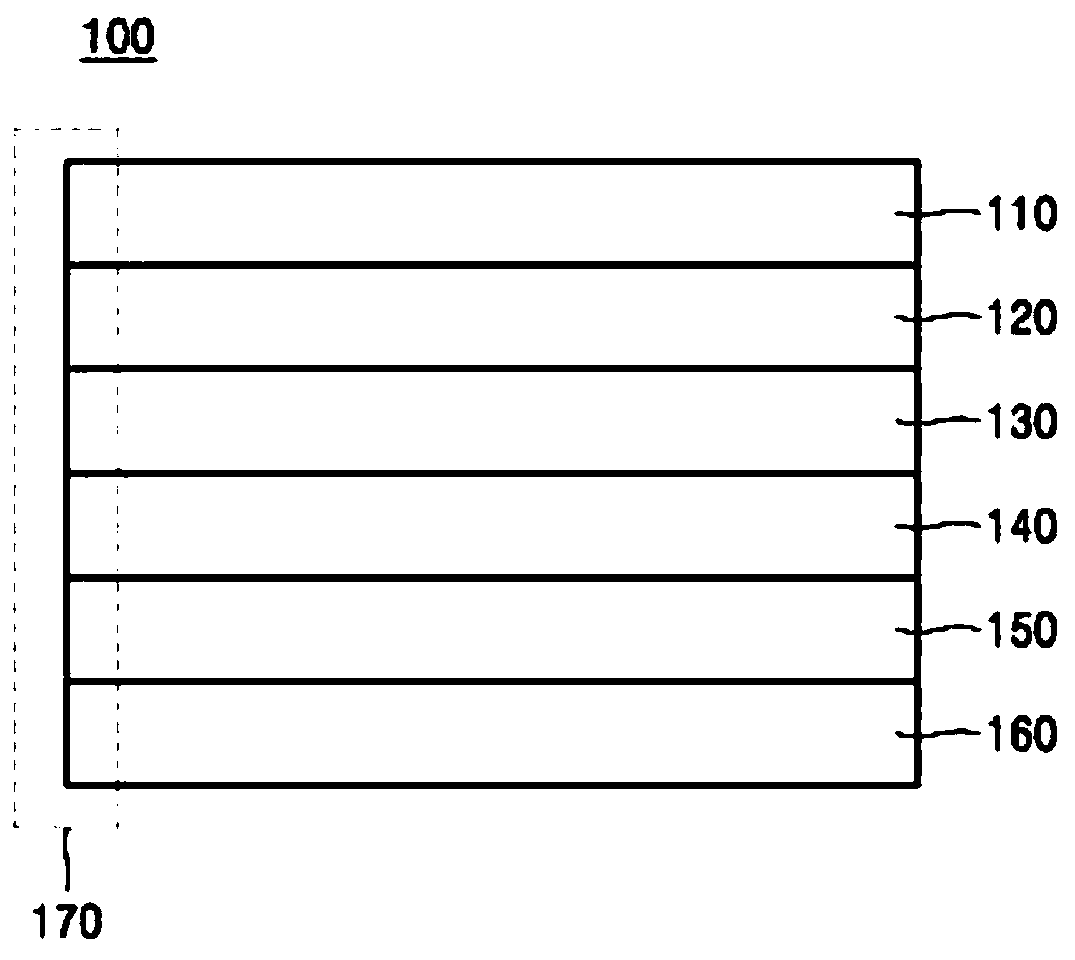

[0032] The present invention relates to a method of obtaining conditions for properly cutting a polarizing plate based on a measurement standard regarding leakage of an adhesive 151 which is previously set with respect to a frictional force applied between a polarizing plate 100 and a guide unit 200 information about the data. refer to image 3 , the method may include (a) preparing the polarizing plate 100 including the adhesive layer 150 and having the cut surface 170 formed by cutting based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com