Polishing device for machining stainless steel product

A polishing device, stainless steel technology, applied in the direction of manufacturing tools, grinding drive devices, metal processing equipment, etc., can solve the problems of weakening the electrolytic chemical polishing effect, small electrolyte flow area, slow electrolysis speed, etc., to improve the polishing effect, Accelerates the electrolysis effect and prevents leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

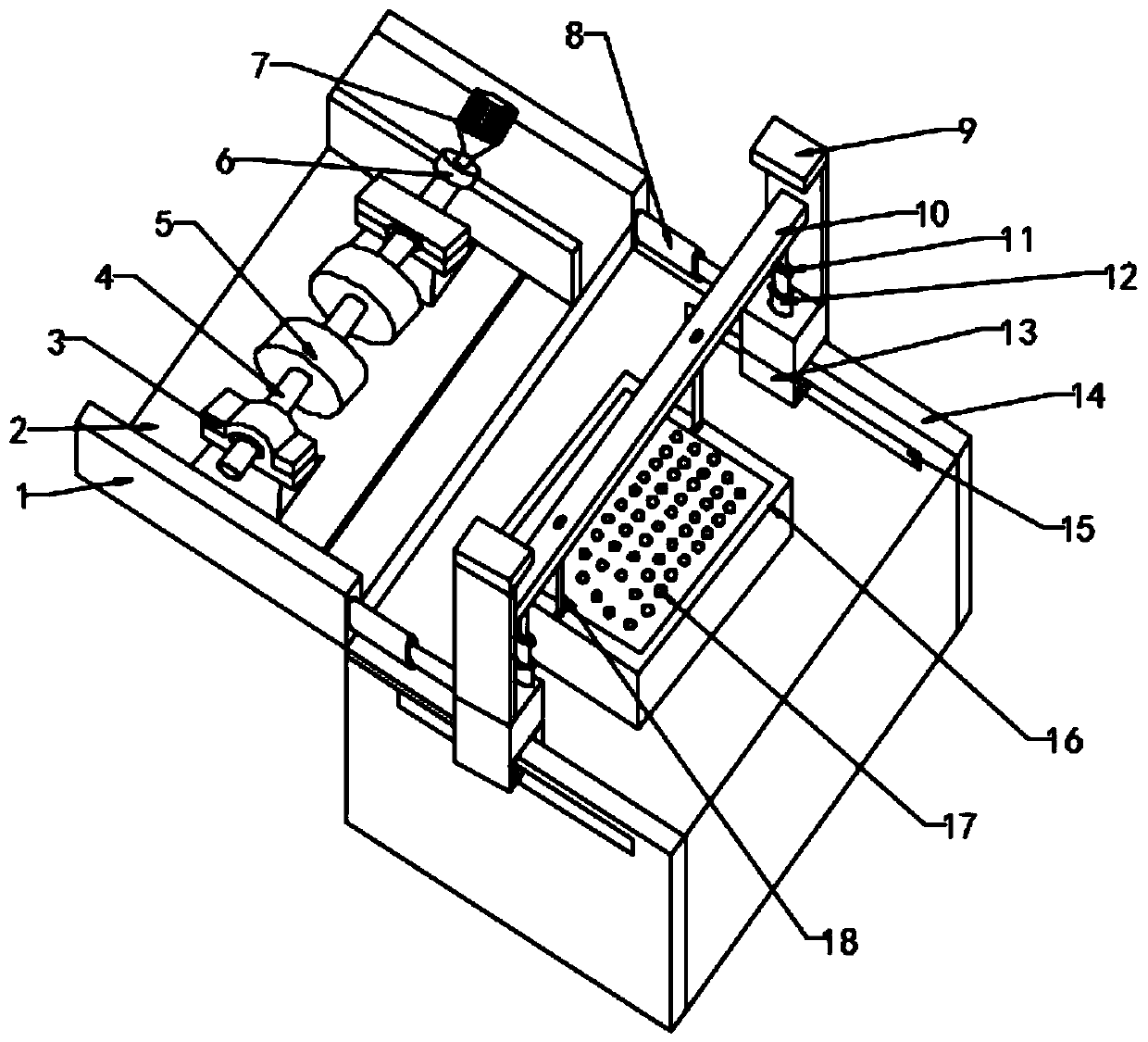

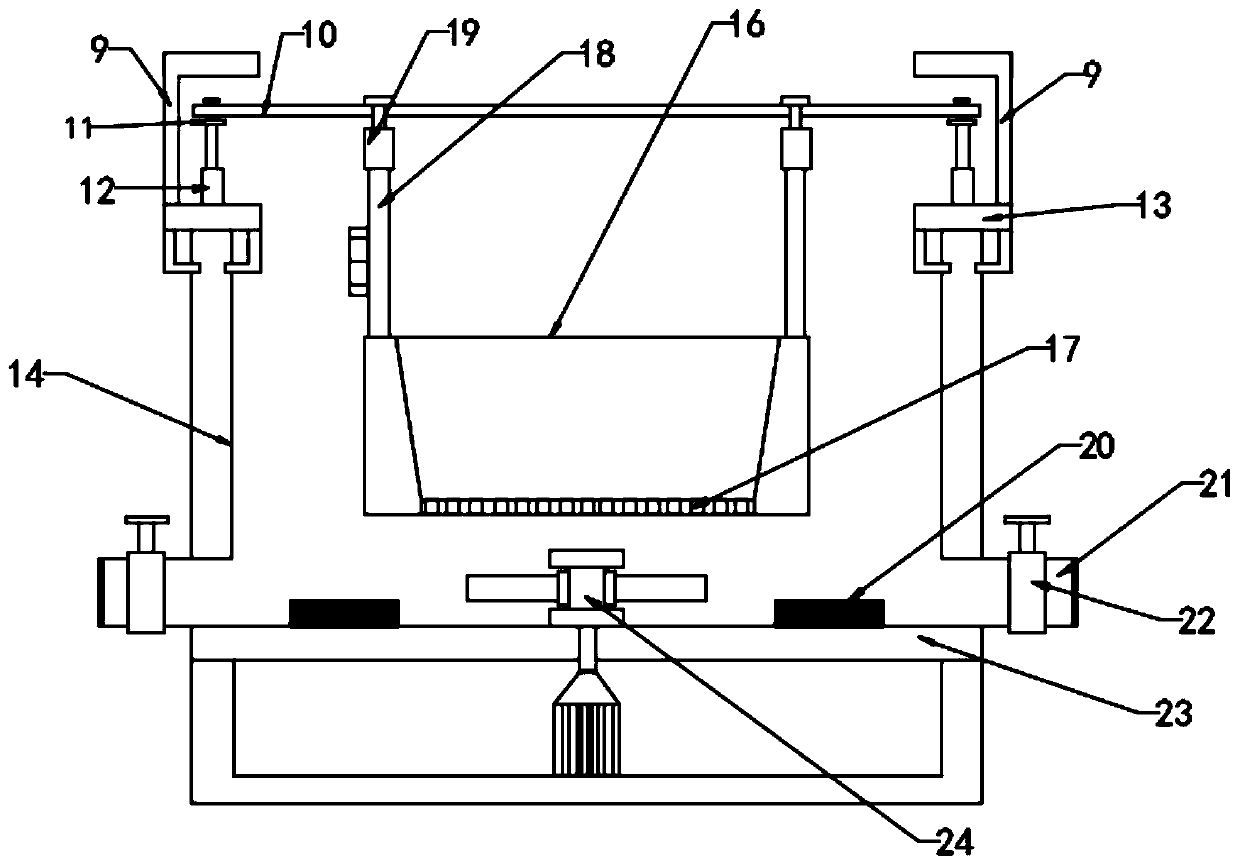

[0018] see figure 1 with figure 2 , in Embodiment 1 of the present invention, a polishing device for processing stainless steel products, which includes: a polishing table 2 and an electrolytic box 14, the electrolytic box 14 is arranged on one side of the polishing table 2, and a polishing assembly is installed on the polishing table 2; The inside of the electrolytic box 14 is provided with a soaking box 16, the lower end of the soaking box 16 is provided with a liquid inlet 17, and the left and right sides of the upper end of the soaking box 16 are provided with electrolytic rods 18, which are positive electrolytic rods; the upper end of the electrolytic rod 18 is installed on Inside the installation terminal 19, the installation terminal 19 is arranged at the lower end of the movable plate 10;

[0019] The left and right sides of the movable plate 10 are installed on the supporting plate 11, the second electric telescopic rod 12 is installed on the lower end of the suppor...

Embodiment 2

[0026] Further, the inner wall of the electrolytic box 14 is provided with a limiting groove 15, the slider 13 is in the shape of "Π", and the protrusion at the lower end of the slider 13 is stuck in the limiting groove 15 on the inner wall of the electrolytic box 14. Through this structural design, Slider 13 is not prone to position deviation when sliding and displacing at the upper end of electrolytic box 14 , and when the second electric telescopic rod 12 at the upper end of slider 13 moves, slider 13 is not easy to be disengaged from electrolytic box 14 due to uneven force.

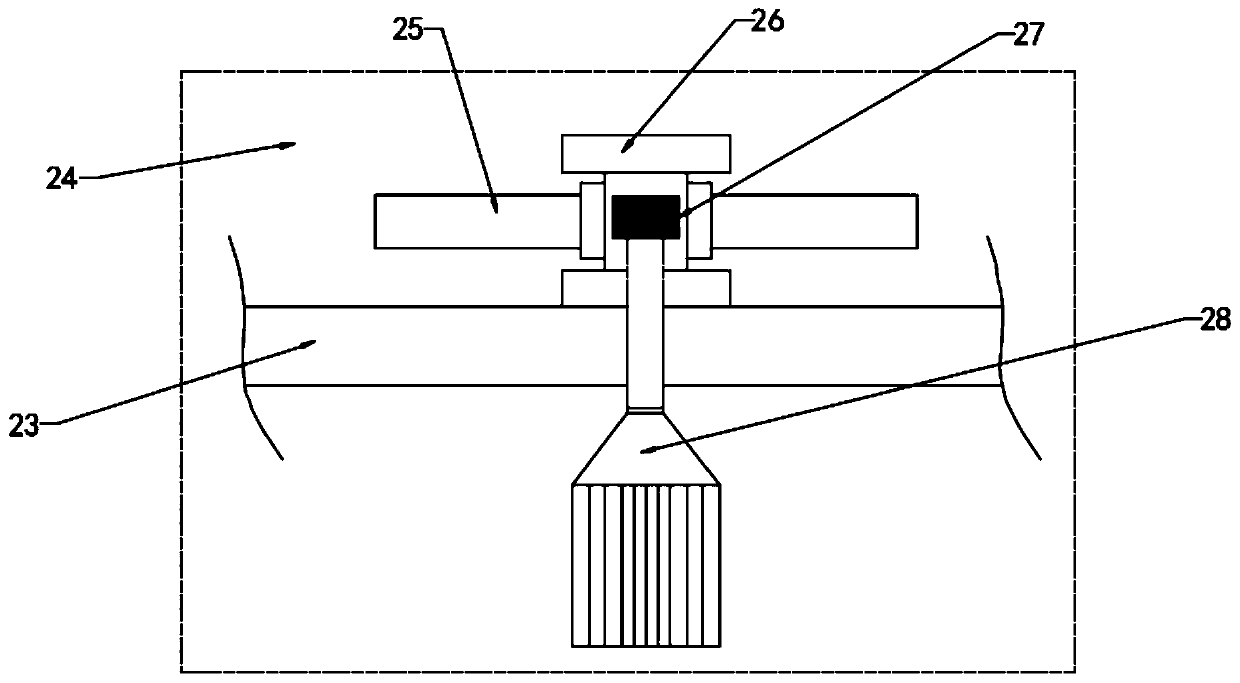

[0027] see image 3 , further, the stirring assembly 24 includes a permanent magnet block 25, a sleeve and a second motor 28, the permanent magnet block 25 and the sleeve are made of non-metallic materials; the permanent magnet block 25 is movably installed on the sleeve, and the sleeve The upper end is provided with a limit block 26; the inside of the sleeve is provided with an electromagnetic block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com