Color-adjustable thin-film solar cell for BIPV

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of loss of photoelectric conversion efficiency of cells, increase production steps, increase costs, etc., to ensure overall structure and performance, increase utilization rate, color easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

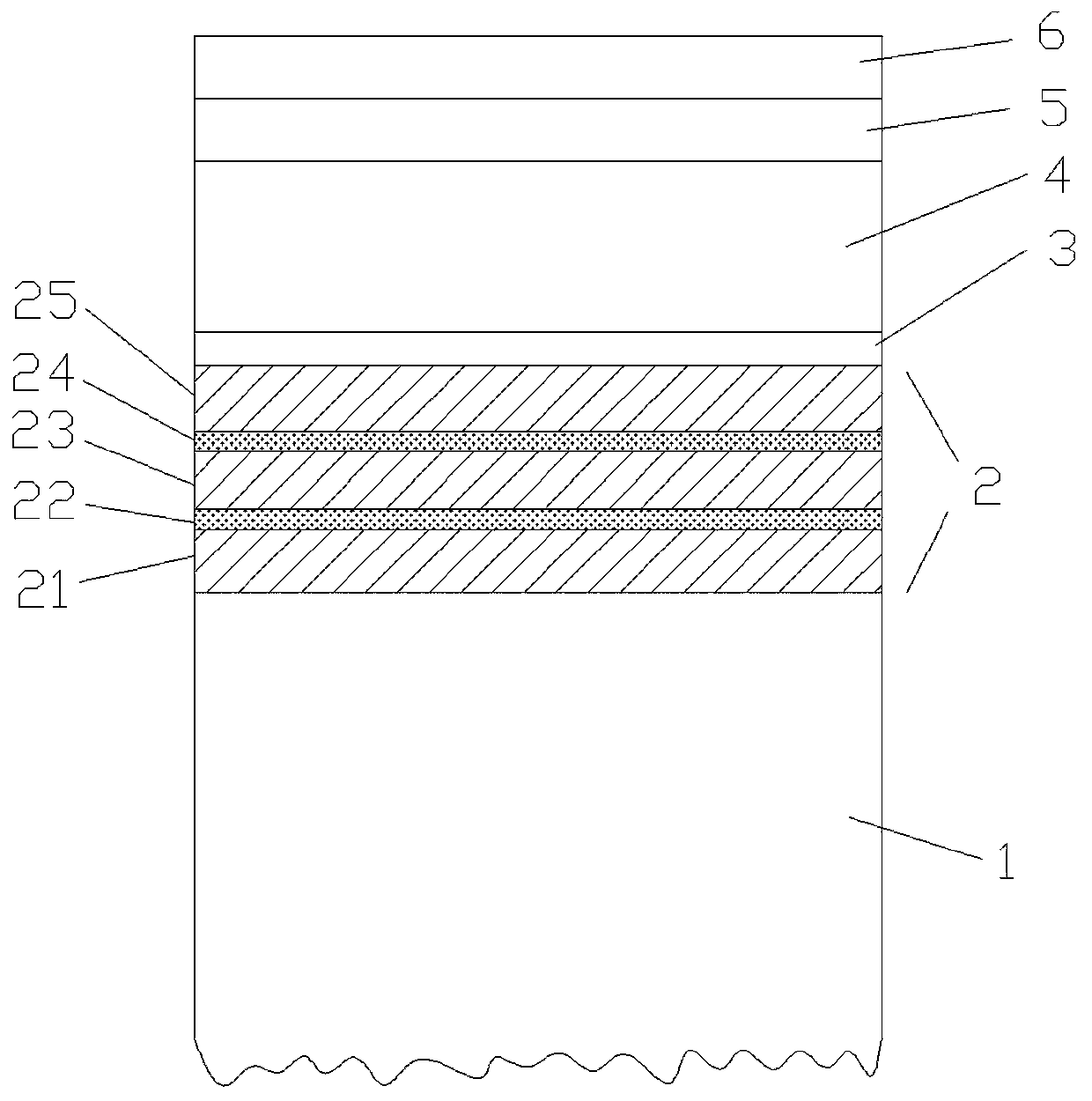

[0028] like figure 1 As shown, the present invention provides a color-tunable thin-film solar cell for BIPV,

[0029] Including a glass substrate 1, the top surface of the glass substrate 1 is sequentially laminated with a color functional layer 2, a buffer layer 3, an absorption layer 4, a back contact layer 5 and a protective layer 6; the absorption layer 4 is a CdTe film; the absorption layer 4 The thickness is 1300-2800nm.

[0030] The color functional layer 2 is composed of more than three layers of films to form a composite film layer, and the color functional layer 2 includes one or more of BZO film, AZO film, GZO film, IGZO film, and IZO film; the color function layer of this embodiment The functional layer 2 includes five layers of films, which are the first functional layer 21 , the second functional layer 22 , the third functional layer 23 , the fourth functional layer 24 and the fifth functional layer 25 from bottom to top. The refractive index of the odd-numbere...

Embodiment 2

[0040] The present invention also can have another kind of scheme:

[0041] A color-adjustable thin-film solar cell for BIPV, comprising a glass substrate 1, a color functional layer 2, a buffer layer 3, an absorbing layer 4, a back contact layer 5 and a protective layer 6 are stacked on the top surface of the glass substrate 1 sequentially from bottom to top; The absorption layer 4 is a CdTe thin film; the thickness of the absorption layer 4 is 1300-2800nm.

[0042] The color functional layer 2 is composed of more than three layers of thin films to form a composite film layer, and the color functional layer 2 includes one or more of CTO, ZTO, and ITO thin films;

[0043] The colored functional layer 2 of this embodiment includes five layers of films, which are the first functional layer 21 , the second functional layer 22 , the third functional layer 23 , the fourth functional layer 24 and the fifth functional layer 25 from bottom to top. The refractive index of the odd-numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com