Fire extinguishing steam control method, device, equipment and storage medium for medium-speed coal pulverizer

A control method and technology for coal mills, which are applied in fire rescue, grain processing, etc., can solve problems such as equipment damage, medium-speed coal mill skipping, and difficulty in extinguishing steam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

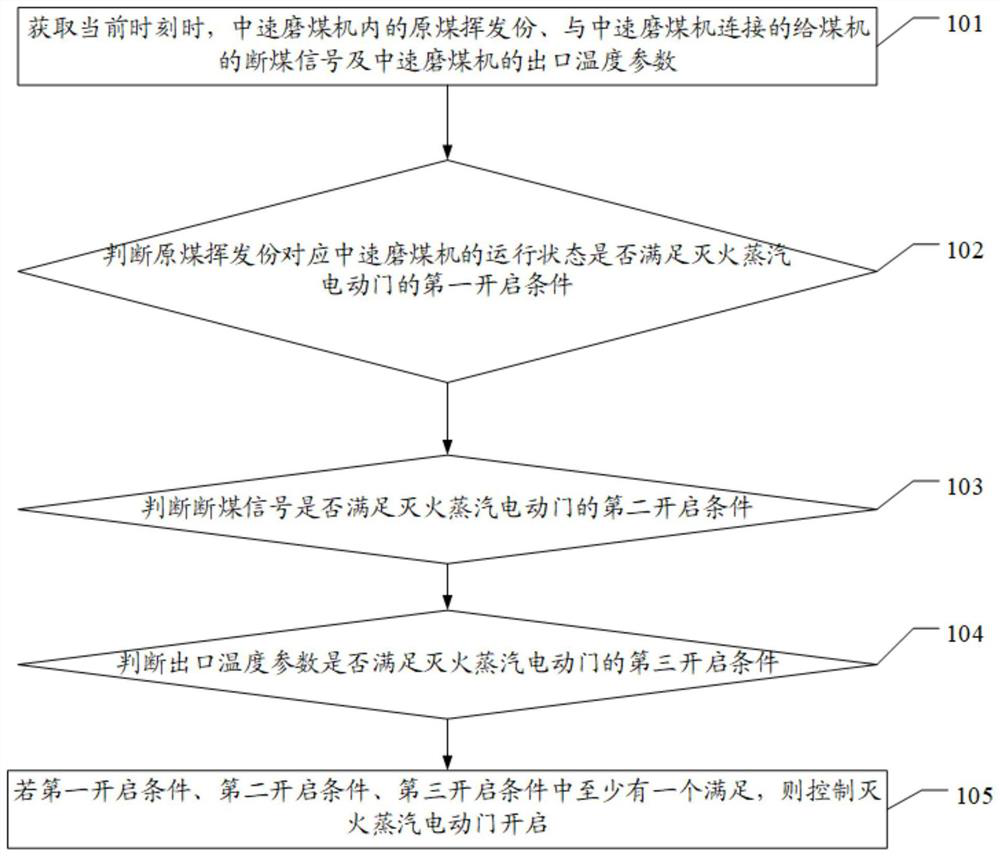

no. 1 example

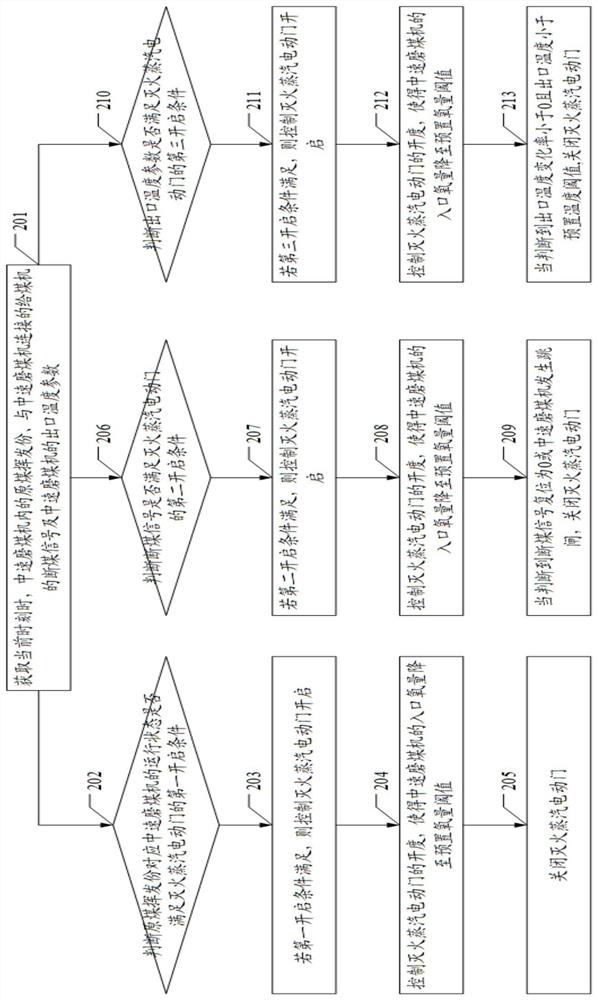

[0056] The above is the first embodiment of the fire extinguishing steam control method of a medium-speed coal mill provided in the embodiment of the present application, and the following is the second implementation of the fire extinguishing steam control method of a medium-speed coal mill provided in the embodiment of the present application example.

[0057] see figure 2 , a schematic flow chart of the second embodiment of a fire extinguishing steam control method for a medium-speed coal mill in the embodiment of the present application, including:

[0058] Step 201: At the current moment, the volatile content of raw coal in the medium-speed coal mill, the coal cut-off signal of the coal feeder connected to the medium-speed coal mill, and the outlet temperature parameters of the medium-speed coal mill are obtained.

[0059] It should be noted that the content of step 201 is the same as that of step 101 in the first embodiment, and will not be repeated here.

[0060] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com