Elevator shaft construction device and construction method

A technology of construction device and elevator shaft, which is applied to hoisting devices, elevators in buildings, safety devices of hoisting equipment, etc., can solve the problems of slow elevator shaft construction, high risk, elevator car running jam or accident, etc. To achieve the effect of improving construction speed and construction quality, ensuring construction quality and reasonable construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

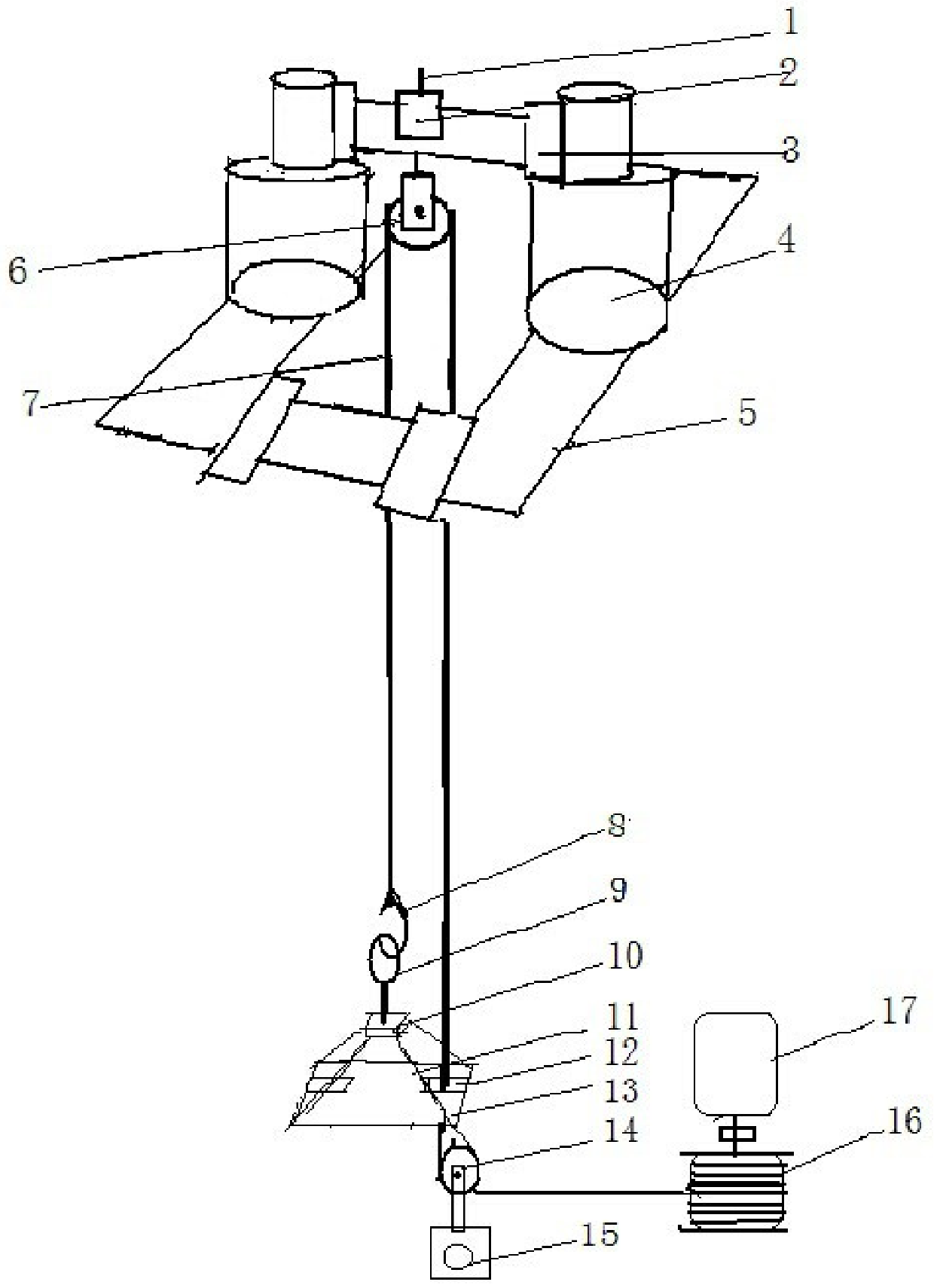

[0027] In order to further clarify the technical solution of the present invention, the following will be clearly and completely described through embodiments in conjunction with the accompanying drawings of the title book of the present invention. An elevator shaft construction device includes a driving mechanism, a suspension mechanism and a working platform, and the driving Mechanism includes self-control type speed-regulating motor 17, drum 16, wire rope 7, remote controller, and suspension mechanism includes piston type suspension frame 3, hydraulic cylinder 4, plug-in type hydraulic cylinder rectangular base 5 and suspension pulley 6. The end of the longitudinal side of the rectangular base of the hydraulic cylinder is provided with a sleeve inward and horizontally. The horizontal side is inserted into the sleeve and fixed by a pin. The hydraulic cylinder is symmetrically welded or fixed in the middle of the horizontal side. 1. The horizontal connecting sleeve welded on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com