Binding machine

A technology for a bundling machine and bundling wire, which is applied to bundling objects, bundling materials, and parts of bundling machinery, etc., can solve the problems of easy entanglement of bundling wires, poor delivery of bundling wires, detachment of bundling wires, etc. Poor delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

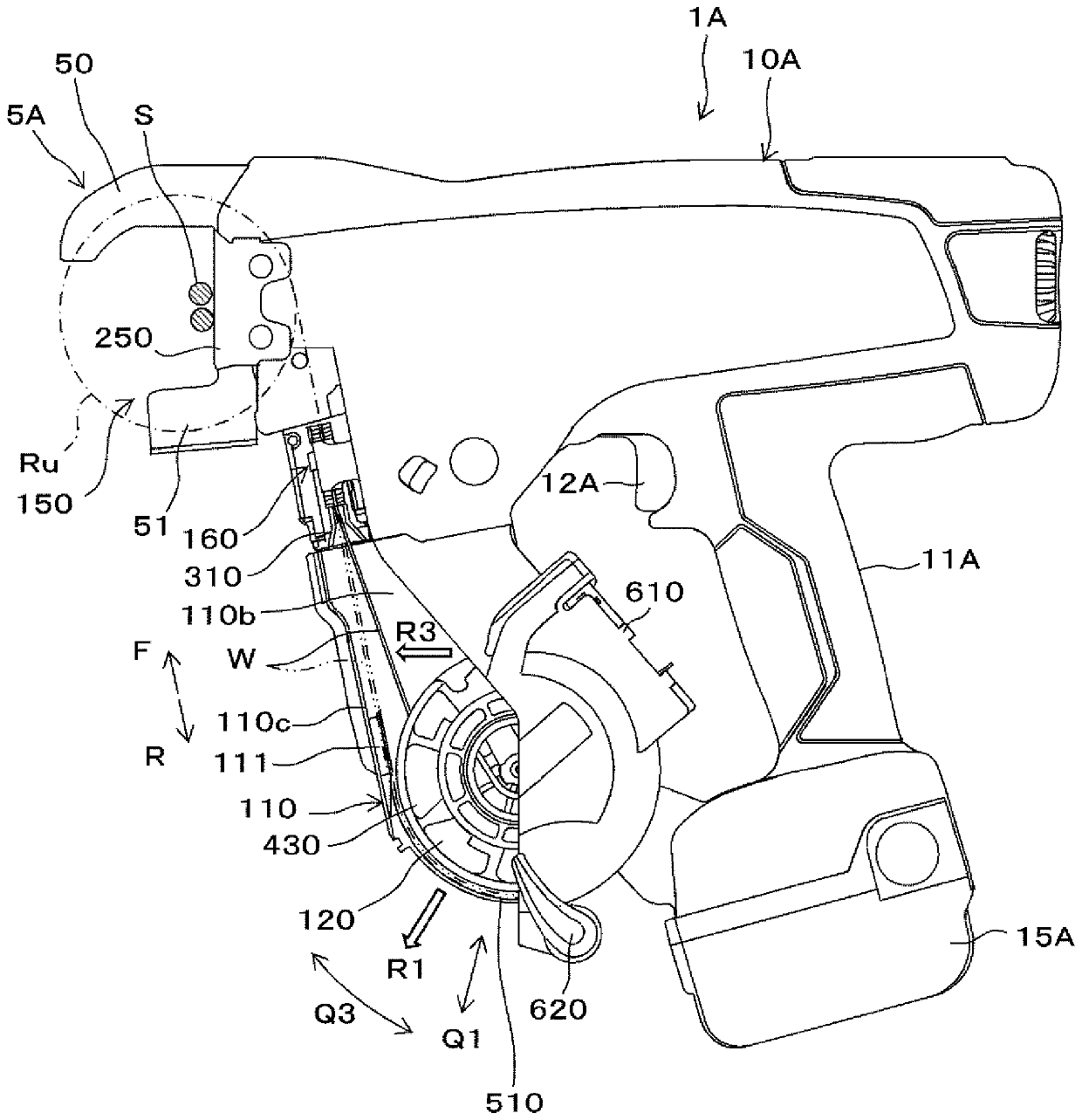

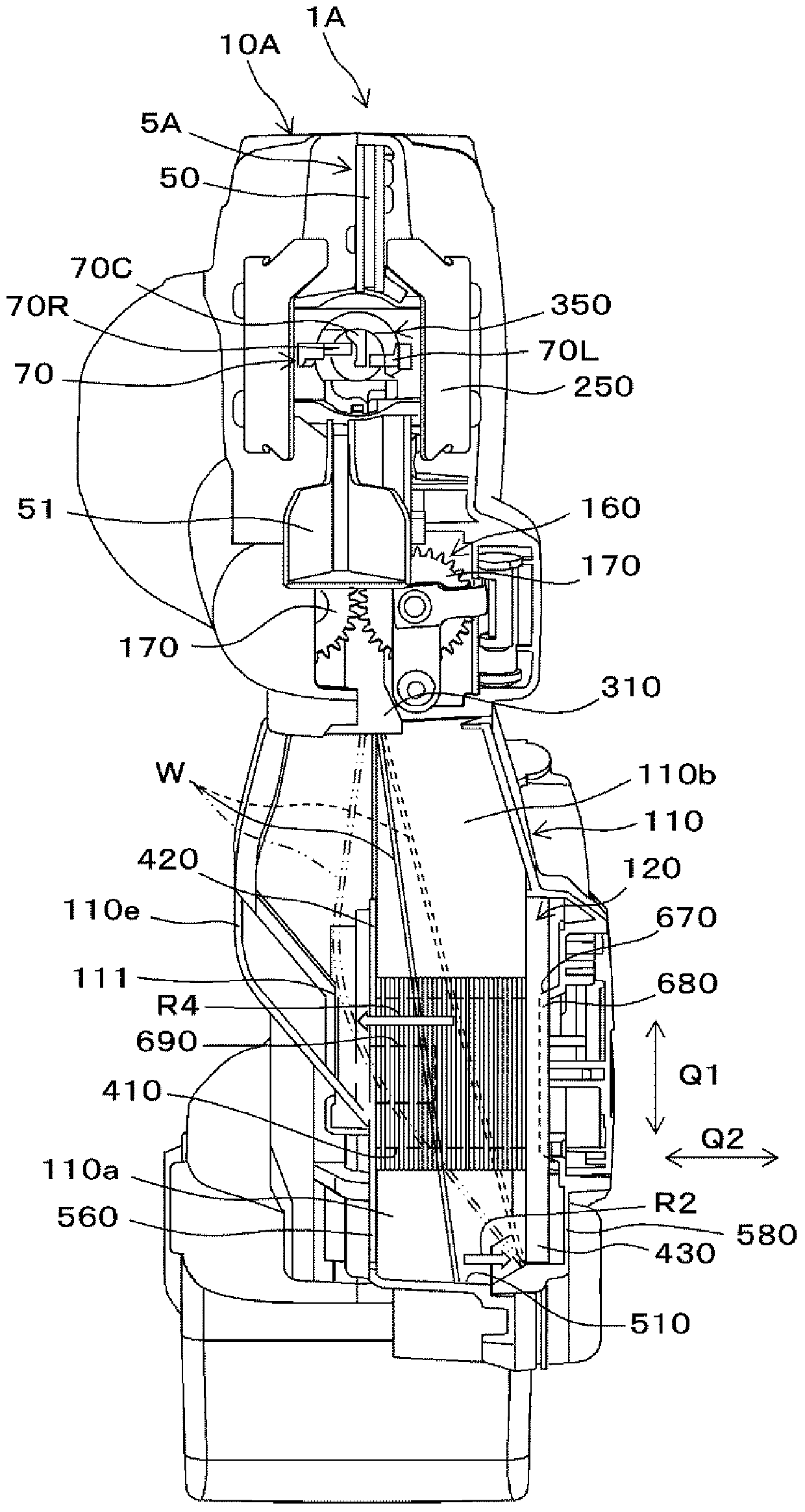

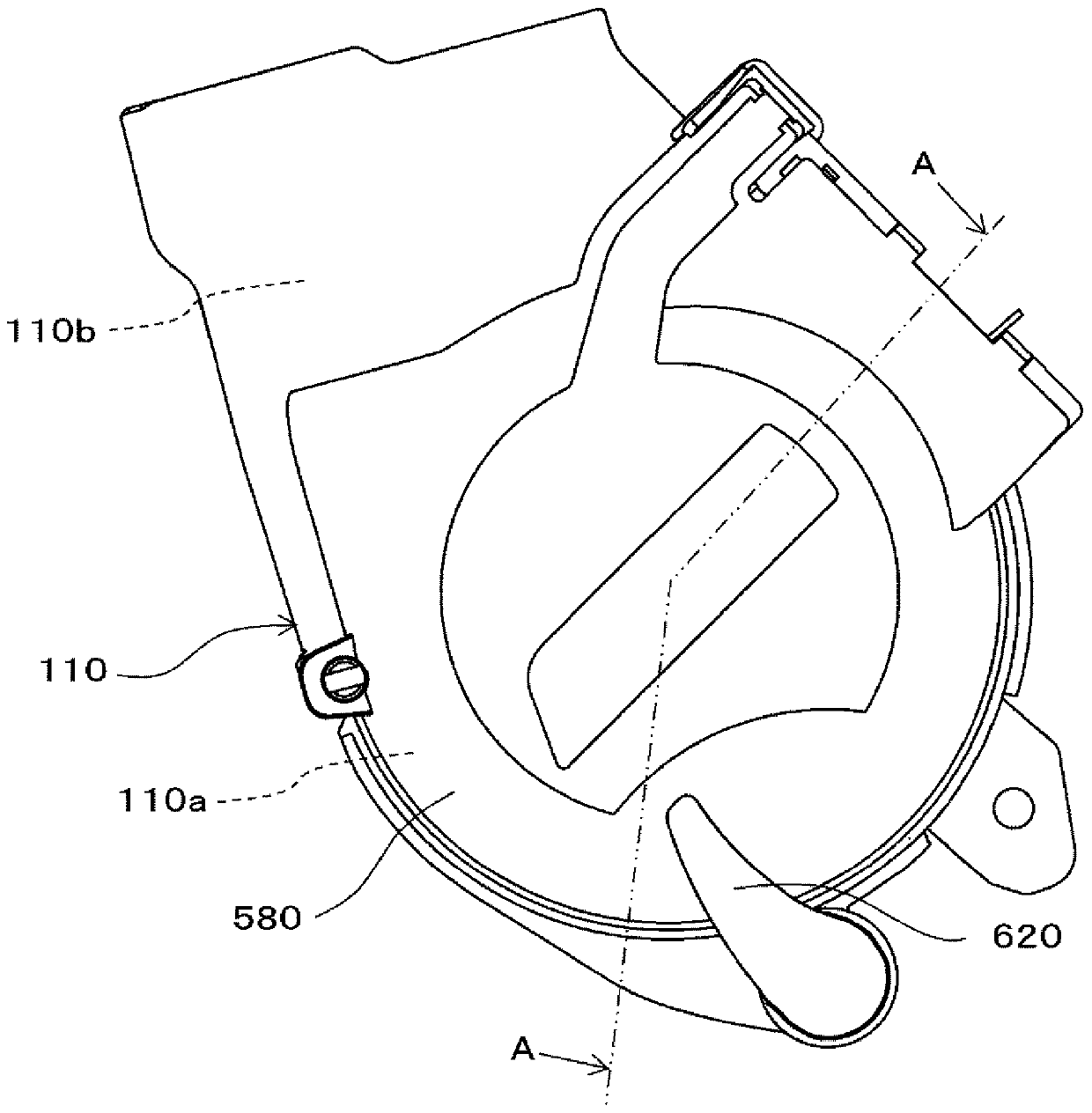

[0029] Embodiments of the binding machine of the present invention will be described below. Figure 1 to Figure 10 It is a figure for demonstrating this embodiment.

[0030]

[0031] Hereinafter, the structure will be described. Such as figure 1 side view of figure 2 As shown in the front view of , for example, a reinforcing bar binding machine (binding machine) 1A is used to bind binding objects (hereinafter referred to as reinforcing bars S) such as steel bars and electric wires at a construction site. This reinforcing bar binding machine 1A feeds the binding wire W in the forward direction indicated by the arrow F, and crimps the binding wire W while imparting an arcuate bending tendency to form a ring Ru surrounding the reinforcement S. Next, the binding wire W is fed in the reverse direction indicated by the arrow R to pull the binding wire W back, and the binding wire W is cut after the binding wire W formed into a ring Ru is wound around the reinforcing bar S. Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com