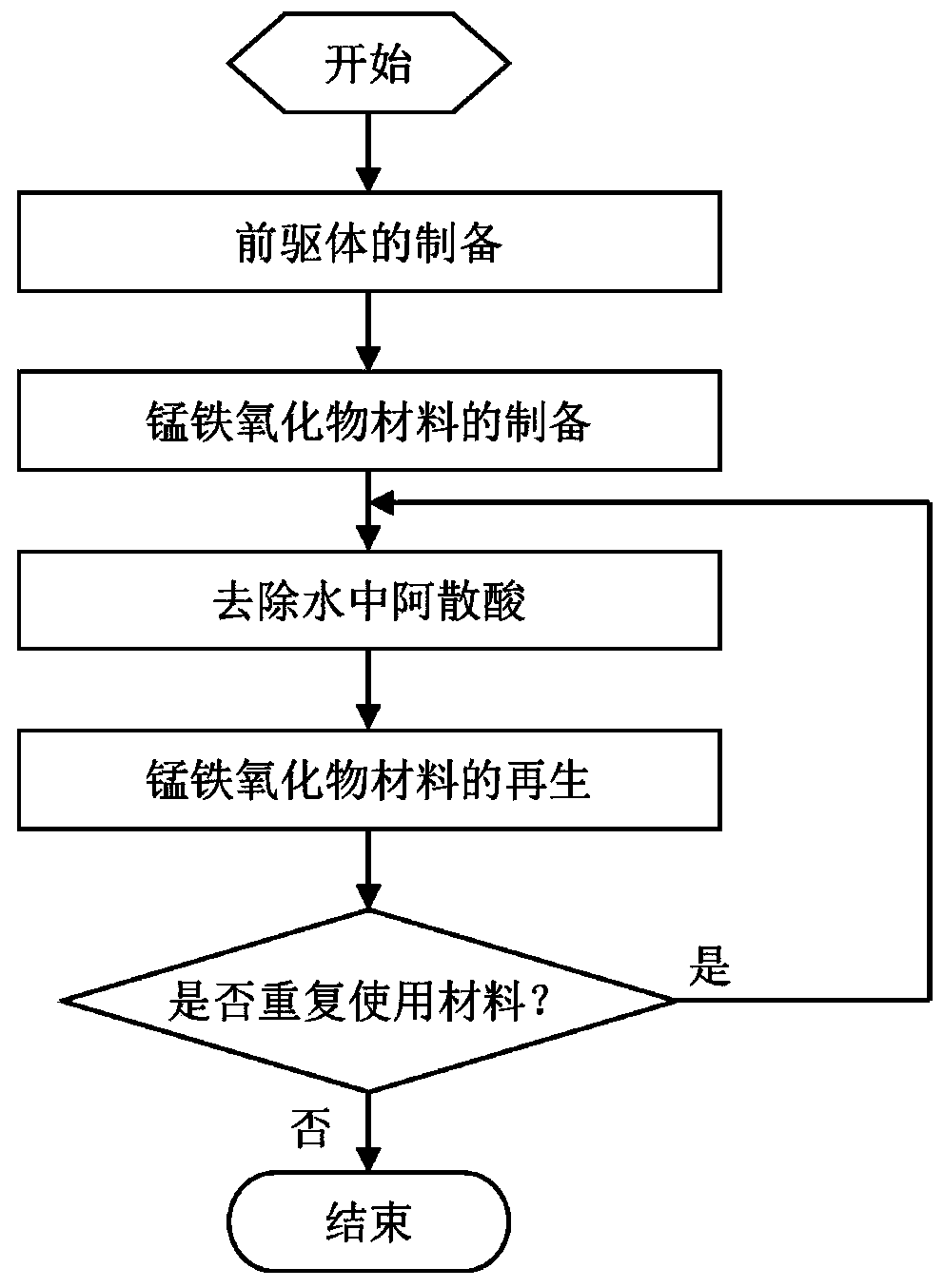

Method for removing arsanilic acid in water by adopting ferromanganese oxide material

A technology of ferromanganese oxide and assulfuric acid, which is applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of lack of assulfuric acid treatment technology, reduce the total arsenic concentration, and achieve high removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

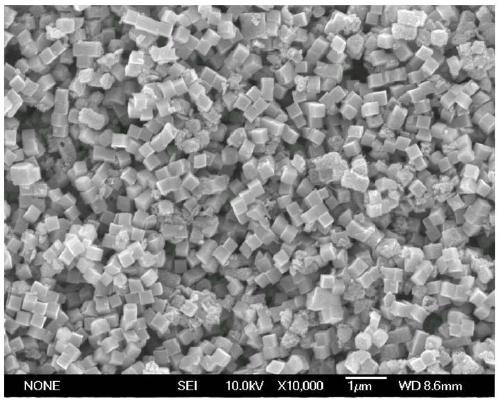

[0056] The preparation of embodiment 1 ferromanganese oxide material

[0057] In a clean 100mL beaker, add 59.4mg of manganous chloride tetrahydrate and 1.2g of polyvinylpyrrolidone K30, add 40mL of deionized water, and stir to dissolve. Take another clean 2mL centrifuge tube, add 64.2mg of potassium ferricyanide, add 150μL of deionized water, and ultrasonically dissolve. The entire solution in the 2mL centrifuge tube was quickly injected into the aforementioned 100mL beaker with a pipette gun, stirred rapidly at 700rpm for 30min, and left to age for 24h after the stirring was stopped. Centrifuge at 7000rpm for 3min, and discard the supernatant. Wash twice with 30mL of deionized water and twice with 30mL of 1:1 ethanol / water mixed solution, ultrasonically disperse the solid during each wash, then centrifuge at 7000rpm for 3min, and pour off the supernatant. Finally, the centrifuged product was dried in a vacuum oven at 60° C. for 24 hours to obtain the Prussian blue analogue...

Embodiment 2

[0059] The application of embodiment 2 ferromanganese oxide material to remove arsanic acid in water

[0060] Add the ferromanganese oxide material obtained in Example 1 into the solution with 10 mg / L arkanic acid as the treatment object, and the dosage is 0.4 g / L, and ultrasonically disperse. Add acetic acid / sodium acetate buffer solution to make the pH value of the solution about 4, and the dosage is 20mmol / L (calculated by acetate ion). Stir at 700 rpm. The removal rate of arsanic acid can reach 75.4% within 30 minutes; the removal rate of As element in the solution can reach 74.8% within 30 minutes.

Embodiment 3

[0061] Example 3 Application of persulfate-enhanced ferromanganese oxide material to remove arsanic acid in water

[0062] In order to obtain a better removal effect of arkanic acid and As elements in the solution, peroxymonosulfate was added to the solution after stirring for 30 minutes in Example 2, and the dosage was 0.2 g / L. The stirring speed was maintained at 700 rpm. The removal rate of arsanic acid can reach 99.0% within 1 hour; the removal rate of As in the solution can reach 95.2% within 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com