a correction tape

A technology of correcting tape and tape feeding, which is applied in the field of stationery, can solve problems such as the degree of collision between ratchet and pawl, and the influence of others, so as to reduce noise, ensure normal use, and reduce the frequency of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

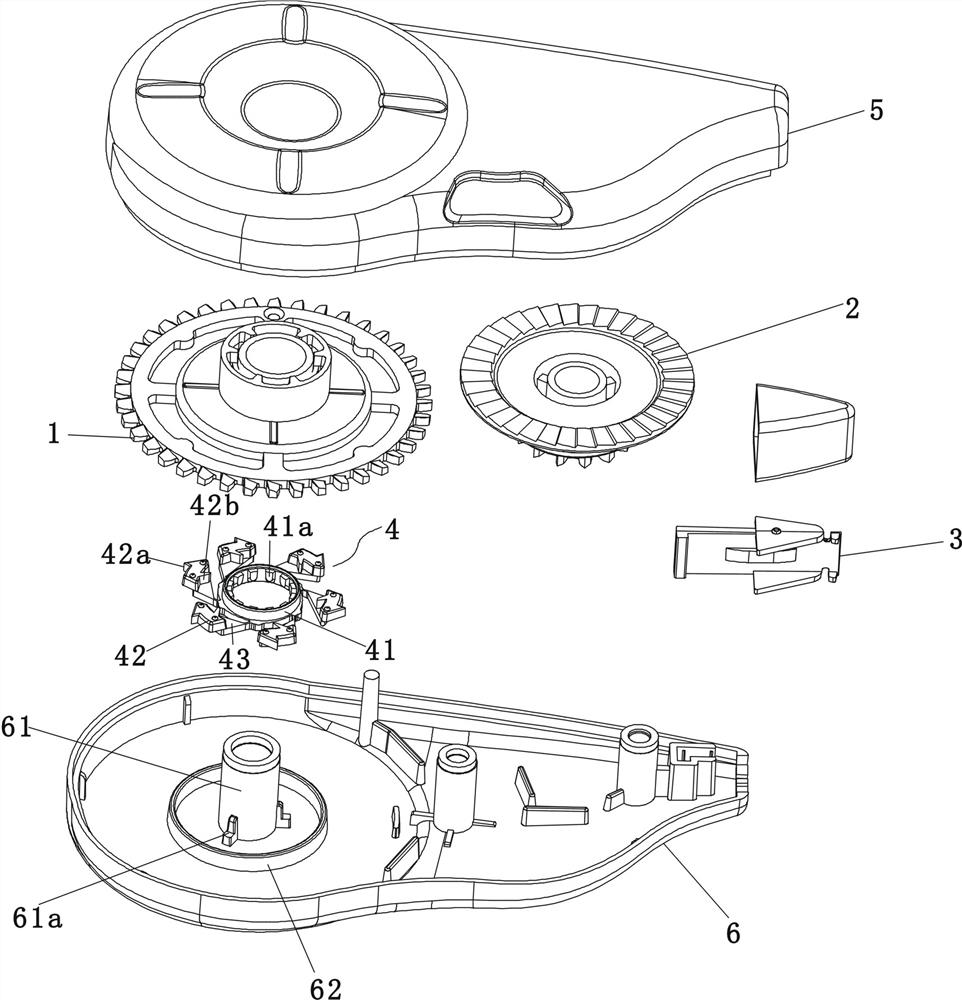

[0031] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in detail:

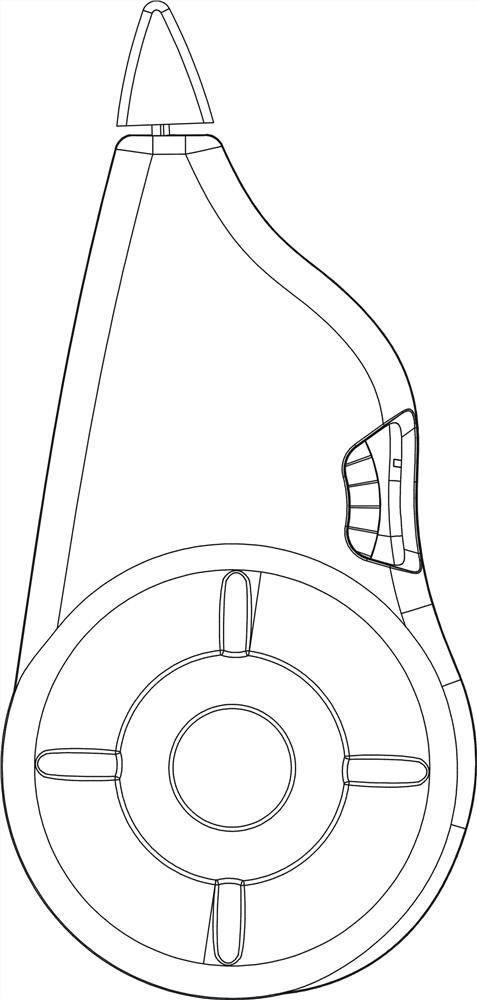

[0032] see figure 1 — Image 6 , the correction tape of this specific embodiment includes a feed pulley 1, a take-up pulley 2, a tongue 3, a swing member 4, an upper casing 5 and a lower casing 6; wherein the swing member 4 has a center ring 41, six Each swing head 42 is drawn out in an arc shape from the outside of the center ring 41 by six swing arms 43 respectively, and a second step is formed on the back of each swing head 42, and the outer claw 42 a and the inner claw 42 b are formed on a higher step; The inner side of the center ring 41 is formed with several teeth 41a; the same side of the feed pulley 1 has two concentric rings, which are divided into an inner ring 11 and an outer ring 12. A number of outer teeth e are formed on the outer side of the inner ring 11, and a number of teeth e are formed on the inner side of the outer ring 12. Inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com