Anti-tool-collision digital controlled lathe

A numerical control lathe and anti-collision technology, applied in the field of machine tools, can solve the problems of collision accident, high risk factor, failure of module grinding, etc., and achieve the effect of reducing harmfulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

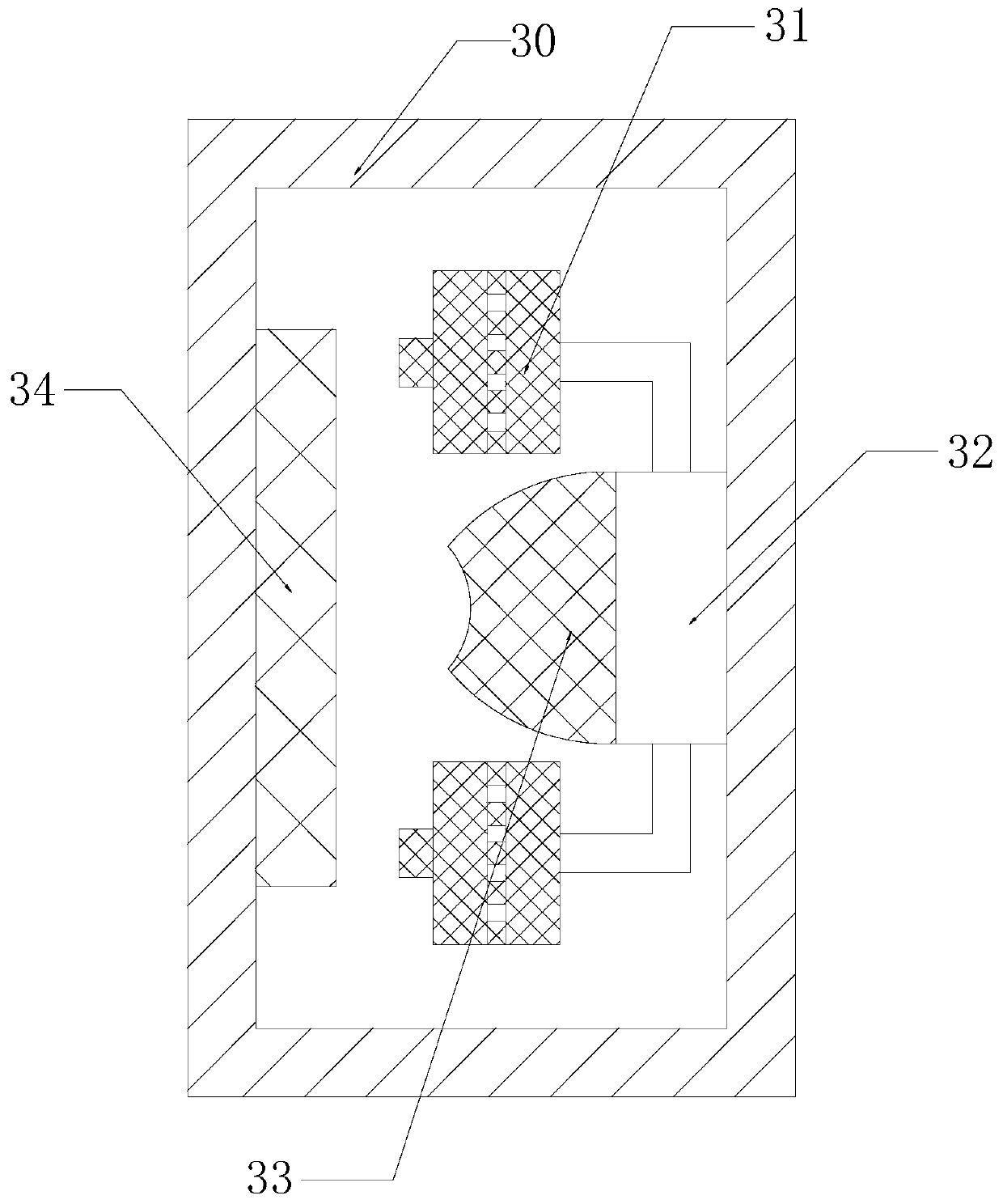

[0028] see Figure 1-Figure 5 , a kind of anti-collision knife numerical control lathe, the present invention provides a kind of anti-collision knife numerical control lathe, aiming at the deficiencies in the prior art, the present invention is realized through the following technical scheme: a kind of anti-collision knife numerical control lathe, its structure includes machine body 1. Sliding door 2, processing box 3, control box 4, base 5, the body 1 is slidably connected with the sliding door 2, the body 1 is mechanically connected with the processing box 3, and the base 5 is installed below the body 1. The right side of the body 1 is provided with a control box 4;

[0029] Described processing box 3 is provided with casing 30, catapult 31, knife rest clamp 32, bumper 33, module folder 34, and the left side of described casing 30 is provided with knife rest clamp 32, and described catapult 31 installs On both sides of the tool post clamp 32, the module clamp 34 is installe...

Embodiment 2

[0038] see Figure 1-Figure 5 , a kind of anti-collision knife numerical control lathe, the present invention provides a kind of anti-collision knife numerical control lathe, aiming at the deficiencies in the prior art, the present invention is realized through the following technical scheme: a kind of anti-collision knife numerical control lathe, its structure includes machine body 1. Sliding door 2, processing box 3, control box 4, base 5, the body 1 is slidably connected with the sliding door 2, the body 1 is mechanically connected with the processing box 3, and the base 5 is installed below the body 1. The right side of the body 1 is provided with a control box 4;

[0039] Described processing box 3 is provided with casing 30, catapult 31, knife rest clamp 32, bumper 33, module folder 34, and the left side of described casing 30 is provided with knife rest clamp 32, and described catapult 31 installs On both sides of the tool post clamp 32, the module clamp 34 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com