Modular air supply components

A technology of assembly and assembly, which is applied in the directions of engine components, valve details, valve devices, etc., can solve problems such as application limitations, and achieve the effect of eliminating the need for redesign.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

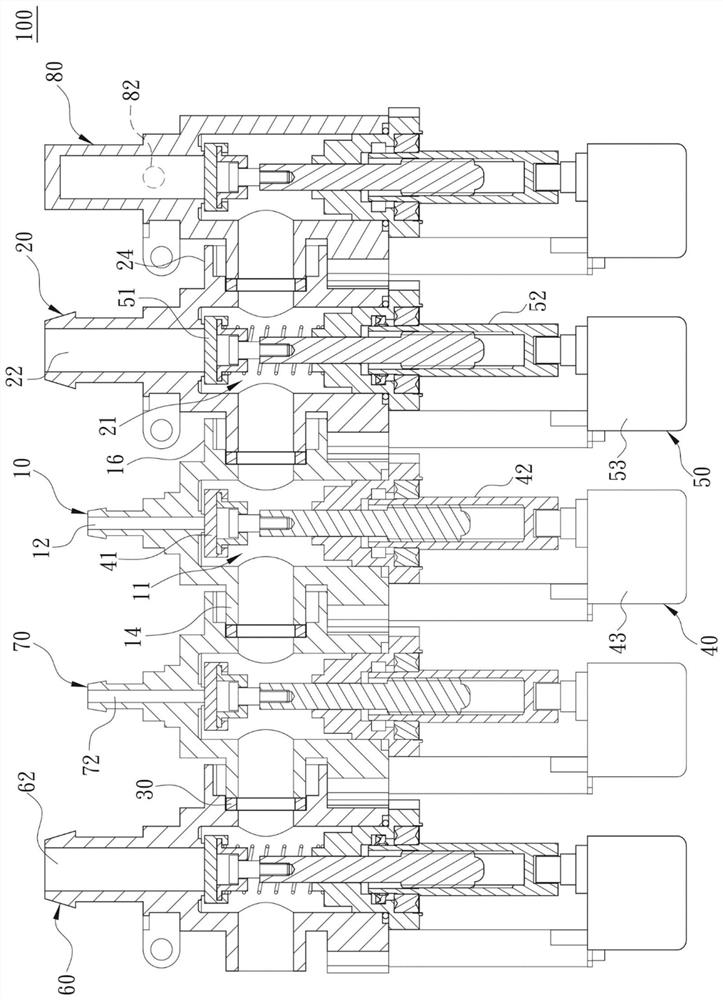

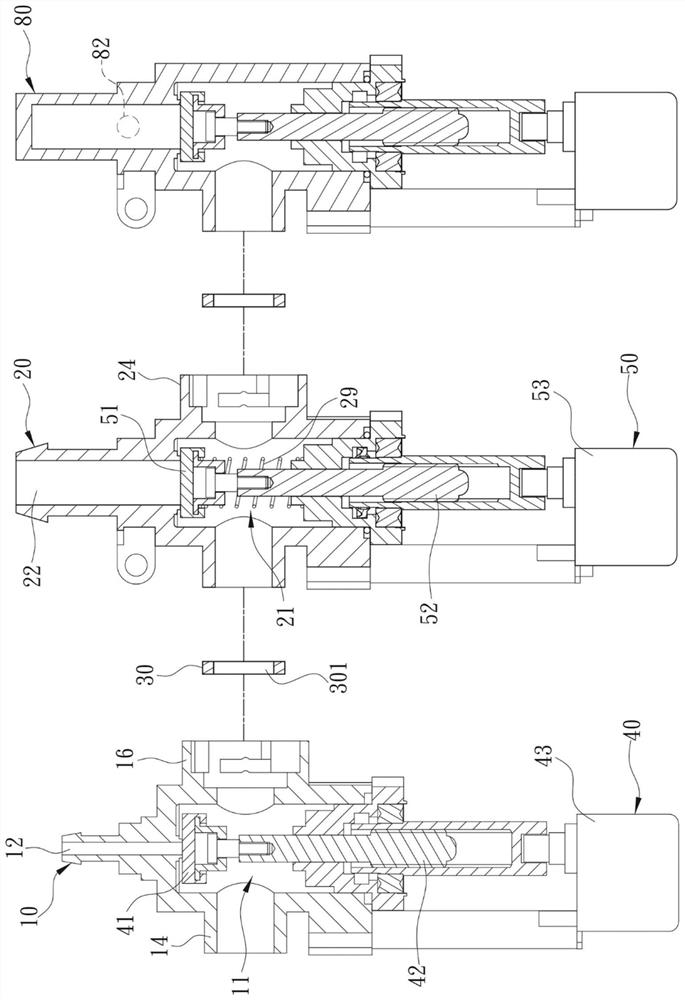

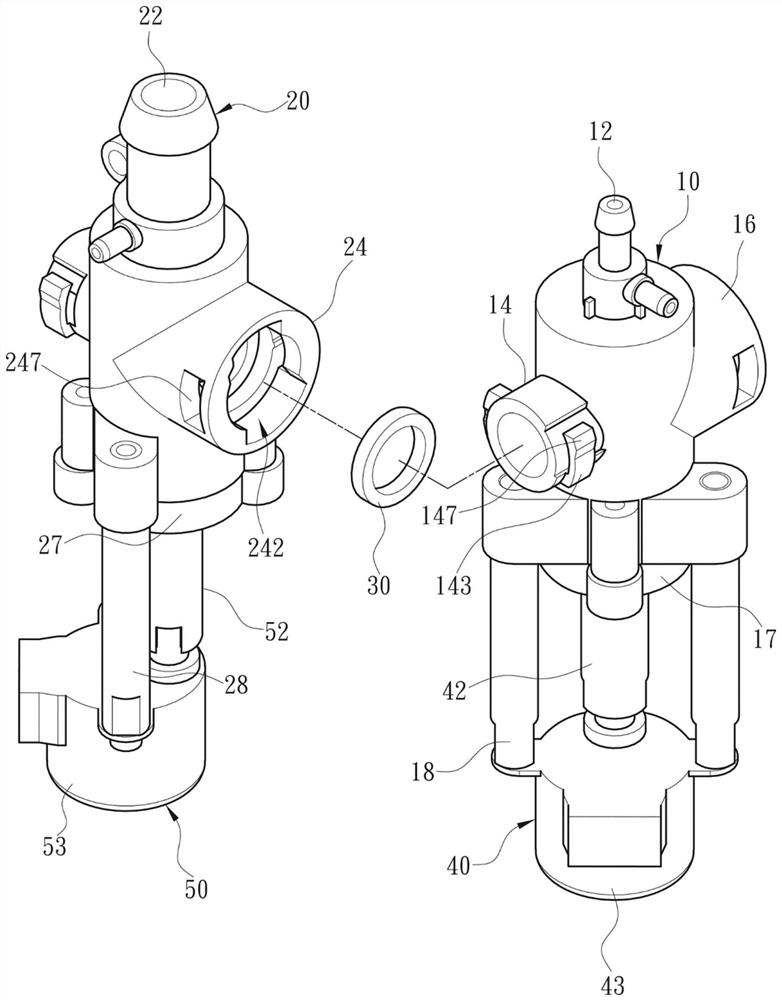

[0068] The present invention will be described in detail and technical content, and the drawing of the pattern is described below:

[0069] See Figure 1 to 4The present invention provides a dispensing air assembly 100, which includes at least one first valve seat 10 and at least one second valve seat 20, wherein the first valve seat 10 is The second valve holder 20 is independently in an independent structure, the first valve seat 10 and the second valve seat 20 can be designed according to the needs. Specifically, the first valve seat 10 forms a first ventilation space 11, a first vent 12 of the first ventilation space 11, a first valve mounting end 13 of the first ventilation space 11, and one The first assembly terminal 14 of the first ventilation space 11 is connected. Further, the second valve seat 20 forms a second ventilation space 21, a second exhaust port 22 of the second ventilation space 21, and a second valve mounting end 23 and a connection between the second ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com