An environment-friendly rotary automatic coating device and coating process

A rotary and coating technology, which is applied to the surface coating liquid device, spray device, coating, etc., can solve the problems of excessive spraying of paint, difficult cleaning of paint, and waste of paint, so as to reduce the difficulty of cleaning and reduce the The effect of reducing paint waste and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

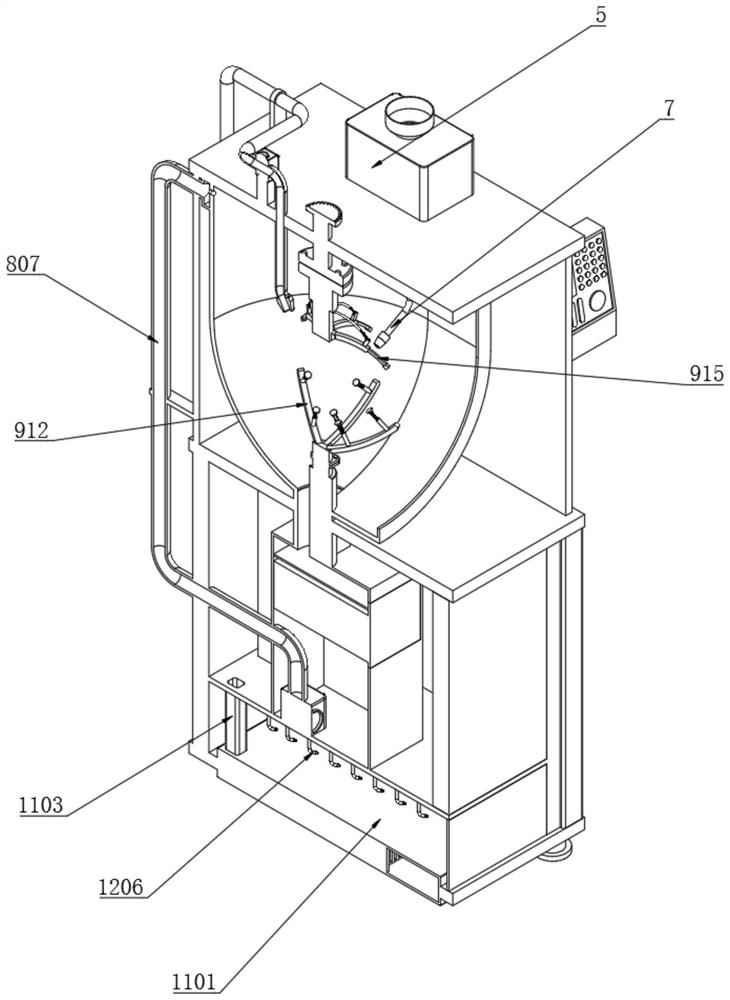

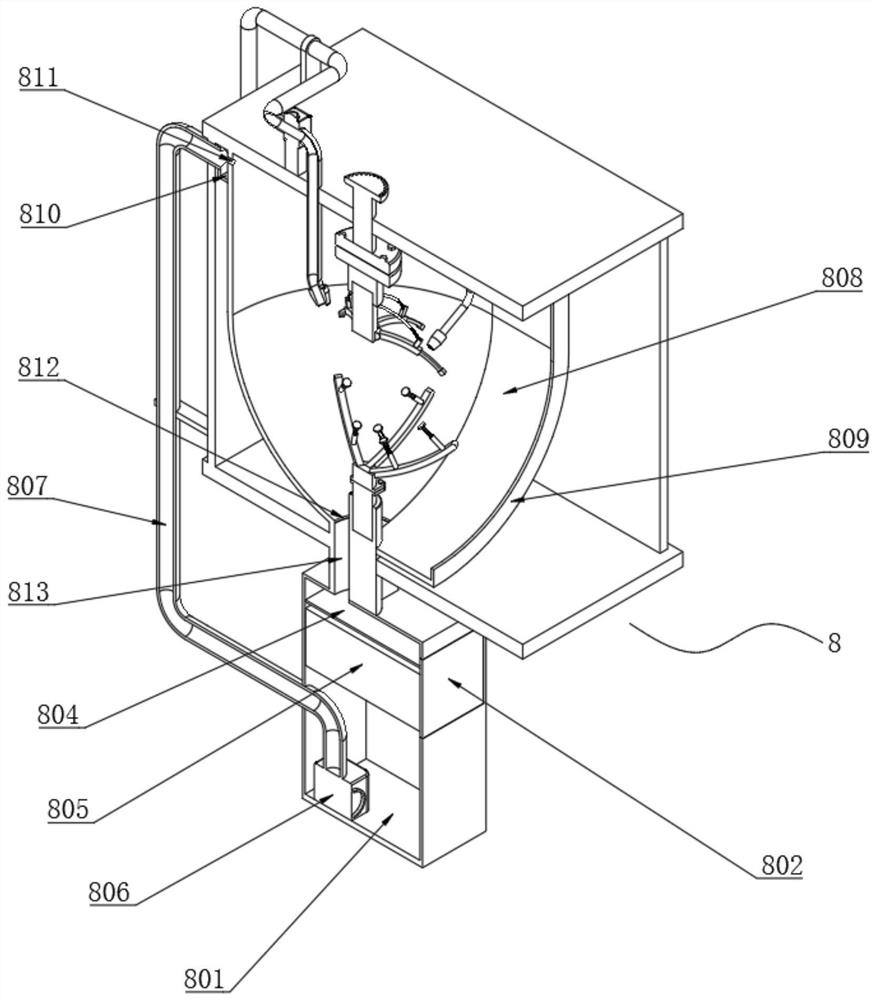

[0060] Example: such as Figure 1-15 As shown, the present invention provides a technical solution, an environment-friendly rotary automatic coating device, comprising a painting bottom box 1, a painting cabin 2 is fixedly installed on the top of the coating bottom box 1, and one end of the coating cabin 2 is connected with a The control panel 3, the other end of the painting chamber 2 is rotatably installed with an observation window 4, the top of the painting chamber 2 is fixedly connected to the spraying chamber 5, the top of the spraying chamber 5 is fixedly connected to the paint adding chamber 6, and the bottom of the spraying chamber 5 Fixedly connected with spray pipe 7;

[0061] An anti-adhesion filter mechanism 8 is installed inside the coating bottom box 1 and the coating warehouse 2, and the anti-adhesion filter mechanism 8 includes a filter warehouse 801, a dismounting plate 802, a sliding seat 803, a reverse osmosis net 804, a filter powder bag 805, Delivery pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com