Gas-liquid mixing distribution system

A technology of distribution system and gas-liquid mixing, which is used in hydrocarbon oil cracking, hydrocarbon oil treatment, chemical instruments and methods, etc. Heat transfer efficiency, stable reaction and investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the drawings.

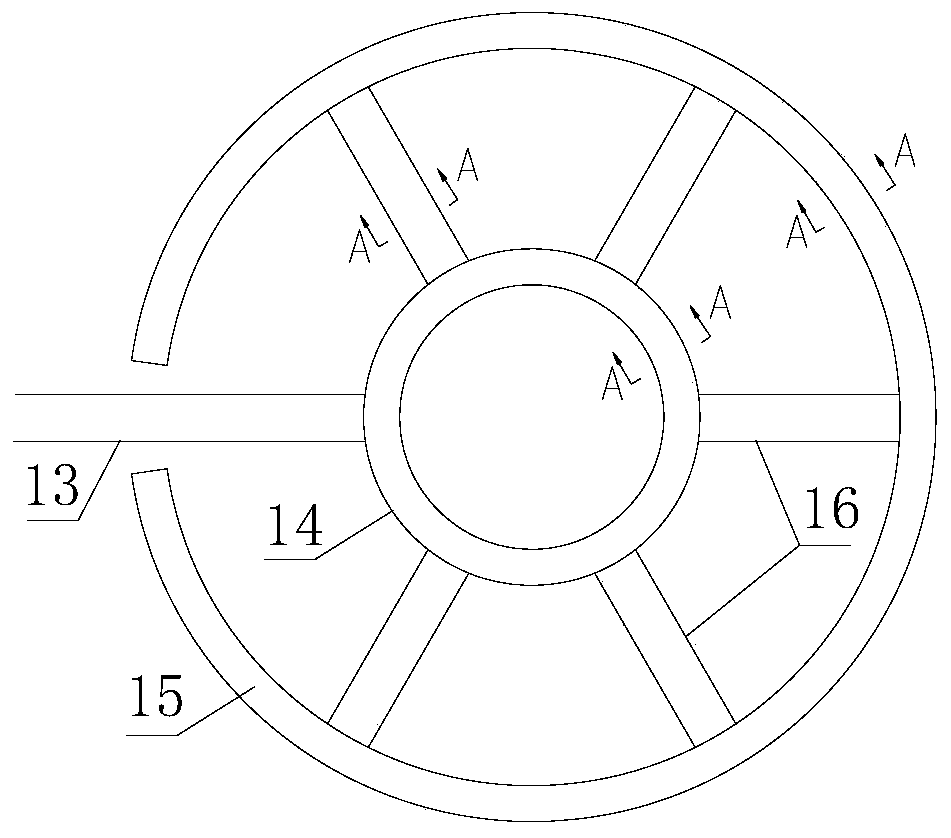

[0035] Such as figure 1 As shown, the gas-liquid mixing distribution system of the present invention includes a casing 1, a catalyst grid 2 fixed on the inner wall of the casing 1 and a catalyst grid support beam 3, and a cold hydrogen distributor support located below the catalyst grid 2 The cold hydrogen distributor 12 on the beam 4, the mixing chamber 11 located below the cold hydrogen distributor 12 and fixed on the collecting plate 5, the coarse distribution plate 6 located under the collecting plate 5, and the coarse distribution plate 6 located under the coarse distribution plate 6 and fixed to the distributor The gas-liquid distributor 10 on the disk 8; the distribution disk 8 is fixedly connected with the distribution disk support beam 7 and the inner wall of the housing 1 respectively, and the gas and liquid distributors on the distribution disk 8 are located on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com