Wood grooving machine tool

A technology for grooving and machine tools, applied in the field of machine tools, can solve problems such as being unenvironmental, affecting the health of workers, and not being able to collect wood chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

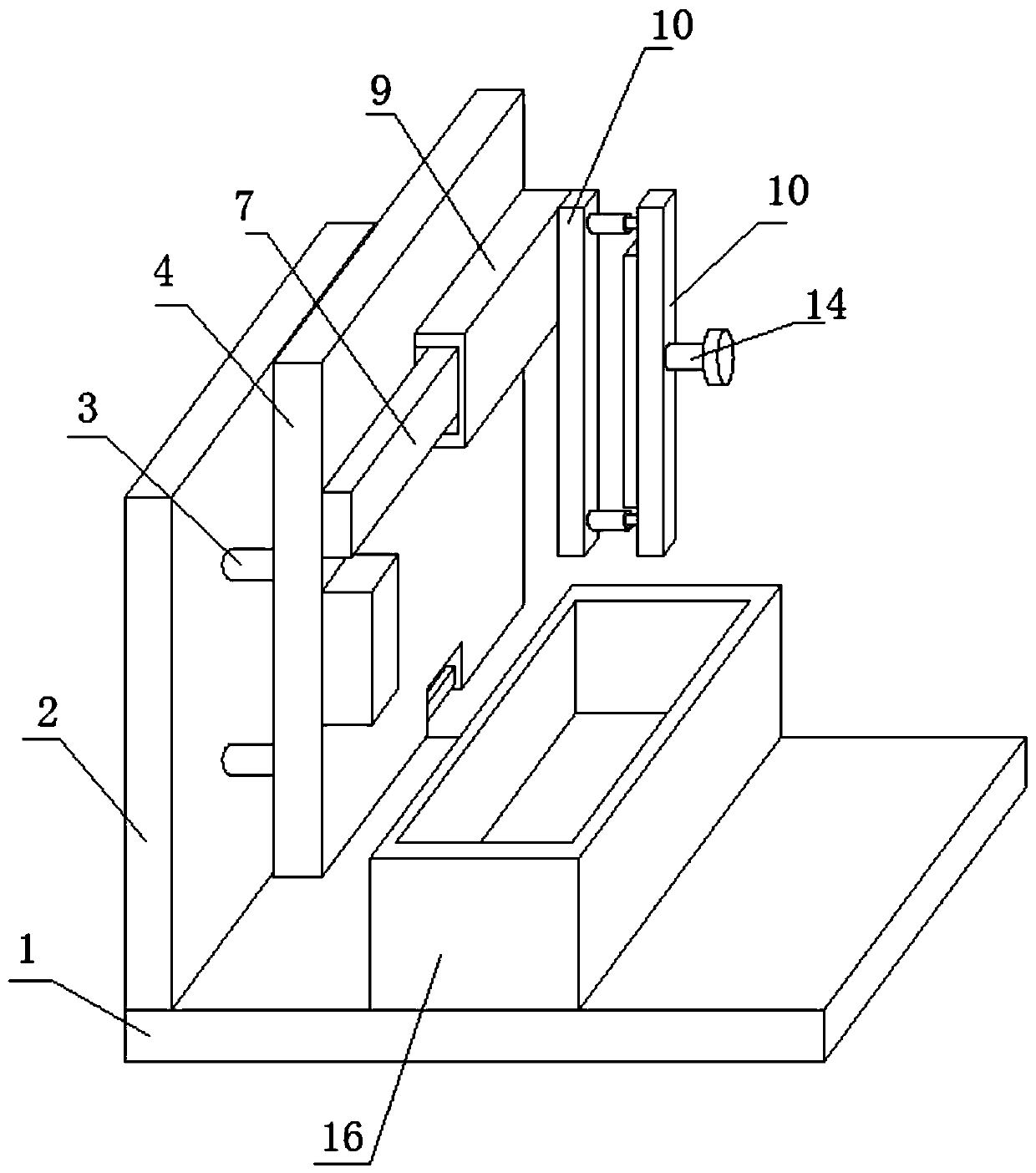

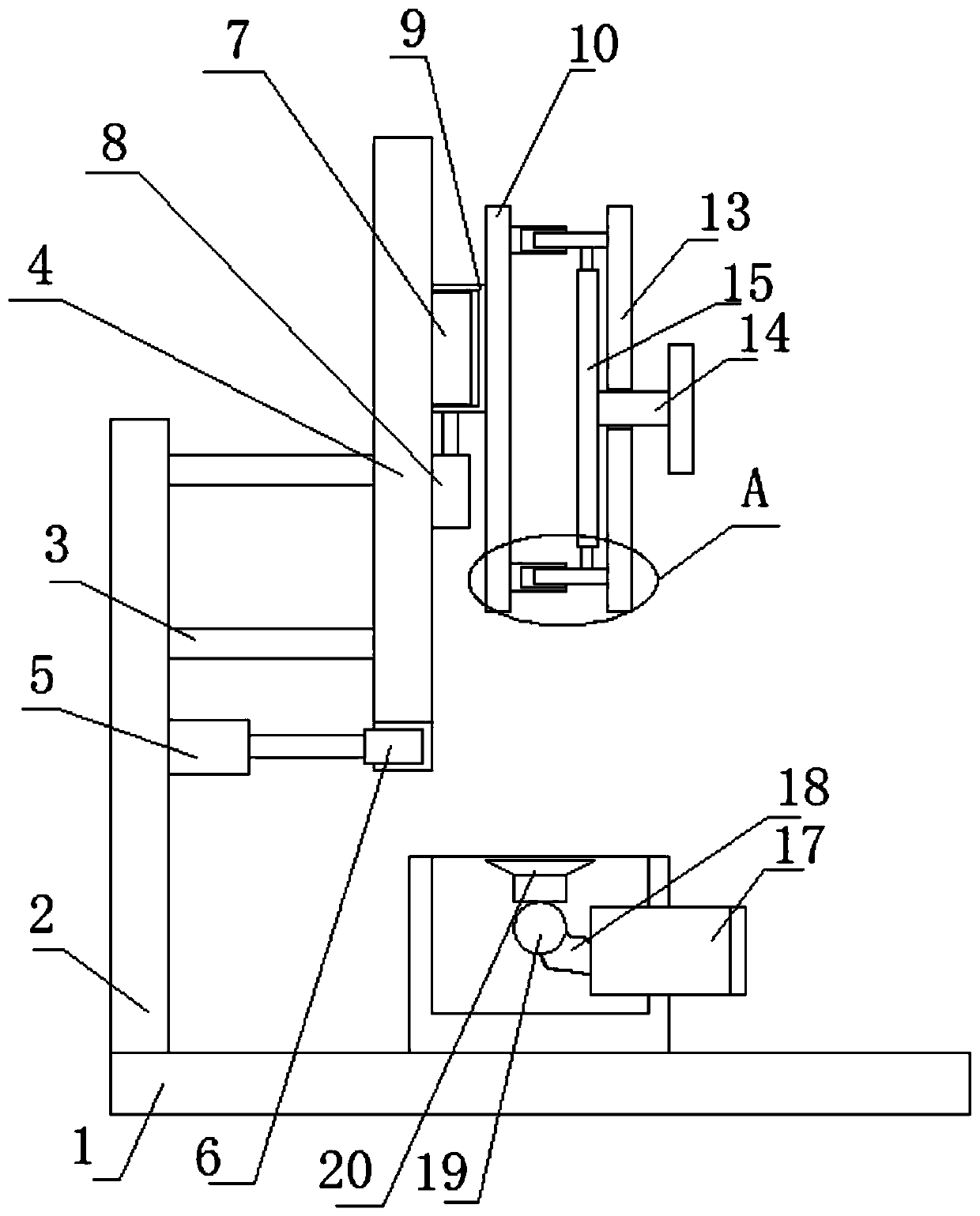

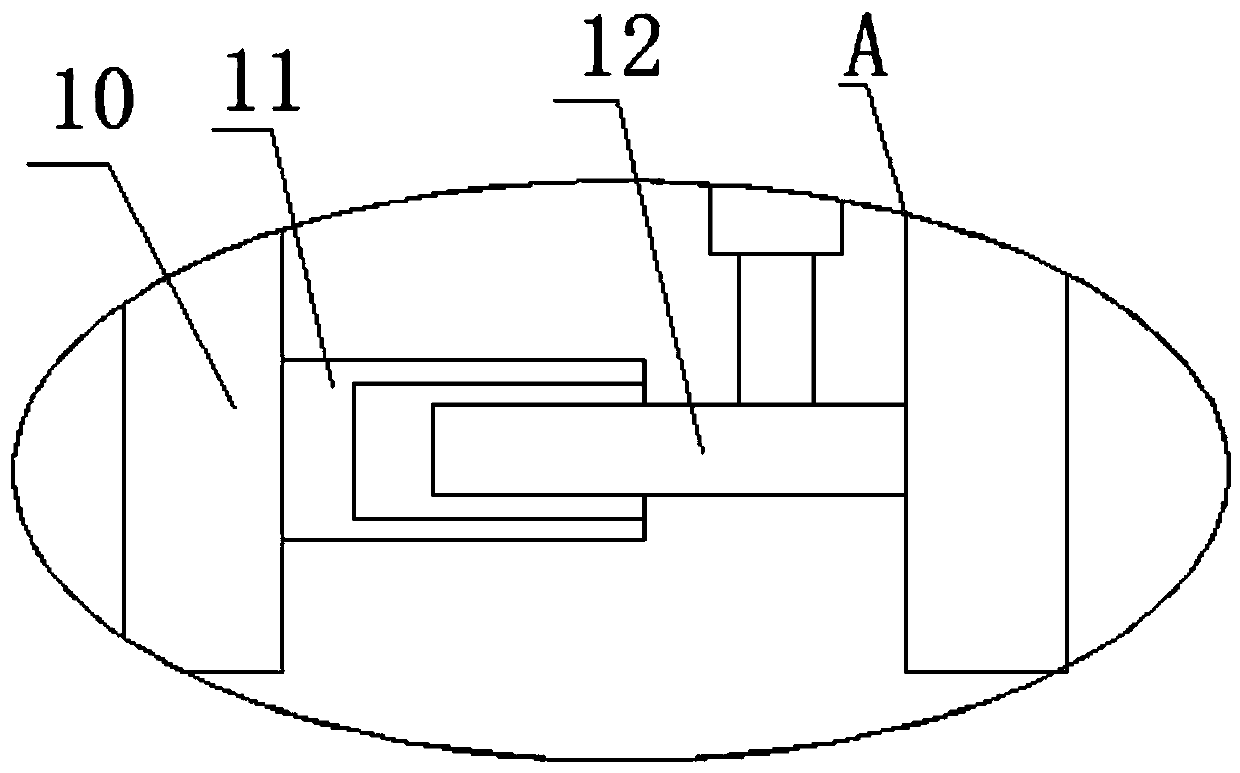

[0020] refer to Figure 1-3 , a wood grooving machine tool, comprising a base 1, a vertical plate 2 is fixedly mounted on one side of the top of the base 1, a mounting plate 4 is fixedly mounted on one side of the vertical plate 2, and a fixed plate 10 is slidably mounted on one side of the mounting plate 4 One side of the fixed plate 10 is slidingly installed with a moving plate 13, one side of the moving plate 13 is threadedly connected with a screw 14, and one end of the screw 14 is rotatably installed with a pressure plate 15, and the other end of the screw 14 runs through the bottom of the moving plate 13. One side extends to the other side of the moving plate 13, and the outer side of the screw rod 14 is screwed to the moving plate 13. The top center of the base 1 is fixed with a collection pool 16, and the inner wall of the collection pool 16 is provided with a sawdust collection assembly. And the collection pool 16 is located directly below the area between the moving ...

Embodiment 2

[0022] Make following further improvement on the basis of embodiment one:

[0023] In the present invention, in order to realize the grooving work of wood conveniently and quickly, one side of the vertical plate 2 is fixedly installed with a cylinder 5, and one end of the output shaft of the cylinder 5 is fixedly installed with a grooving knife 6, and one side of the grooving knife 6 runs through One side of the mounting plate 4 is also located on the same vertical plane as the other side of the mounting plate 4, and one side of the vertical plate 2 is fixedly equipped with a plurality of cross columns 3 arranged in a matrix, and the plurality of horizontal columns 3 are far away from the vertical plane of the vertical plate 2. One end is fixedly installed with one side of the mounting plate 4 .

[0024] In the present invention, in order to realize the lateral movement of the wood, one side of the mounting plate 4 is fixedly equipped with a slide rail 7, one side of the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com