Glass fiber reinforced polyester antiskid floor and preparation method thereof

A non-slip floor, polyester technology, applied in chemical instruments and methods, lamination, coating and other directions, can solve the problems of difficult to maintain the anti-slip effect, easy to damage the anti-slip structure, high cost of FRP floors, to expand the scope of application, Tightly combined, anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

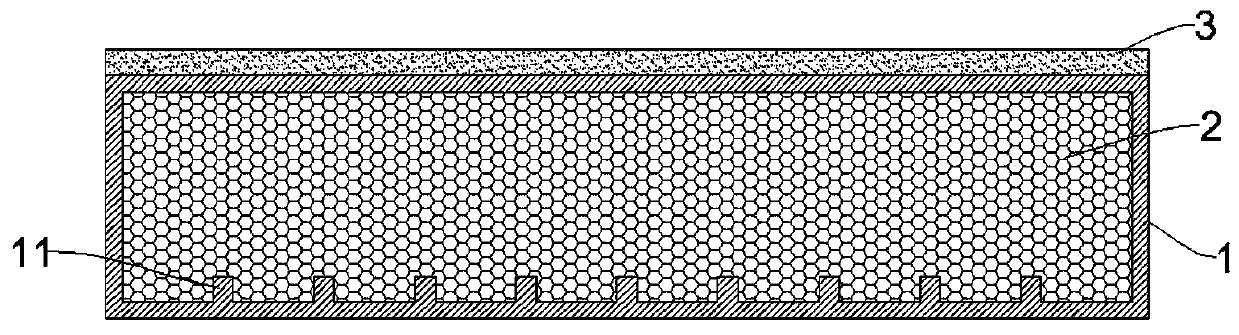

[0033] A kind of glass fiber reinforced polyester non-slip floor, such as figure 1 As shown, it includes a hollow FRP skeleton 1, a foam core layer 2 filled in the cavity of the FRP skeleton 1, and a surface layer 3 arranged on the upper surface of the FRP skeleton 1; the material of the FRP skeleton 1 is glass Fiber-reinforced polyester with a wall thickness of 2.5-3.0mm and a density of 1.4-2.1g / cm³. The inner wall of the FRP skeleton 1 is provided with several strip-shaped protrusions 11 integrally formed with the FRP skeleton (the protrusions 11 in this embodiment are set The bottom wall of the cavity of the FRP skeleton 1); the material of the foam core layer 2 is polyurethane; the components of the surface layer 3 include by weight: 20-25 parts of 40-60 mesh emery, 80-100 20-30 parts of purpose quartz sand, 15-20 parts of 300-330 mesh calcium carbonate, 25-35 parts of polyurea, 0.1-3 parts of toner; the thickness of surface layer 3 is 0.5-5mm.

[0034] The preparation m...

Embodiment 2

[0040] A kind of glass fiber reinforced polyester non-slip floor, such as figure 2 As shown, the basic structure is the same as that of Example 1, the difference is that in this embodiment, a number of grooves 12 are provided on the side surface where the FRP frame 1 and the surface layer 3 are bonded to improve the surface layer 3 and the FRP frame. 1 The firmness of the combination is more optimized. The protrusion 11 is arranged on the top wall of the cavity of the FRP frame 1 and corresponds to the upper and lower sides of the groove 12, so as to avoid the opening of the groove 12 and lower the position of the FRP frame 1. The wall thickness ensures that the strength of the FRP frame 1 is not affected.

Embodiment 3

[0042] A kind of glass fiber reinforced polyester non-slip floor, the structure is the same as that of Example 1, compared with Example 1, the process is optimized, that is, when the surface layer is coated in step S3, 3-6 parts are reserved, and the remaining polyurea Still mixing with emery, quartz sand, and calcium carbonate; coating the reserved polyurea on the upper surface of the FRP skeleton to form a pre-coating, and then quickly coating the mixed raw materials on the pre-coating; the rest Process step is with embodiment 1. The process described in this embodiment effectively improves the adhesion of the surface layer on the FRP skeleton and the compactness of the combination by pre-coating polyurea when the surface layer is coated.

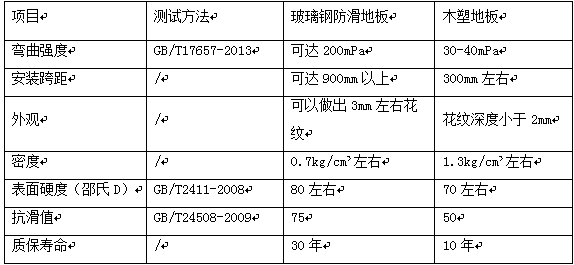

[0043] The performance comparison between the FRP anti-skid floor of the present invention and the conventional wood-plastic floor is shown in the following table:

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com