Shifting fork switching mechanism for clutch of washing machine

A switching mechanism and clutch technology, which is applied to other washing machines, applications, washing devices, etc., can solve the problems of inability to accurately control the switching dehydration conditions, easy entanglement of clothes, and inability to accurately control the rotation angle of the fork.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

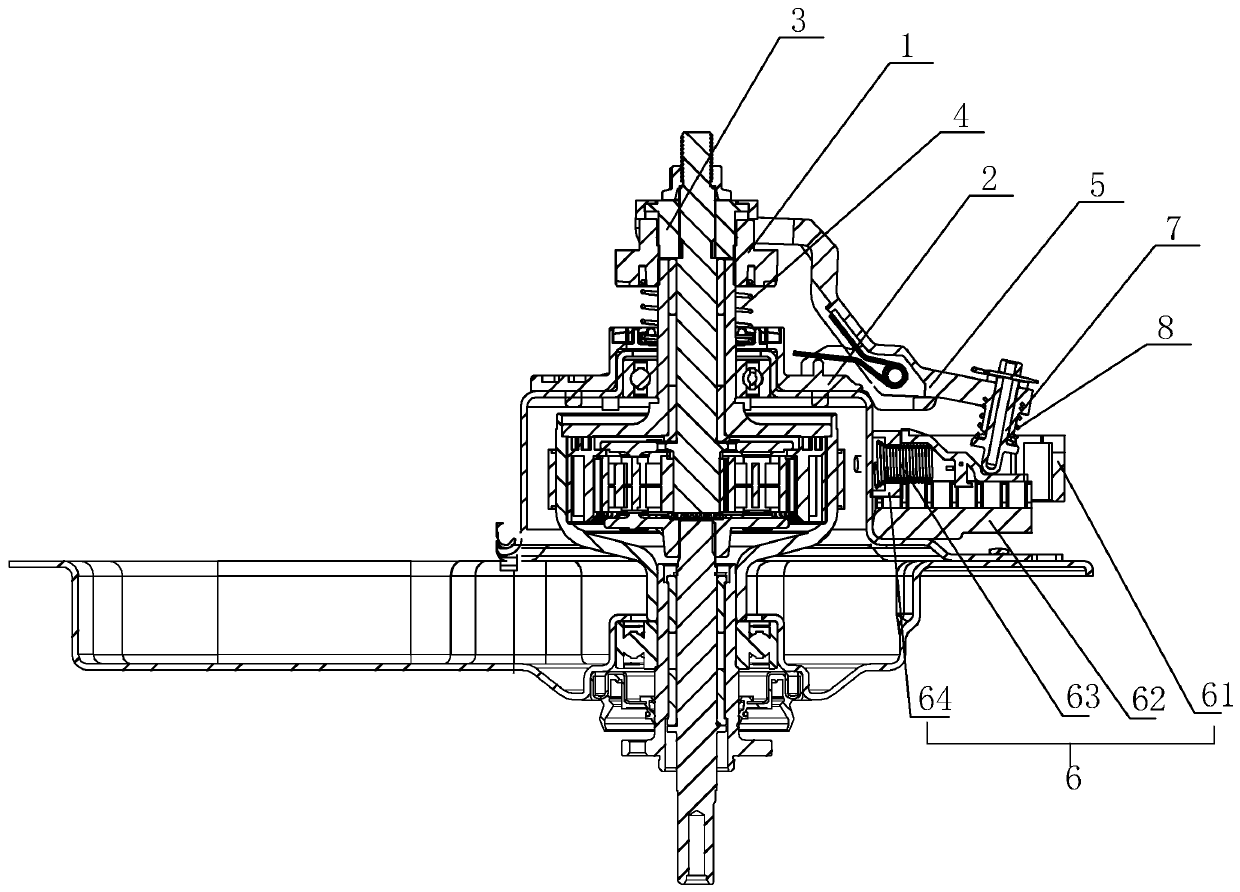

[0027] Refer to attached Figure 1 to Figure 8 A shift fork switching mechanism used for a clutch of a washing machine according to the present invention will be further described in detail.

[0028] A shift fork conversion mechanism for washing machine clutches, including a coupling disc 1, a positioning disc 2 and a torque transmission sleeve 3, a clutch spring 4 is arranged between the coupling disc 1 and the positioning disc 2, and the clutch spring 4 drives the coupling disc 1 Cooperate with the torque transmission sleeve 3;

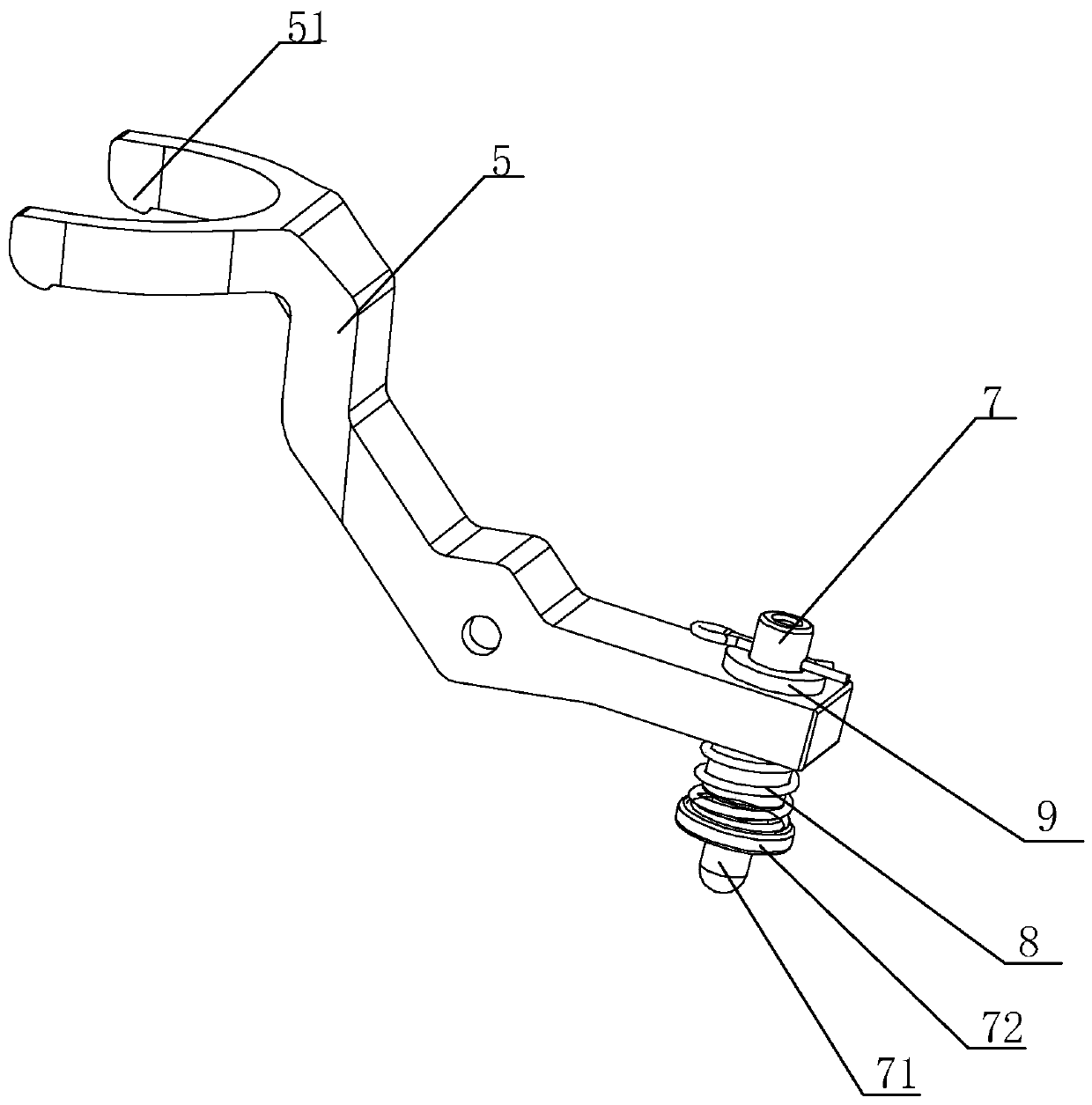

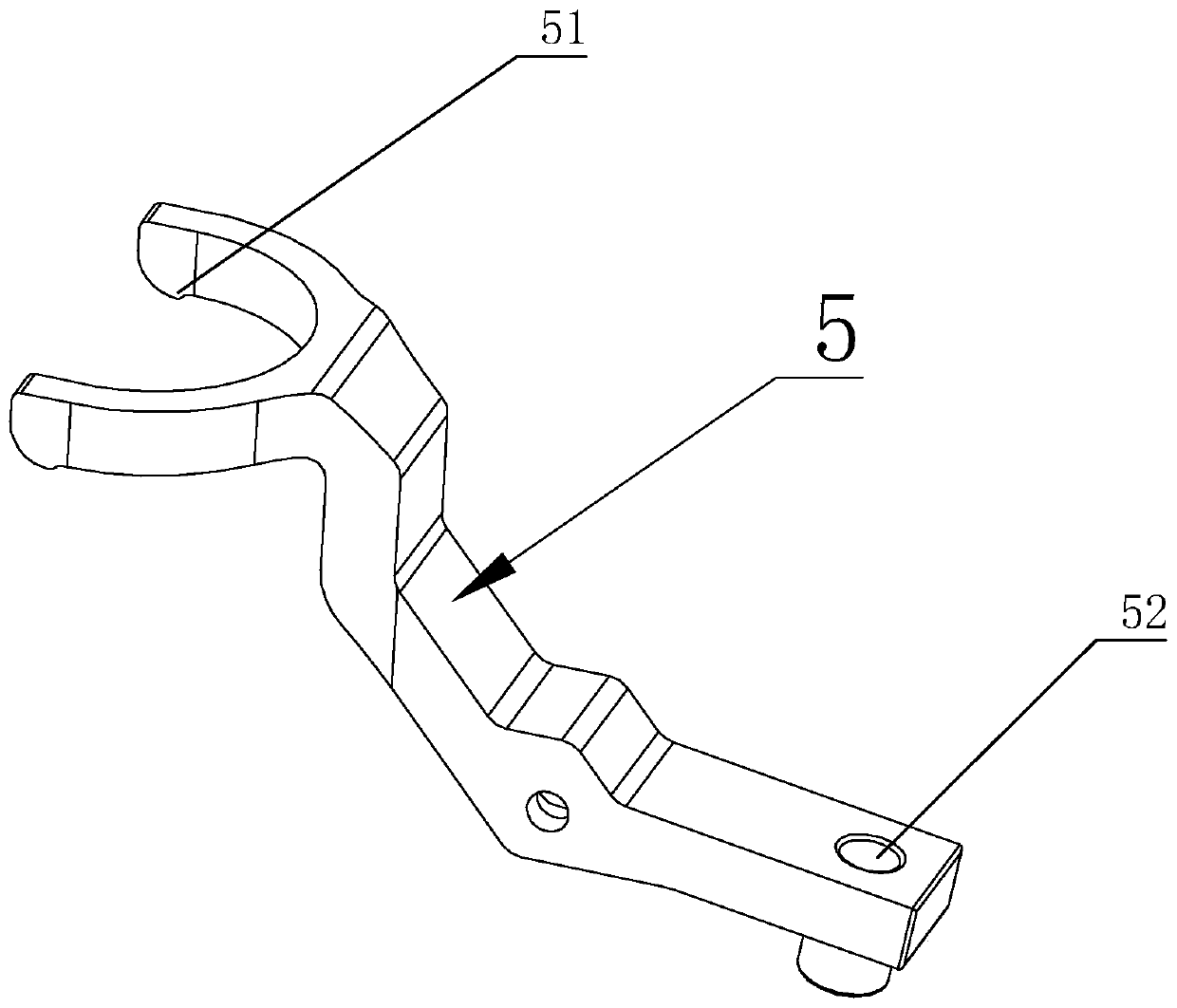

[0029] The shift fork conversion mechanism also includes a shift fork 5 that is arranged on the positioning plate 2 and a shift fork driving device 6 that drives the shift fork 5 to rotate. One end of the shift fork 5 is provided with a boss 51, and the boss 51 is in contact with the connecting plate 1; the other end of the shift fork 5 is provided with a linkage hole 52, and a push rod 7 and a push rod spring 8 are arranged in the linkage hole 52,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com