Vibrating screen intelligent cleaning system

An intelligent cleaning system and vibrating screen technology, applied in the direction of mobile filter element filter, separation method, filtration separation, etc., can solve the problems of manual operation, time-consuming and laborious environmental pollution, etc., and achieve simple installation, reduce water consumption, and ensure cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

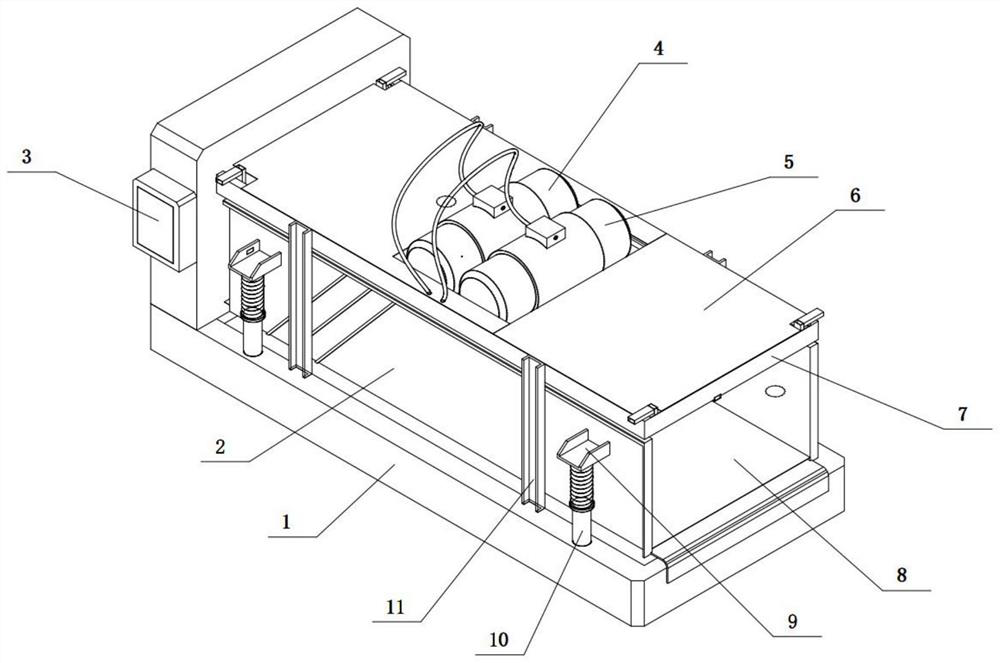

[0021] Combine below Figure 1-3 This embodiment is described. The present invention relates to the field of vibrating screen treatment, more specifically, an intelligent cleaning system for vibrating screens, including a base 1, a screen box 2, a rectangular top frame 7, a screen 8, a convex seat 9, a vertical sleeve 10, Support rod 11, rectangular bottom frame 12, door-shaped support beam 13, hook 14, nozzle I19, air pipe 20, nozzle II21 and liquid pipe 22, the present invention adopts the gas-liquid two-phase cleaning method to ensure the cleaning effect and greatly reduce the water consumption , does not affect the performance of drilling fluid.

[0022] The front and rear sides of the rectangular top frame 7 are fixedly connected with two support rods 11, and the four support rods 11 are fixedly connected on the upper side of the base 1, and the bottom of the screen box 2 is provided with a screen 8, and the bottom of the screen box 2 The upper side, left side and right ...

specific Embodiment approach 2

[0026] Combine below Figure 1-3 To illustrate this embodiment, the vibrating screen intelligent cleaning system further includes a top cover 6 , and the top covers 6 are provided on the left and right sides of the base 1 .

specific Embodiment approach 3

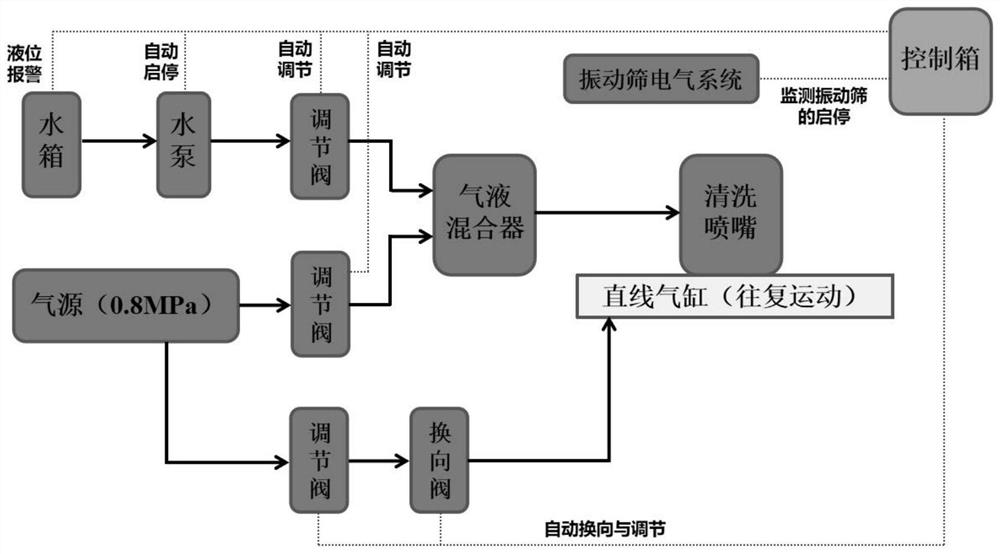

[0027] Combine below Figure 1-3 To illustrate this embodiment, the vibrating screen intelligent cleaning system also includes a control box 3, an air pump 4 and a water pump 5, the left part of the base 1 is provided with a control box 3, and the middle part of the rectangular top frame 7 is fixedly connected with an air pump 4 and a water pump 5, The air pump 4 is connected to the air pipe 20 through a flexible pipe, and the water pump 5 is connected to the liquid pipe 22 through a flexible pipe. The air pump 4 and the water pump 5 pass gas into the air pipe 20 and water into the liquid pipe 22 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com