Micro-joint type grating pinch plate, combined array and production method of micro-joint type grating pinch plate

A pinch plate and grating technology, applied in the direction of diffraction grating, optics, optical components, etc., can solve problems such as deviation of grating cylinder mirror line effect, prevent color change, improve integrity and accuracy of splicing effect, and reduce pre-investment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

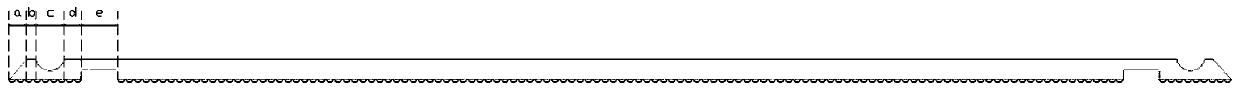

[0029] Such as Figure 1-6 The manufacturing method of the micro-seamed grating gusset shown is made through the following steps:

[0030] (1) Panel production: such as figure 1 As shown, firstly, the thickness is 3-5mm, the line density is 30-50 lines / inch, and the area is 0.5-1.5m 2 Conventional PS or PP material rectangular grating plate (keep two as much as possible), through the existing technology, pre-print the printing layer on the upper surface with ordinary UV ink or heat-resistant UV ink, and make the lenticular grating area on the lower surface , forming a rectangular grating plate with a 3D light and shadow effect that the viewer can feel through the observation of the lower surface; on a pair of opposite edges of the rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com