Ore fertilizer soil manufacture device

A technology for manufacturing equipment and fertilizers, which is applied in the field of ore fertilizer soil manufacturing equipment, can solve problems such as lack, and achieve the effects of improving air permeability, improving utilization rate, and benefiting plant rooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

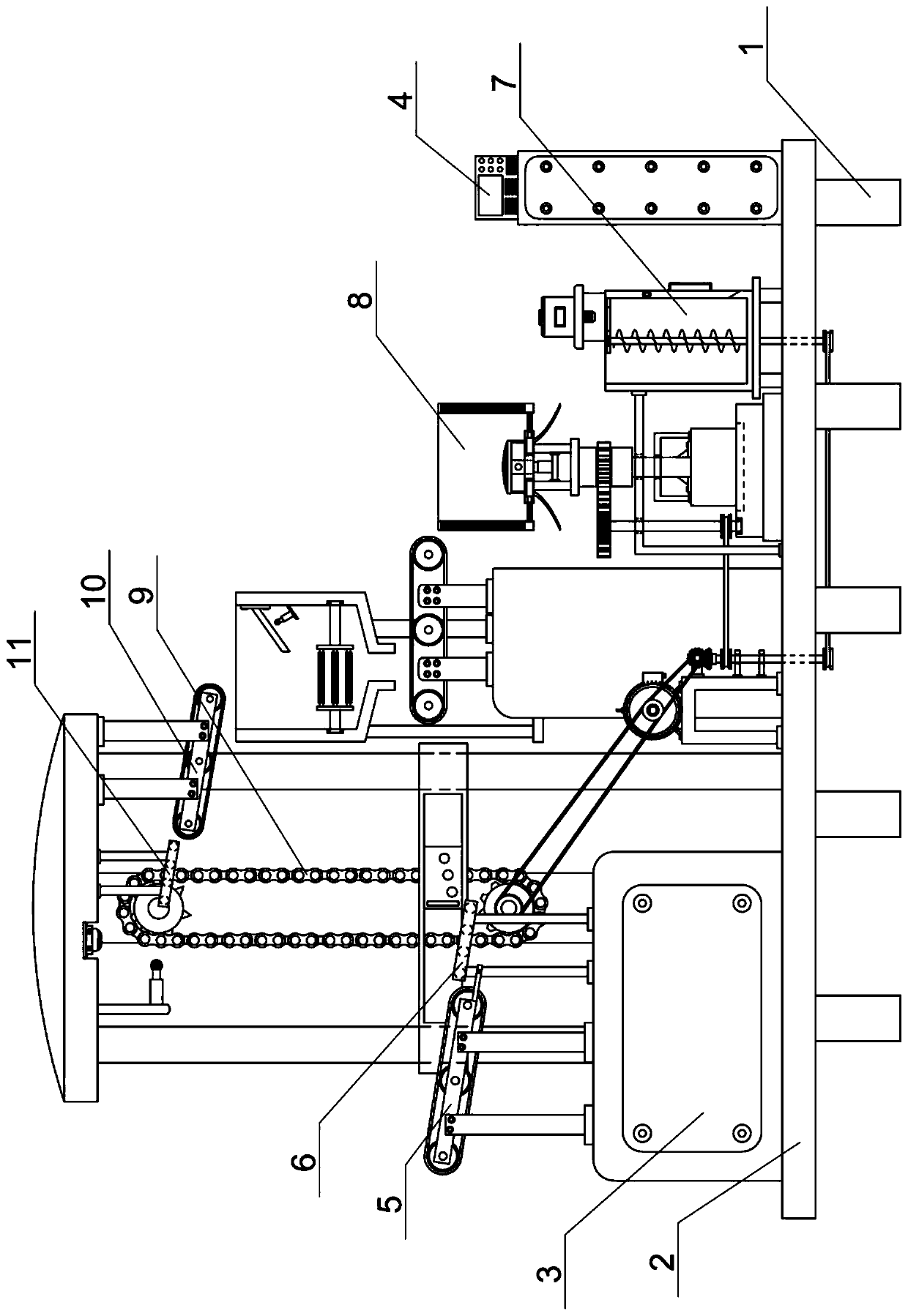

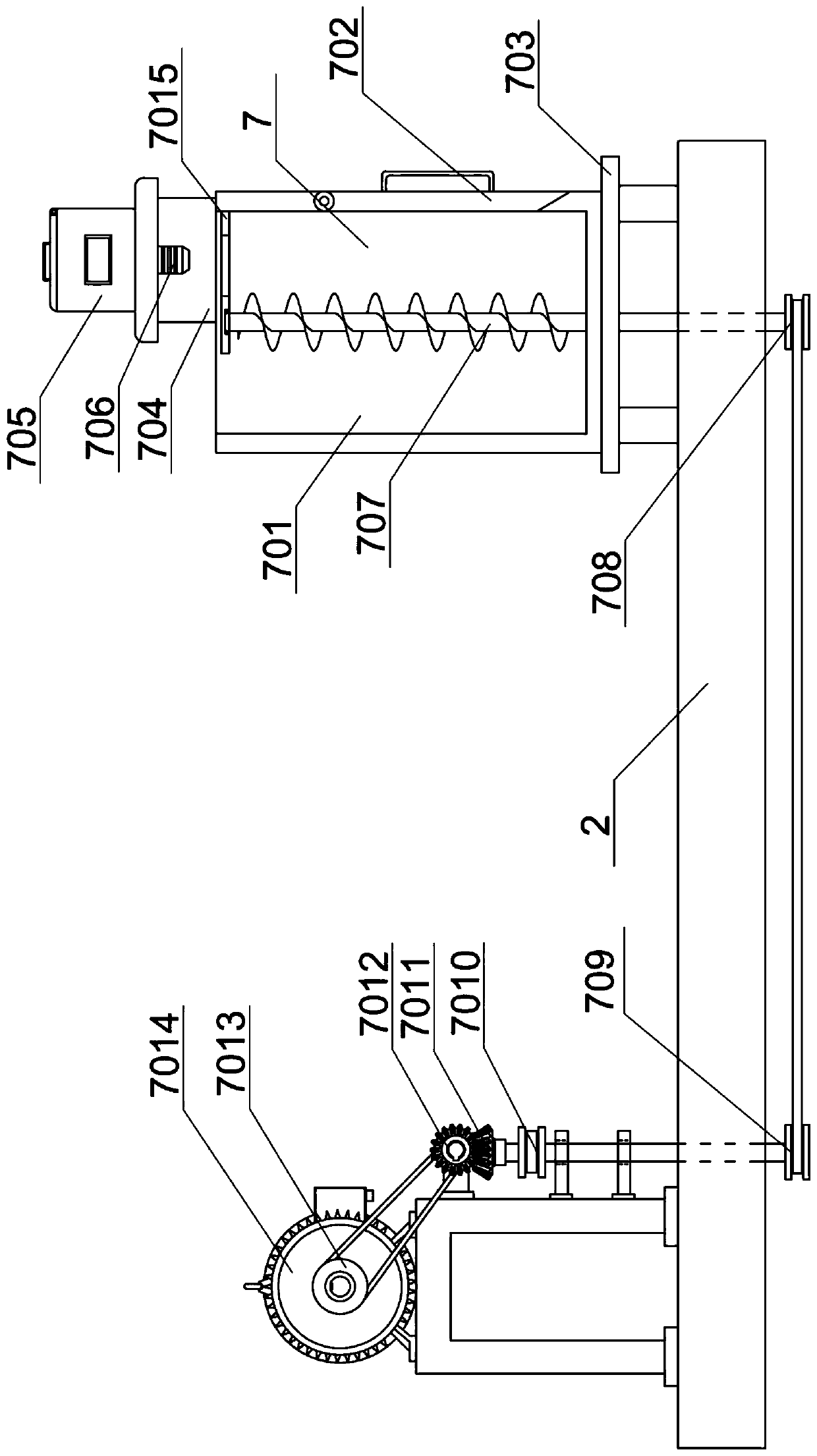

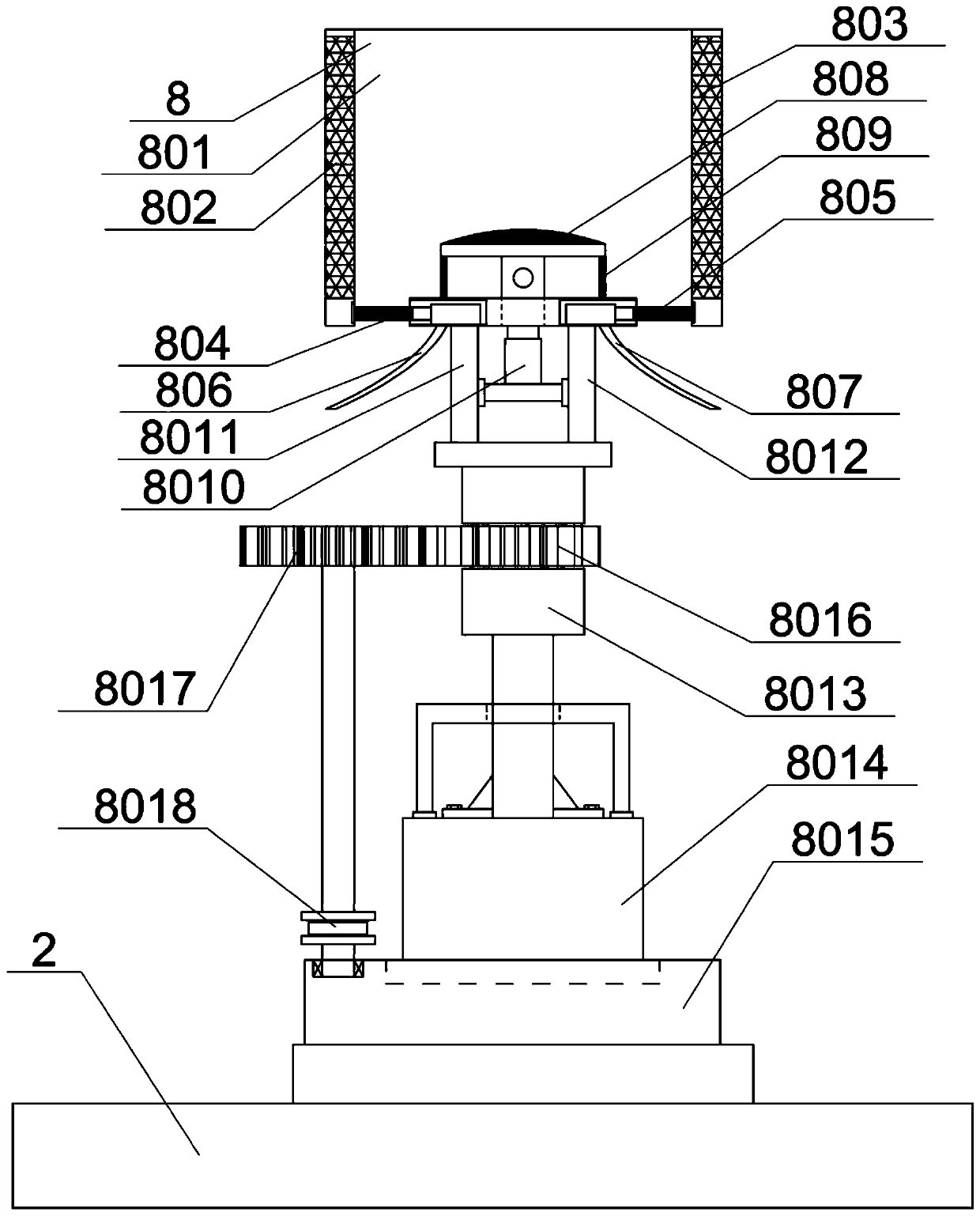

[0029] An ore fertilizer soil manufacturing device, such as Figure 1-6 As shown, it includes a support foot 1, a bottom plate 2, a cushion block 3, a control panel 4, a first conveyor belt 5, a first four-roll grid plate 6, a fertilizer making device 7, a potash fertilizer external introduction device 8, a splitting device 9, and a second Conveyor belt 10 and second four-roll grid plate 11; the top of support leg 1 is welded to bottom plate 2; the left front side of the top middle of bottom plate 2 is bolted to cushion block 3; the right front side of the top middle of bottom plate 2 is connected to control panel 4 through a strut The right side of the top middle part of the bottom plate 2 is provided with a fertilizer making device 7; the bottom right side of the top middle part of the bottom plate 2 is provided with a potash fertilizer external introduction device 8, and the left bottom of the potash fertilizer external introduction device 8 is connected with the fertilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com