Device for baking high-activity magnesium oxide

A magnesia device and high-activity technology, applied in the field of magnesia production equipment, can solve problems such as waste of resources, dust leakage, pollution of the environment, secondary pollution, etc., to improve heat exchange efficiency, ensure separation efficiency, and prevent material collapse and short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

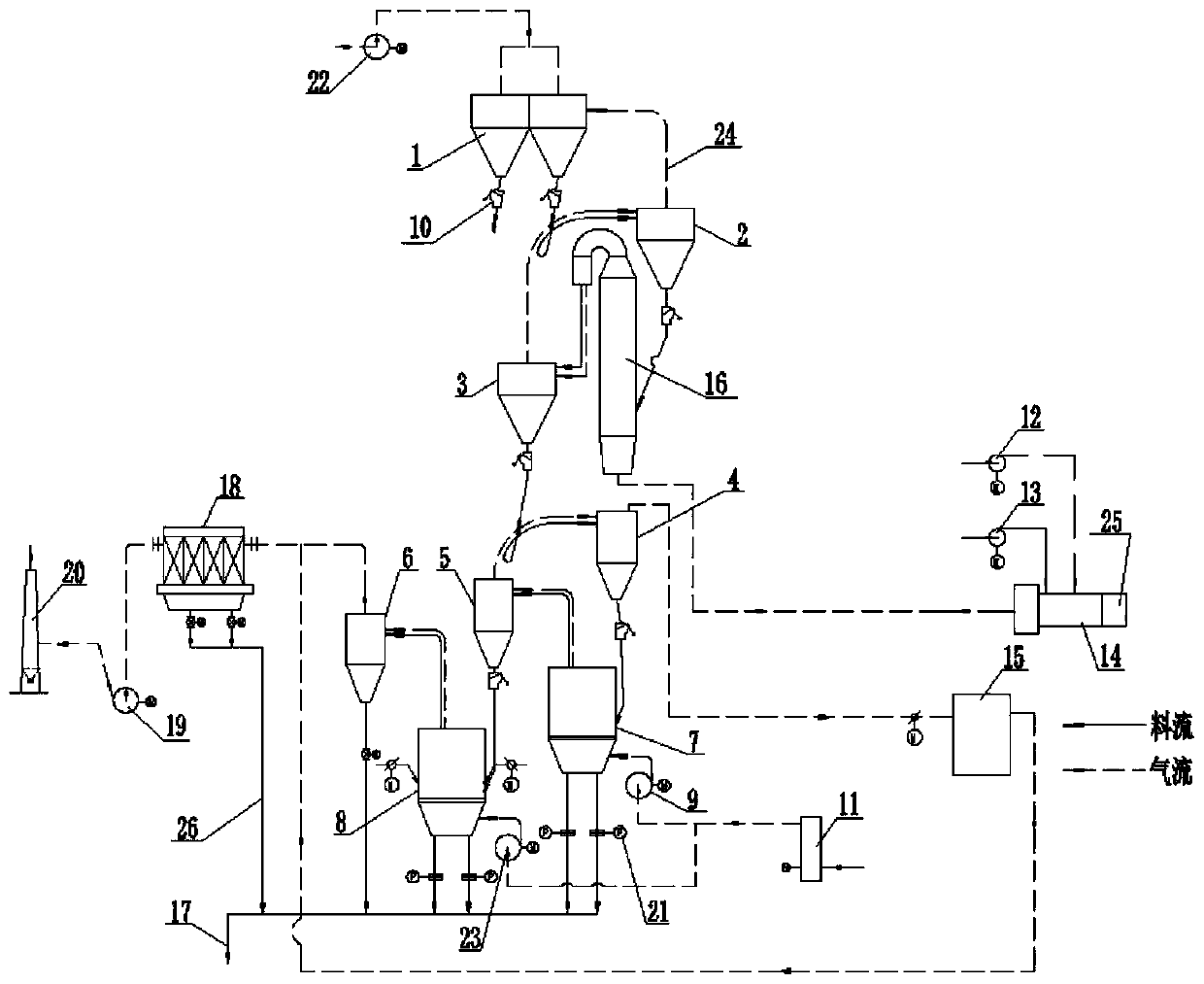

[0030] refer to figure 1 , the present invention proposes a device for burning high-activity magnesia, comprising a waste heat boiler 15, a calciner 16 and a dust collector 18, the feed port of the calciner 16 passes through the feed pipe 26 and the discharge port of the second cyclone separator 2 Connect, the discharge port of calciner 16 is connected with the feed inlet of the third cyclone separator 3 by discharge pipe, the air inlet of calciner 16 is connected with hot blast stove 14 by ventilation pipe 24, and the air inlet of hot blast stove 14 is through ventilating Pipe 24 is connected with primary fan 12 and mixed air blower 13, and hot blast stove 14 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com